Our review of the Kingroon KP3S Pro S1 concludes with print results and final thoughts.

This is part three of a three part series, please read parts one and two.

Kingroon KP3S Pro S1 Print Results

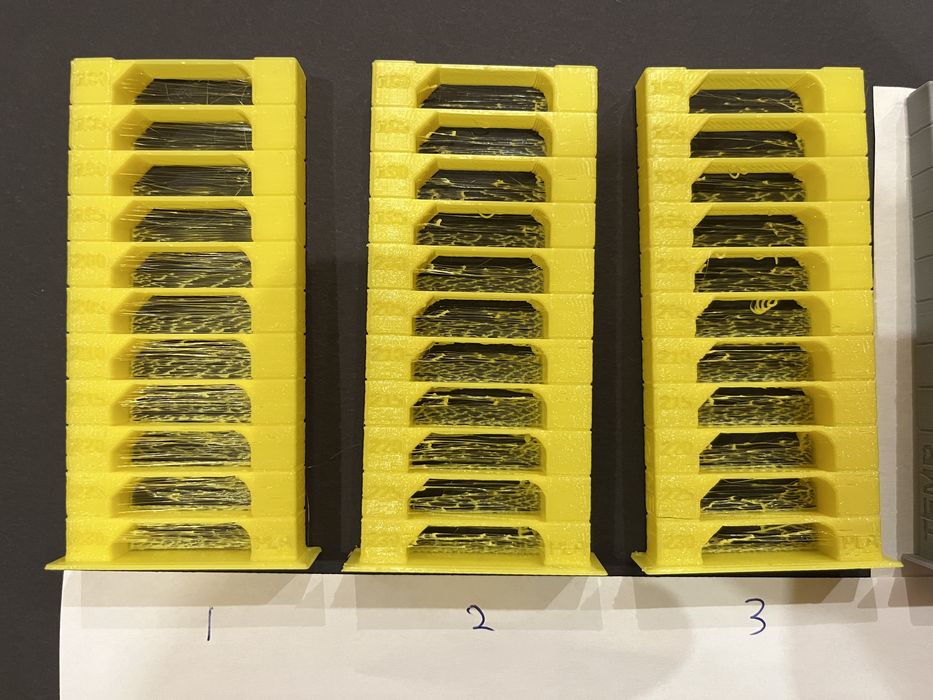

Armed with this setup, we revisited our yellow filament stringing problem. A CTRL-V test print sliced in Cura with both the yellow and white filaments was revealing — the yellow filament test showed pronounced stringing compared to the white filament variant.

Kingroon advised us to perform a few additional tests and concluded that the filament roll was faulty, not the printer. On a positive note, they shared customized filament profiles for PETG, TPU, and PLA to optimize our prints, a valuable addition that should be included on future SD cards sent with the equipment. We set the problematic yellow PLA filament aside for the moment.

