Our review of the Creality Ender-3 V3 SE continues with a look at operations.

This is part two of a three part series, please read parts one and three.

Creality Ender-3 V3 SE Operations

Operating the V3 SE is done with the control panel. It’s not a touch screen, as Creality must have opted for a knob interface to lower costs. However, it works quite well and shows you the information required.

One interesting button is for calibration. It seems that you can have the print job perform calibration or not. If not, you save a bit of time on job startup.

I tried using the “Extrude” function to ensure I had loaded filament properly. This works just fine, but there is a bit of an issue: the printhead positions itself just barely above the print surface where you can’t easily see what’s going on. The extrusion process inevitably results in a poop pile that is so tall it actually touches the nozzle. The extrusion should take place at a higher position.

My first print was the “Creality Cat” pre-sliced 3D model that’s on the SD card. It worked just fine, and didn’t take too long to complete.

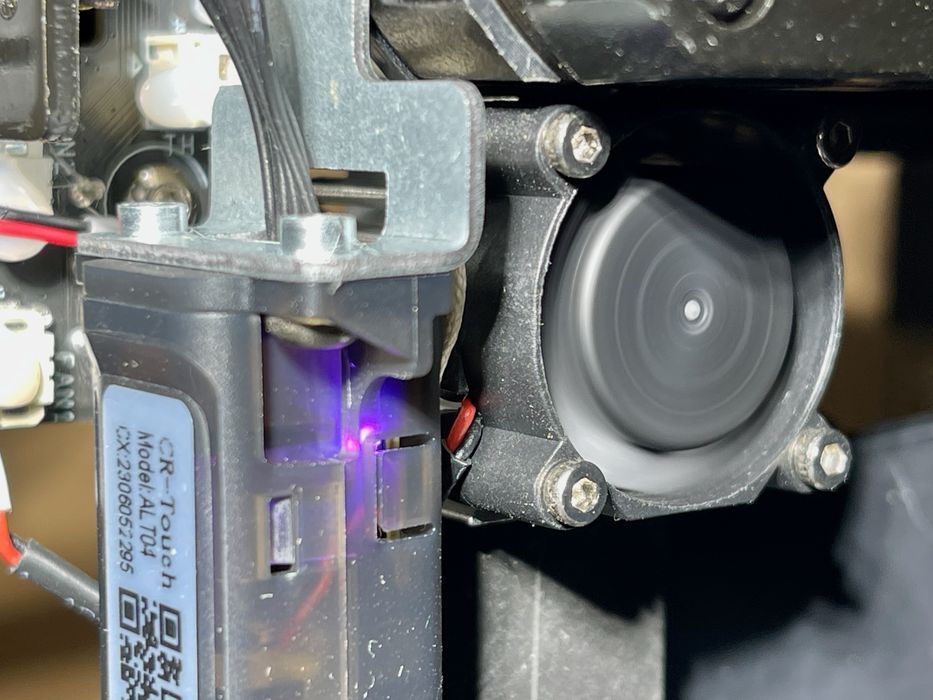

I noticed what I thought might be an issue. After the first layer when the fan speeds up, I heard an oscillating noise, no doubt from the fan. As layers proceeded and the fan speed increased, the oscillations disappeared.

I discussed this with Creality, who originally thought there might be an obstruction in the fan. However, after taking things apart, there was no obstruction and Creality explained that the sound was normal. I wonder whether this is due to use of a low cost cooling fan? Nevertheless, it doesn’t seem to affect printing or print quality at all.

