Innovative filament producer colorFabb has introduced their very first soluble support material, DPA-100.

The Netherlands-based company has long been one of the more imaginative providers of 3D printing filament, having been one of the first to introduce materials specifically designed for 3D printing some years ago.

Soluble Support 3D Printing

The move by colorFabb echoes the recent trend in the industry towards soluble support 3D printing. In this mode, two extruders are used; one for the build material and the other for soluble support material. The soluble support material holds up overhangs in the target 3D model being printed, as would any support material.

The difference here is that the support material is dissolvable. Early support materials were simply rigid thermoplastics that had to be mechanically removed by hand. While that often works reasonably well, the issue is that the increasingly complex geometries used in advanced 3D print applications frequently require support “internally”. That is, support materials present inside the objects that are difficult or even impossible to reach. Thus standard support materials don’t really work, and sometimes the objects would be re-designed to avoid internal supports.

That all changed with the introduction of soluble supports, which simply melt away when exposed to a liquid solution. The liquid can reach into all crevices on the structure and, without human intervention, eliminate all the soluble support material. Not only does this result in a cleaner 3D printed surface, but it’s also far less labor-intensive: you simply dunk the object and come back for it later.

Sometimes the liquid solvent is simply plain water, but other soluble support materials require alternative solvents, like detergents. HIPS, when used as a soluble support material, requires Limonene to dissolve, for example.

Soluble Support Problems

There are several different soluble support products on the market, but most suffer from two key issues.

One issue is the tendency for the material to absorb atmospheric humidity. Like nylons, PVA, a commonly used soluble support material, quickly soaks up humidity and this results in increasingly poor quality prints. While it’s used only for support, you still want the supports to be strong during the print. That’s quite important when support structures are tall and thin.

A second and more problematic issue is temperature. Most soluble support materials have relatively low softening points. This means they are effective only for use with low-temperature 3D print materials such as PLA. If you attempt to use them with higher-temperature materials you’ll find the supports weakening and sometimes collapsing. For high-temperature 3D printing, there are almost no options available, as materials like PVA would literally melt at those temperatures.

DPA-100 Soluble Support

colorFabb’s new DPA-100 soluble support material attempts to resolve these issues.

The new support material does overcome the issues above. colorFabb says:

“Unlike PVA our DPA-100 is less sensitive to moisture uptake and offers better shelf-life and print performance over time. It is a Dissolvable Polyacrylate material made to work specifically with engineering grade materials which are not suited for PVA, like PETG, ABS, ASA, PC and PA filaments. We have extensively tested DPA-100 on various 3D printing materials available in the market, both colorFabb and non-colorFabb branded.”

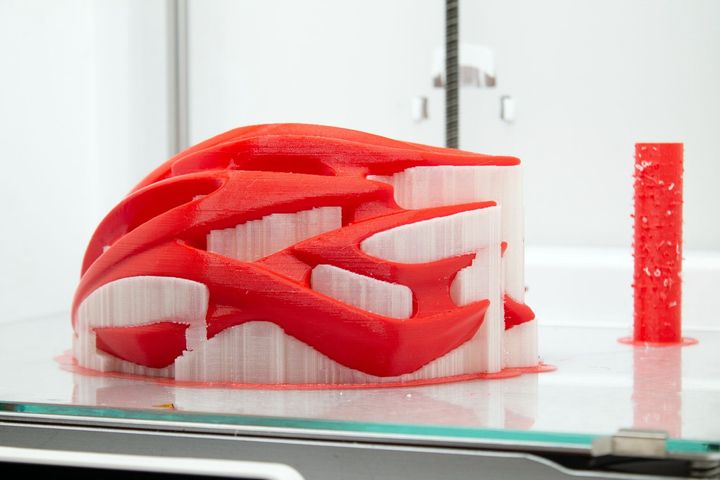

Here’s an example of how this support material could be used in a scenario that could not properly be 3D printed using conventional supports:

DPA-100 requires a nozzle temperature of 250C, far above many other soluble support materials. This makes it potentially usable on single-nozzle, dual-extrusion configurations where a nozzle is shared between engineering materials.

DPA-100 requires an alkaline solution to dissolve, one with a pH level greater than 10. You can produce this yourself, or use colorFabb’s new detergent product, “DPA Detergent”.

colorFabb says their detergent will dissolve a weight of support material on a 1:1 basis. Thus, if you have 1kg of support material to dissolve, it will consume 1kg of detergent. When this limit is reached you’ll need to replace the solution — but as they remind us, you must deactivate the alkalinity by adding some acid before disposing of the waste solvent.

Note that you’ll require a tank that can warm and circulate the solvent. While some workshops may have such a device already, it’s easy to create one with a simple tub and sous-vide heater as seen here.

DPA-100 Cost

While DPA-100 is currently available, it’s not inexpensive, as it’s priced at €120 (US$135) per 500g, or €240 (US$271) per kg.

If that’s too pricey for you, consider that some slicing systems allow for use of a soluble support only as a thin interface layer. In other words, the support material is the same as the build material, except for a thin soluble separator layer between the two. This allows for quick detach of the non-soluble support segments and saves a pile of money too.

colorFabb continues innovating, and I’m wondering what they will develop next.

Via colorFabb