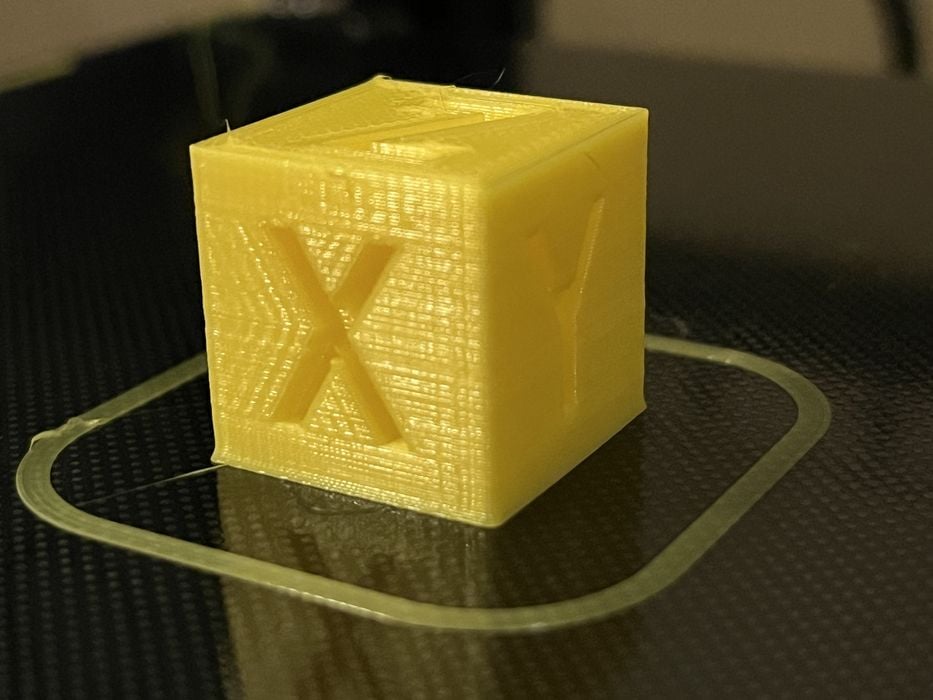

Armed with fresh PLA filament and the custom profile, our test prints proceeded quite smoothly, with minimal stringing.

The calibration cube exhibited slight ringing, and our #3DBenchy print was exceptional, even managing to render the stern text clearly, which is often a challenge.

Our Knurling Nut & Bolt looked impressive and spun together effortlessly.

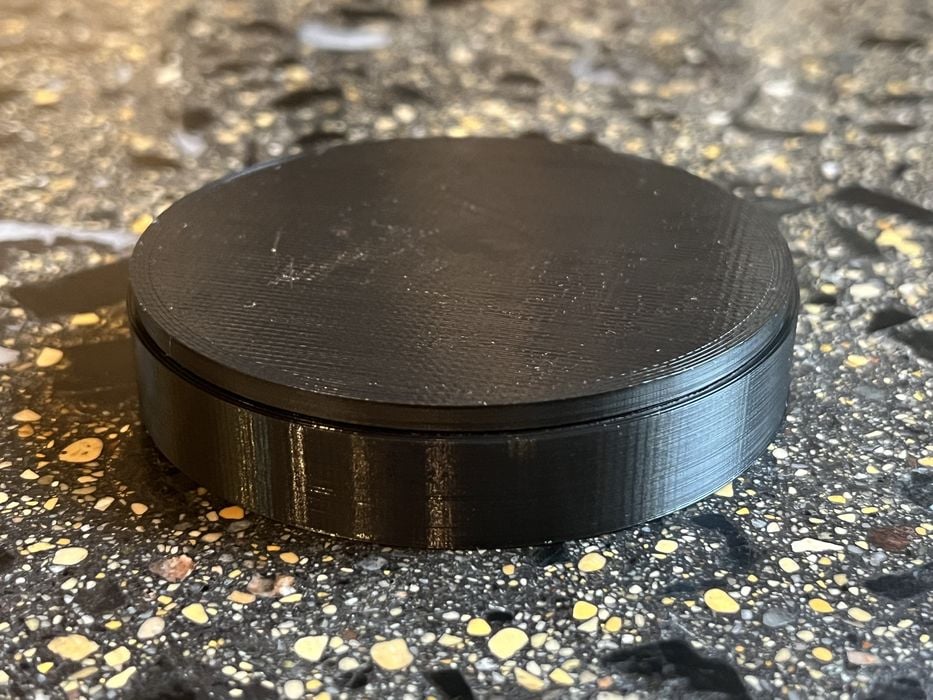

Despite a minor hiccup with our Cylindricity Test due to a slicing error, a quick fix ensured that the parts fit perfectly.