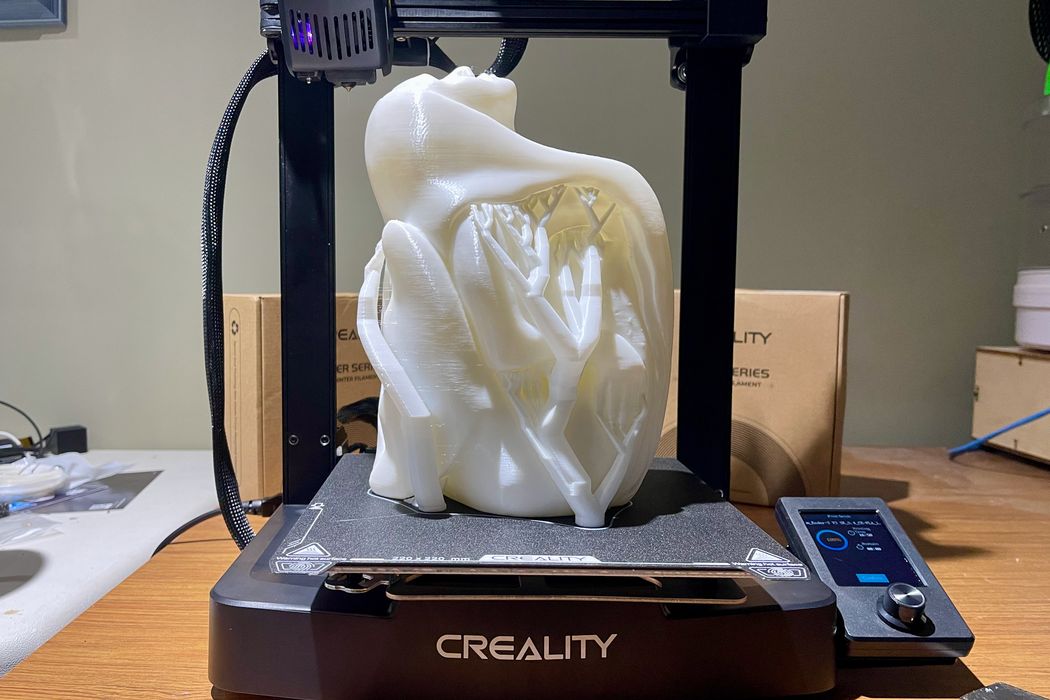

The V3 SE is capable of long, large prints. This item was a 17 hour job and is about 240mm tall. The V3 SE runs fairly quickly, as this print would have been a full day or two on other machines.

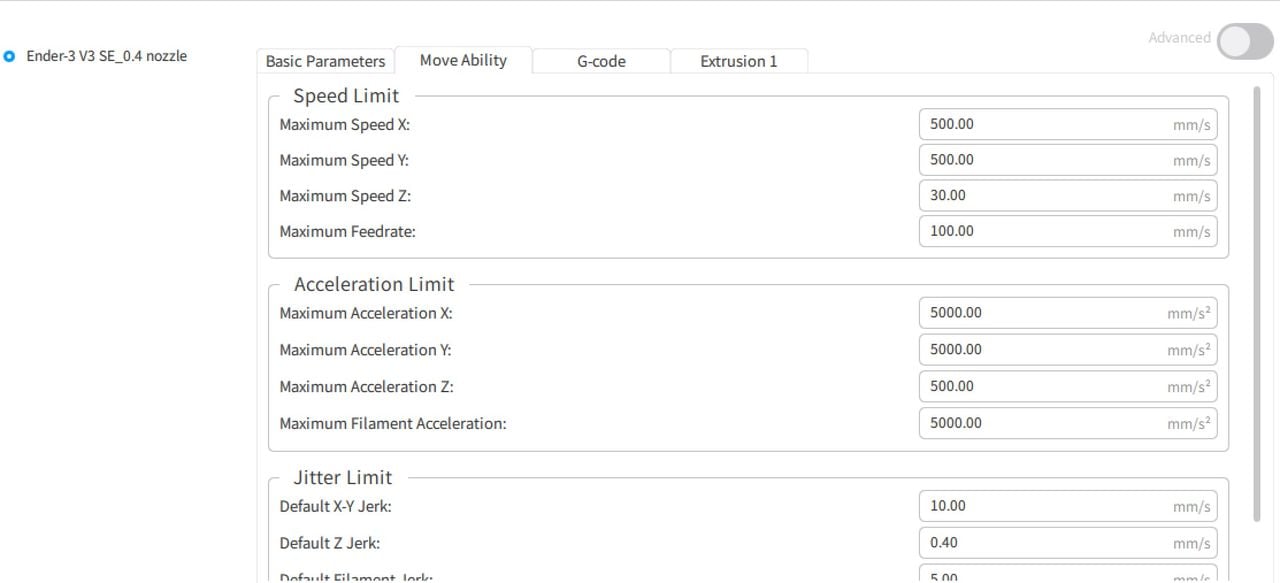

Let’s talk about the print speed for a moment. The machine profile lists the V3 SE as capable of speeds up to 500mm/s. However, that’s not the speed the device will achieve. Creality indicates that the highest practical speed is around 250mm/s.

