Tall 3D printing can be quite useful, but height can cause many issues.

Most 3D printers offer a cubic build volume of reasonable size, usually between 200-400mm on a side. However, there are some machines that offer taller build volumes.

A typical manufacturer’s approach would be to take their standard 3D printer model and “stretch” it. This is done by simply lengthening the Z-axis hardware. Many 3D printer manufacturers have done this, introducing an “XL” type model.

Some hobbyists have done their own conversions using this approach. Here’s an example of how Reddit contributor GiaoPham0403 modified a stock Creality Ender-3 into a tall 800mm device. One problem encountered was a requirement to tweak the firmware to allow the motion system to travel farther than 250mm.

But that’s not the only problem with tall printing. After seeing this extreme modification, I thought it might be useful to explain three common problems encountered when printing tall items using different 3D printing processes.

Tall FFF 3D Printing

It might be mechanically possible to stretch a FFF 3D printer in this way, but there will be a big problem: model sway when using i3-style devices.

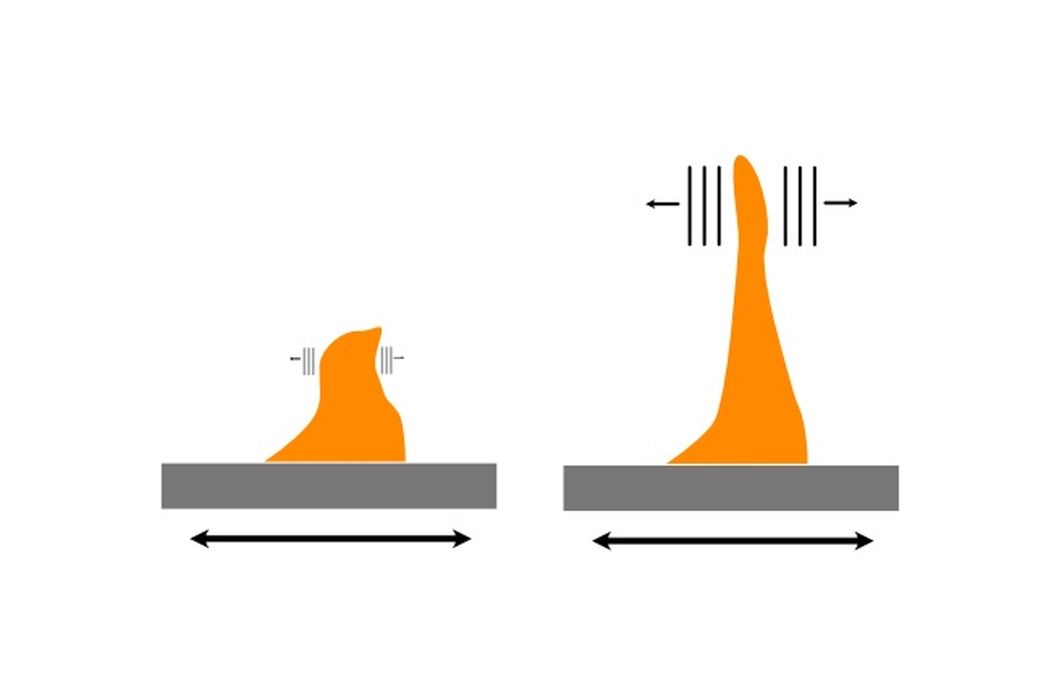

An i3 3D printer moves the Y-axis along the print plate. The plate literally moves forwards and backwards during printing. If the system is tuned properly, it should work fine.

But trouble begins when you get taller.

In “short mode”, the print sways only a little bit, and the offset from the model to the nozzle isn’t very much.

However, in “tall mode”, the model can sway considerably, and the offset between where the model is supposed to be and its actual position grows. This would certainly affect print quality, and in extreme cases such as the stretched Ender-3 above, might even knock the print off the plate entirely.

The effect would depend on the geometry, motion, use of supports and other factors. It might be possible to compensate for this with advanced firmware, but I’d say just avoid tall i3 printing.

Tall Resin 3D Printing

Can tall prints be problematic in resin 3D printing? Absolutely they can!

