Charles R. Goulding and Preeti Sulibhavi look at a new development in medical technology.

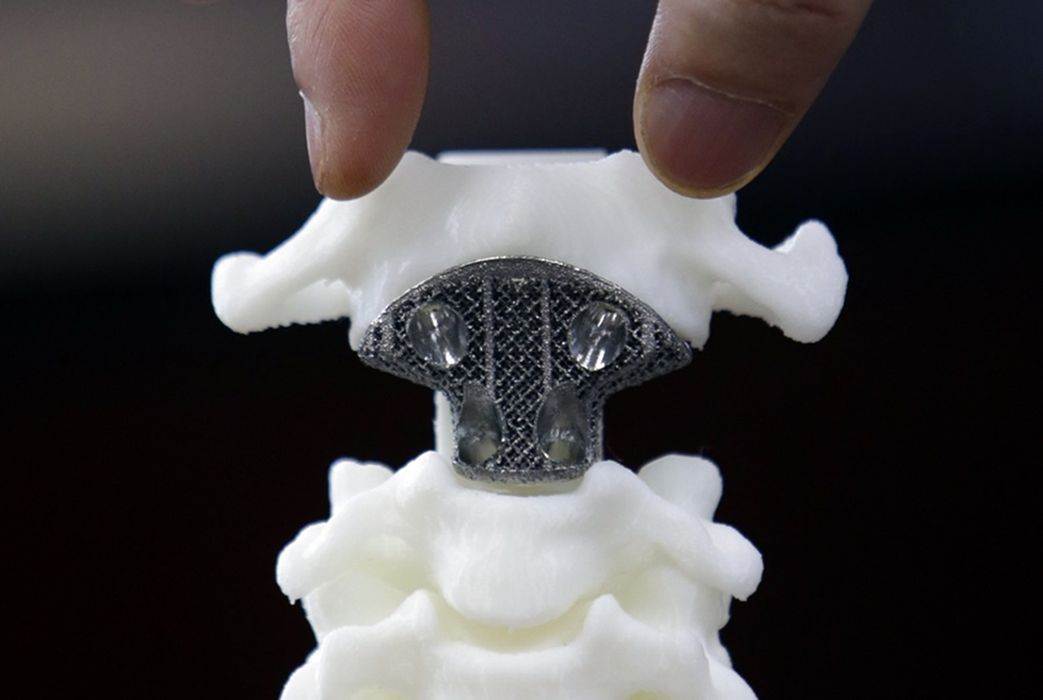

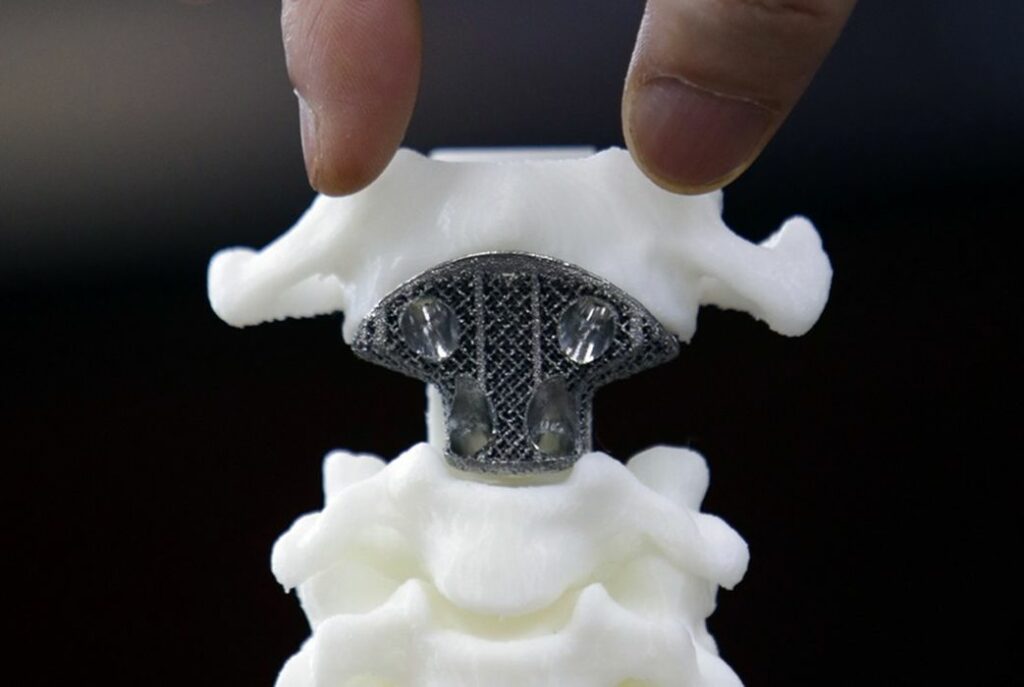

A spine model implant with a 3D printed artificial axis [Source: Jason Lee / Reuters]

The human body’s natural order is to reject implanted foreign objects. This poses a major challenge for the burgeoning field of 3D printed organs and a myriad of body parts including hip, shoulder, ankle, and knee joints.

Natural cell parts called platelets have always played a critical role in stemming the flow of blood from wounds and also supporting the regeneration of tissue. Now, Dr. Yunbing Wang of Sichuan University in China has used this concept to coat medical components with platelet membranes.

The initial experiments were done with platelet-coated stents and inserted into rabbits. The preliminary results look promising but it is clear that taking the leap from animals to humans is going to be an arduous task. Even so, Dr. Wang’s findings offer some exciting possibilities for the 3D printing medical device industry and were recently featured in Matter Magazine.

There are reasons for being cautious with using platelets in medical device implants. We have previously written about Dr. Paolo Macchiarini and his ground-breaking 3D printed bioartificial windpipe and its devastating impact on his patients’ lives.

This was a dire example of where 3D printing could not utilize the technology successfully in patients. That is why using platelet-coated stents and implants requires extensive testing and transparency with patients and the medical community to ensure proper health outcomes and minimize damage and harm to patients.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

As the 3D printing industry continually innovates its real growth potential will be temporarily constricted by the rate of progress in interdisciplinary fields such as material science and biology as illustrated with the platelet coating example. While the 3D printing industry continuously improves medical devices it should benefit from the process made in the adjacent life sciences field.