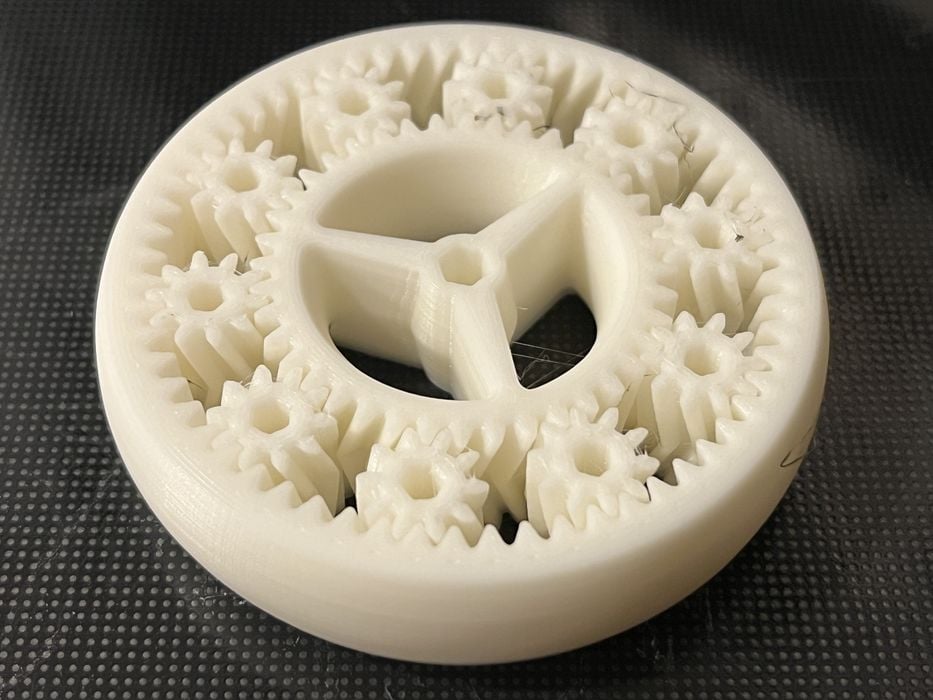

The print-in-place designs like Planetary Gears and PIP Spring Loaded Box operated flawlessly after some gentle nudging. Our Voronoi-style Lamp_3 was a complete success.

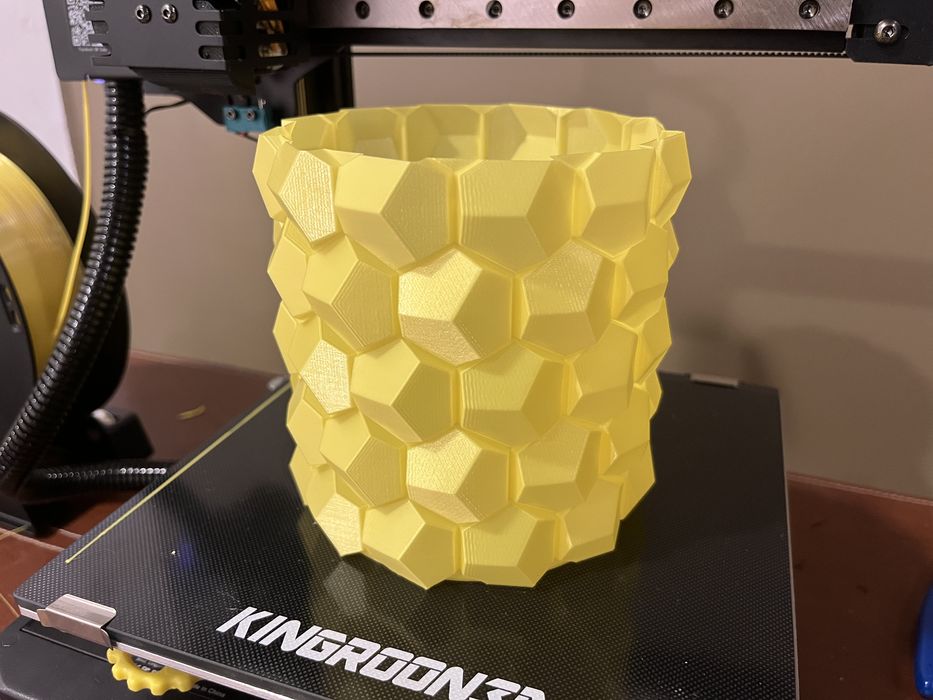

Our vase tests provided an opportunity to revisit the yellow PLA filament, as vase mode’s properties minimized the retraction-related issues.

The Spiral, Low-pot-poly, and Hexagon vases all turned out spectacularly, with fantastic surface finishes!

Our flexible TPU test ventured into new terrain as we attempted to print a replacement wheel for a vintage RC car.

The printer handled the flexible filament with ease, and the result was a perfect fit and operational wheel. It was fun removing all the support structures, however.