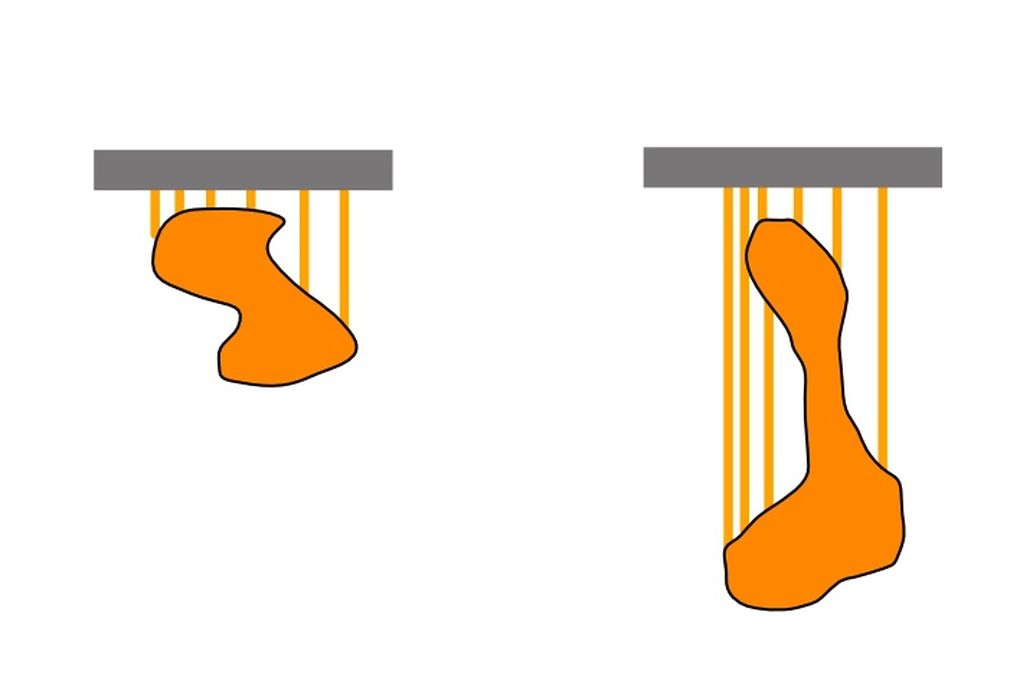

I’ve encountered this effect many times. While the plate isn’t moving as it does in FFF 3D printing, the apparatus is upside down. The model hangs down from the plate during printing.

Taller prints use more material, and thus become heavier as the print proceeds. This means that the support structures must be able to hold up that weight.

Many times I’ve scaled up a model and forgotten to thicken the support structures. This results in the model breaking off from the supports in mid-print, falling into the vat. The next layer’s processing will then crush the wreckage into your delicate FEP sheet at the bottom of the vat and you’ll have a bad day.

Tall LPBF 3D Printing

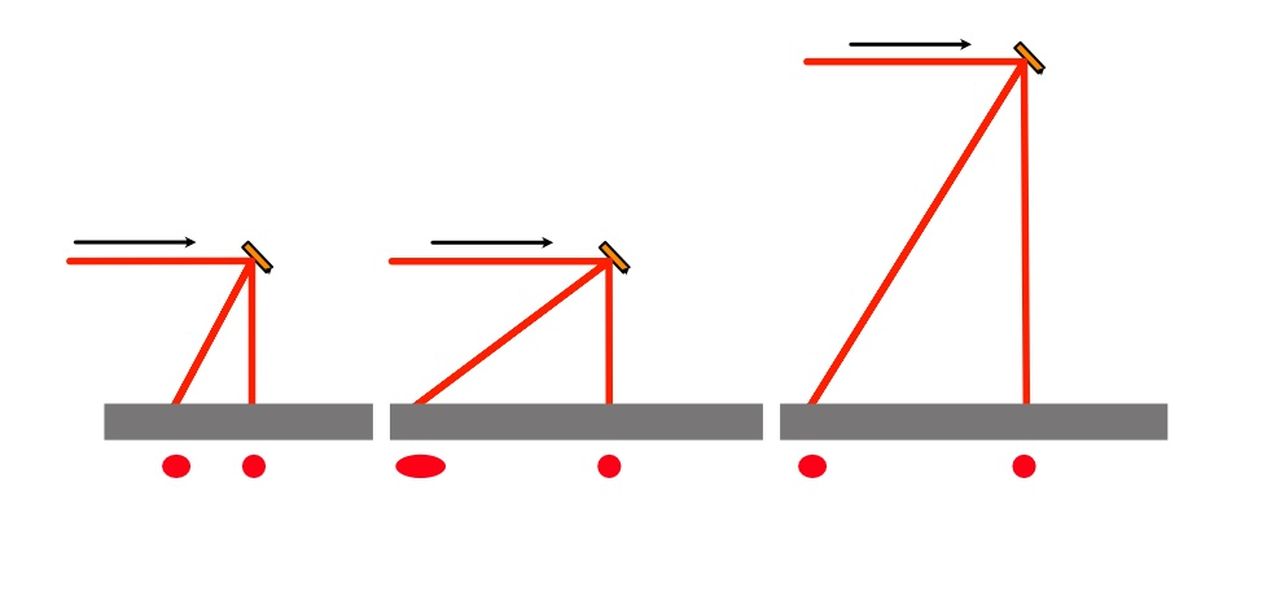

Tall effects also occur in LBPF 3D printing, where a laser is bounced off a galvanometric mirror at the top of the printer. The mirror is able to swing the laser dot towards any position on the print bed. The idea is to selectively fuse some of the powder, and do this layer by layer. This process is used in SLS, SLM, DMLS, and similar powder-based 3D printing processes.

But there’s a problem. When a larger build volume is required, the mirror must reflect the laser at a sharper angle. This causes distortion of the laser dot, and that’s bad. The energy in the dot is spread out over a larger area, making it harder to melt the powder. This causes all kinds of quality issues as the energy becomes variable depending on the zone of the print area.

The solution used by many LPBF 3D printer manufacturers is to make the machine taller! This positions the mirror in a place where the angle is decreased and the laser dot maintains a reasonable shape.

In the above image you can see a standard setup on the left, where the laser dot is reasonable in all zones. However, in the center configuration a larger build area results in a distorted laser dot. This is rectified in the right image, where the mirror is position high to reduce the angle.

The next time you see a tall 3D printer or print job, recognize there are almost certainly a number of unique challenges in making it work properly.

Via Reddit