Charles R. Goulding and Preeti Sulibhavi discuss BASF’s disclosure of strong sales results for it 3D printing business unit, Forward AM.

For the first two quarters of 2023, BASF the large multinational chemical company has reported separate 3D printing business sales results for its Forward AM business unit. The results are strong with a 43 percent increase in first quarter sales and a 39 percent increase in second quarter sales.

It is unusual for a publicly traded business to report separate financial results for a specific line of business. From an accounting perspective, separate results are typically discouraged since it is unclear how intercompany sales are accounted for.

Profits were not reported and for a separate line of business, as they are more complicated to properly identify because of intercompany transactions and highly dependent on how corporate overheads are allocated.

From a marketing perspective, the separate line of business results highlights growth opportunities for new product markets involving advanced technology. Separate 3D printing business results demonstrate that BASF is a chemical company that has a role to play with 3D printing and Industry 4.0. It will be interesting to see whether any other large companies with 3D printing businesses like GE or HP take the same approach and disclose 3D printing line of business sales growth rates.

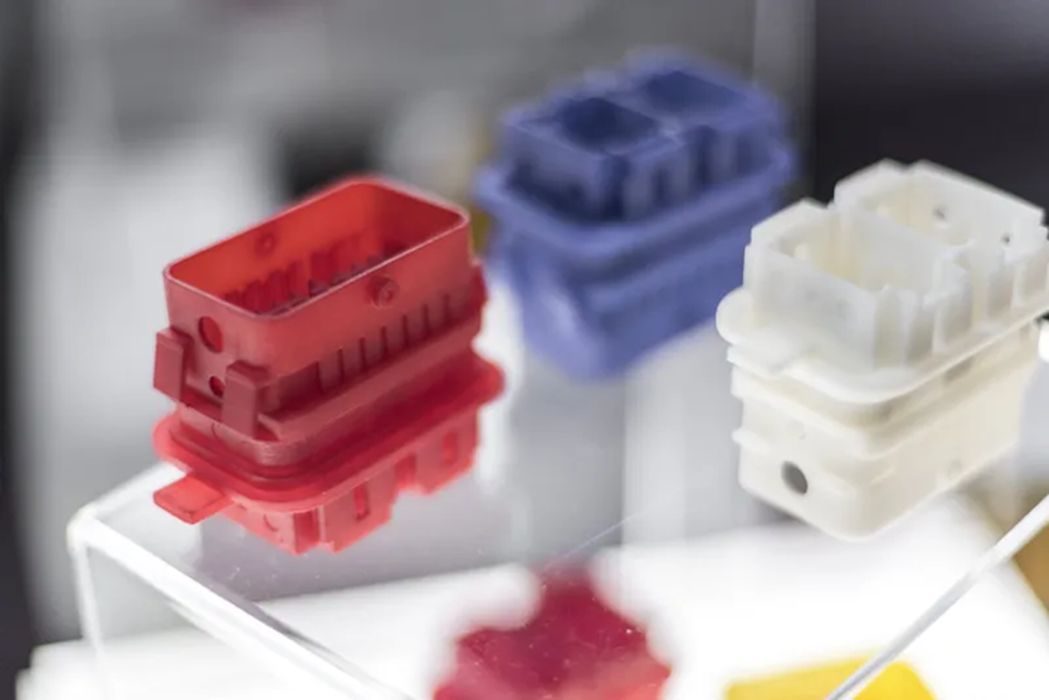

There are many uses for 3D printers in the chemicals industry. BASF has been accelerating its go-to-market strategy in 3D printing. BASF has partnered with Shapeways to allow the use of 3D printing to access Forward AM materials through a co-branded website.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

BASF has a long history of announcing its 3D printing accomplishments but the emphasis has been on new materials applications. With the German economy facing challenges it is nice to see BASF disclose its 3D printing achievements.