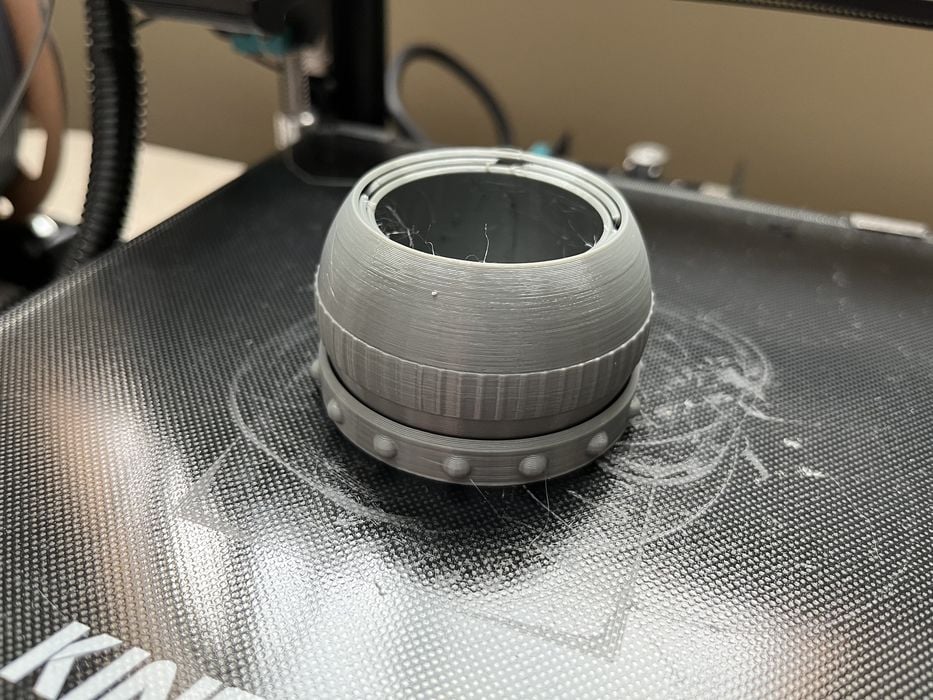

Our PETG prints included Carabiners and an articulating Eyeball 4_2 model.

Both required some gentle coaxing to begin articulating due to first layer material lodged in the joints — a situation where a firmware-based Z-gap setting could have been handy.

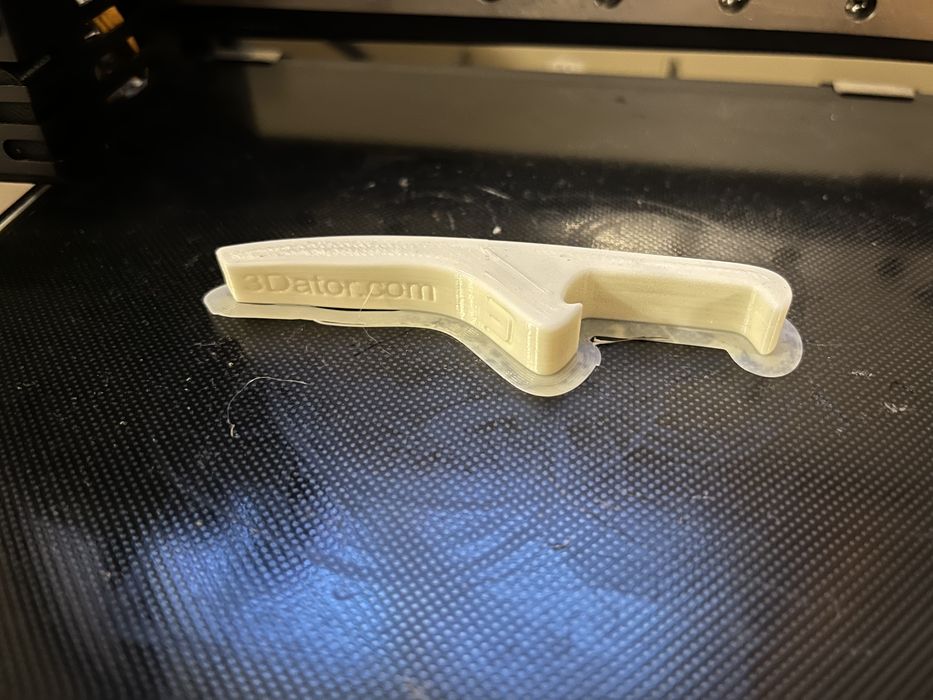

We tested ABS material on the KP3S Pro S1, even though it’s not explicitly advertised as being supported for the printer. Starting with the PETG profile, we adjusted the nozzle and bed temperatures and saving a new ABS profile, which allowed us to print a Carabiner and a Bottle Opener Whistle successfully.

