Desktop Metal announced a very unusual 3D printer: the S-Max Flex.

This is a new device that combines technologies from Desktop Metal and their recent acquisition, ExOne to produce an inexpensive sand 3D printer.

Sand 3D printers are used by industry to produce molds capable of holding molten metal for casting. This enables foundries to produce parts with geometries impossible to make using conventional and expensive traditional molds.

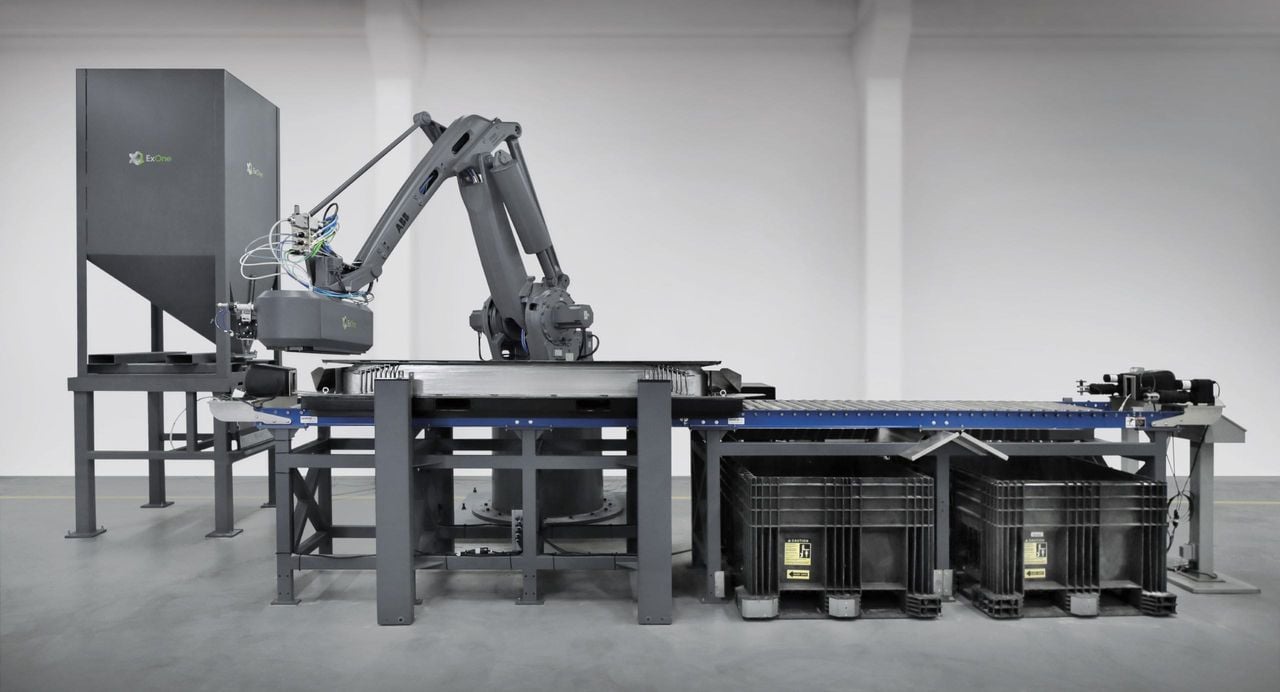

The new S-Max Flex doesn’t actually look like a typical 3D printer. Instead of a “box”, it’s a robotic system with a massive print head that moves along a pile of sand, jetting out binder that fuses sand particles together.

This is where it gets interesting. ExOne produced sand 3D printers in the past prior to the acquisition, but it seems that the two companies have combined technologies. Desktop Metal explains:

”The new S-Max Flex combines ExOne’s sand printing expertise in process and materials with proprietary Desktop Metal SPJ technology in an affordable architecture to deliver new value to foundries that have long wanted an S-Max but found the premium price out of reach.”

“SPJ” is Desktop Metal’s Single Pass Jetting technology. It’s previously been used in the company’s metal Production System, which by the way has recently hit the market.

SPJ is a variation of the well-known binder jet process. Binder jetting typically involves several passes over the print surface: depositing fresh powder; flattening the powder with a roller; selectively depositing liquid binder; post deposition treatments.

However, SPJ is an ingenious approach where all of these steps are combined into a single mechanical pass. This makes the printing far faster because each pass does soak up print time, particularly when you realize a part might require hundreds of layers to complete. Desktop metal produced an excellent SPJ overview you might want to review.

The new S-Max Flex incorporates SPJ in its sand printing process, making able to 3D print sand objects far more quickly. You can see the device in action in this video, note how fast it runs:

I find this development extremely interesting because it is a departure for Desktop Metal. The company has been on an acquisition streak in recent months, scooping up a variety of 3D printing companies with wildly varying technologies. This is quite unusual, as often acquisitions involve directly complementary or similar technologies that allow the acquirer to easily combine operations — or in some cases eliminate the competition.

I wondered what Desktop Metal was up to by acquiring many utterly different companies. At first, it seemed the company’s strategy was to merely rebrand them, as they did with EnvisionTEC’s gear, with some slight equipment tweaks.

But now it seems clear what’s really going on: they intend to combine technologies in a much more radical way. By combining technology from a metal printer with a sand printer they have come up with a very unique device that offers great benefit to a particular market segment.

With all those other acquisitions, I’m now wondering what Desktop Metal will do next.

Via Desktop Metal and ExOne