A new video shows the potential of large-format home 3D printing.

3D printing by consumers has been a thing since 2009, when the first inexpensive desktop 3D printers emerged. The idea then was that people could make their own parts instead of buying them from proper manufacturers.

From that concept investors swarmed the 3D print space, scooping up companies, products and driving stock prices through the roof. However, cooler heads prevailed when it was realized that consumers generally do not have the skills to design 3D models nor operate the typically-frustrating 3D printers at the time.

That’s still the case today, but instead of consumers using 3D printers as originally envisioned, there are instead hundreds of thousands of DIY makers who operate them to build all manner of ingenious items for use around the home and office. There’s even a dedicated Reddit forum for showcasing such designs.

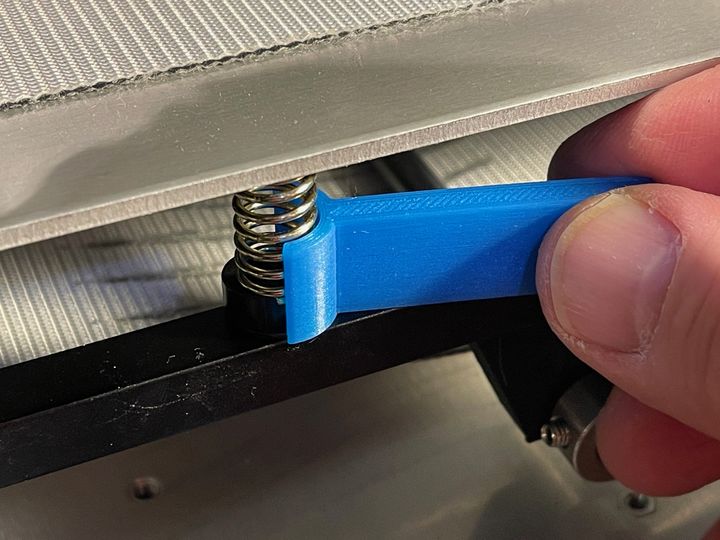

Most consumer 3D printer operators now make (and sometimes even design) objects for functional use. I do so on a regular basis, and last week’s design was a small jig I created to assist in building a machine:

It’s a very simple design, but in this case it saved me several frustrating hours of positioning impossible springs, spacers and washers. This is very typical: a need triggers a design to solve the problem.

However, all of these solutions have one common design feature: They Are Small.

These custom-designed parts obviously must fit within the build volume of the operator’s 3D printer, and even assemblies are typically not particularly large.

But then something happened: belt 3D printers arrived on the scene.

Belt 3D printers are a variant that has recently emerged. Instead of 3D printing on a fixed plate, the action takes place on a moving conveyor belt. While this enables automatic unloading of completed prints and continuous production of small items, the concept also allows for production of large parts that exceed the volume of the machine itself!

Those with new belt 3D printers have been busily 3D printing full-size swords, rails and other unusual objects. That’s all fun, but not particularly practical outside of the occasionally cosplay event. That is, if we were having events at all.

Our friend Joel Telling of the 3D Printing Nerd YouTube channel performed an experiment that just might change things in a “big” way.

Telling decided to 3D print an assembly (an articulated arm 3D model) on the belt 3D printer, but at 6X normal size!

After what must have been many days of 3D printing, Telling assembled the printed parts into the arm mechanism as shown at top.

I don’t know about you, but this feels very different. It’s far more than just a bigger item. Telling has produced a large apparatus that could perform functions well beyond the typical desktop-sized items 3D printed to date.

I’ve always felt that belt 3D printers will be a big thing in the future, and perhaps this video is the first true demonstration of this potential.

What does it mean if belt 3D printer operators realize they could produce large, structural items?

What on Earth will they design and build? Tools? Furniture? Dog houses? Vehicles?

Those aspirations may be tempered by two factors: time and money.

Telling doesn’t say explicitly in his video, but 3D printing all those pieces (and the occasional failure, too) must have literally taken a week or more to complete. That’s a very long time to wait, as compared to the 22 minutes I waited for my jig. Some inventors will be dissuaded from producing large items simply because of the time involved.

Money is also going to be a factor. I don’t know how much filament was used by Telling to produce those enormous parts, but certainly a couple of kilos at the least. Depending on the geometry, a large 3D printed part of this size could be a pricey item.

But that just means it had better be worth making it.

Via YouTube