However, we added substantial brims to counter ABS’s notorious tendency to warp on open-air printers. The final ABS prints exceeded our expectations.

Kingroon KP3S Pro S1 Final Thoughts

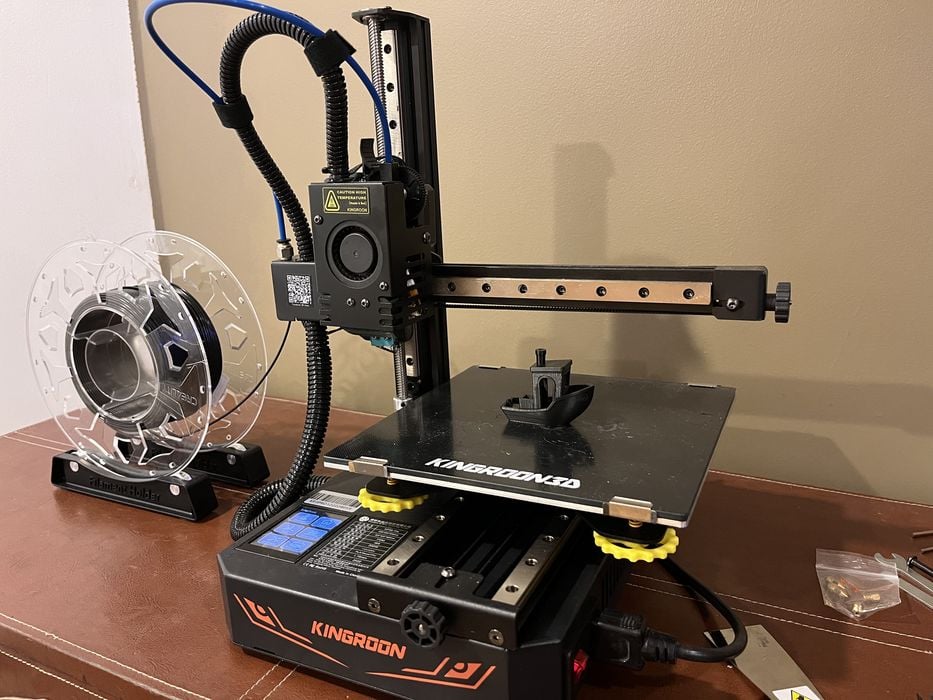

The KP3S Pro S1’s shipping packaging was robust, although a few zip ties to secure the main components during extraction from the box could have improved the unboxing experience.

The assembly was straightforward, albeit the build instructions and slicer setup could have been clearer.

Filament loading was a breeze, but entirely manual. An automated loading/unloading routine would have been welcome.

The skewed X-axis beam issue was quickly repaired, and including the procedure for doing so in future manuals could be beneficial.

While we didn’t face significant Z-gap issues after the initial leveling process, a firmware-based setting would have aided with the more complex prints.

The unexpected stringing issue caused by the faulty filament roll was effectively resolved, and we were particularly impressed with the vase mode prints.

While the printer lacked a leveling sensor, the small bed size, speedy five-point manual leveling, and flat glass build plate didn’t make us miss it much.

In conclusion, despite a few minor challenges addressed during the review, the KP3S Pro S1 delivered reliable, high-quality prints with decent dimensional accuracy. It performed admirably with PLA, PETG, and TPU, even demonstrating some success with ABS in our exploratory testing.

The support from Kingroon was impeccable as always.

Despite its limited build volume, the printer’s compact form factor makes it an ideal choice for hobbyists looking to explore 3D printing without needing extensive space.

Kingroon has done an excellent job with the KP3S Pro S1, and we await their next innovation.

This is part three of a three part series, please read parts one and two.

KINGROON

KP3S PRO S1 3D PRINTER

★ BEGINNER 6/10

★ ENTHUSIAST 9/10

★ PRODUCTION 7/10

BEST FEATURES

✔︎ Reliable support

✔︎ Print quality

✔︎ Quick assembly

QUESTIONS

✖︎ Vague instructions

✖︎ Manual load/unload

✖︎ Live Z-gap adjust

Via Kingroon