However, in practice this is nowhere near the speed you actually print with. The print profiles are all set to a stock speed of 180mm/s, which is quite a bit faster than “normal” 3D printers, but slower than you might expect from a high speed 3D printer.

In other words, the V3 SE is “faster”, but not “fast” if you’re expecting a high speed machine.

One thing I continually noticed was how well the stock print profiles were tuned. Support material was extraordinarily easy to remove on every print. This is quite good because tuning the support settings is tricky, but Creality seems to have figured it out for us.

ender-3-v3-se-vase – 1

I printed a tall vase, and it came out ok. At least, I thought so initially. When I looked closely, I saw some odd blobs at various layer heights.

I asked Creality about this, and after some investigation they indicated that it could have been caused by the “Resume Printing function”. They recommended adding a “M413 S0” into the GCODE file after the heading. They provided some GCODE with this modification, and I ran it. As you can see above, the blobs disappeared.

This is quite an odd problem. I didn’t set any such function, so it must be a default. That was the only issue I encountered with the print profiles.

At one point I wanted to test printing with ABS. But as you can see on the screen, there was no preheat setting for ABS. What did that imply? I asked Creality and they said that while you could try to print ABS (or ASA), the machine isn’t really designed for that. They’re focusing on PLA, PETG and TPU only.

This is quite interesting, and implies they have a very particular target market for this machine that doesn’t involve engineering materials. While some may be disappointed by this, it makes sense for Creality. They’ve built a machine that does those materials, and does them very well.

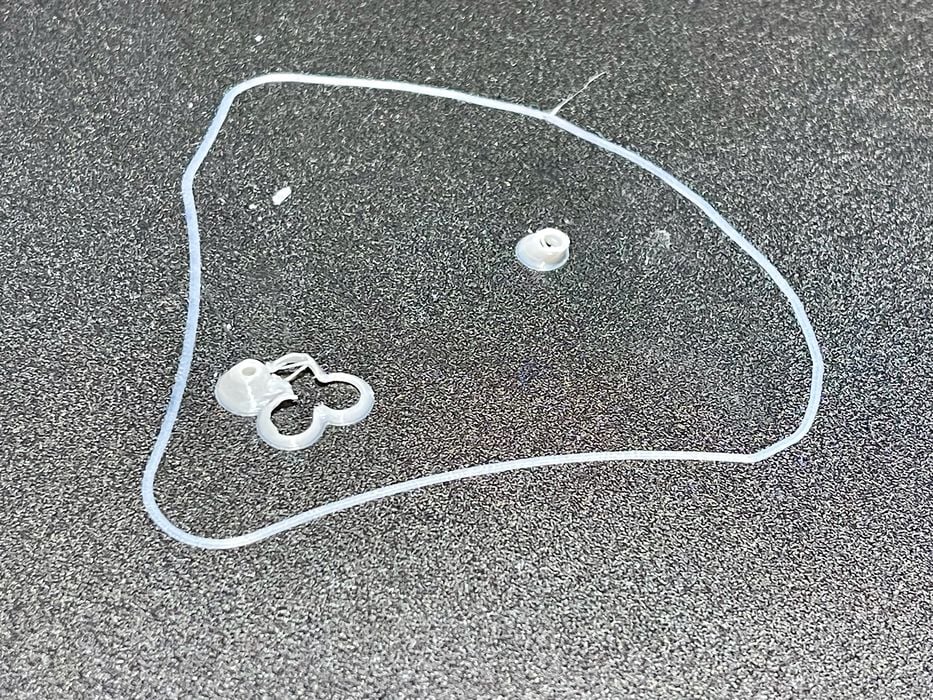

One issue I encountered was with the print plate. PLA sticks to the plate very, very well. Every PLA print required a very slow “peel” to remove them, and very often I had to resort to using a metal scraper to persuade the part to start coming off. Once I even injured myself when the scraper slipped, oops.

I have a habit of printing a one-layer skirt around my prints, but this is NOT something you should do on the V3 SE. The PLA sticks so well you basically can’t get them off. Even with careful application of the metal scraper there was always some PLA bits on the plate.

The plate sticks very well for PLA, but a bit less tight for both PETG and TPU. I was concerned that TPU would never come off the plate, but after some experiments in the corner of the build plate, they all came off easily.

This is part two of a three part series, please read parts one and three.

Via Creality