Charles R. Goulding and Preeti Sulibhavi look at the usage of 3D printing technology by the oil and gas industry.

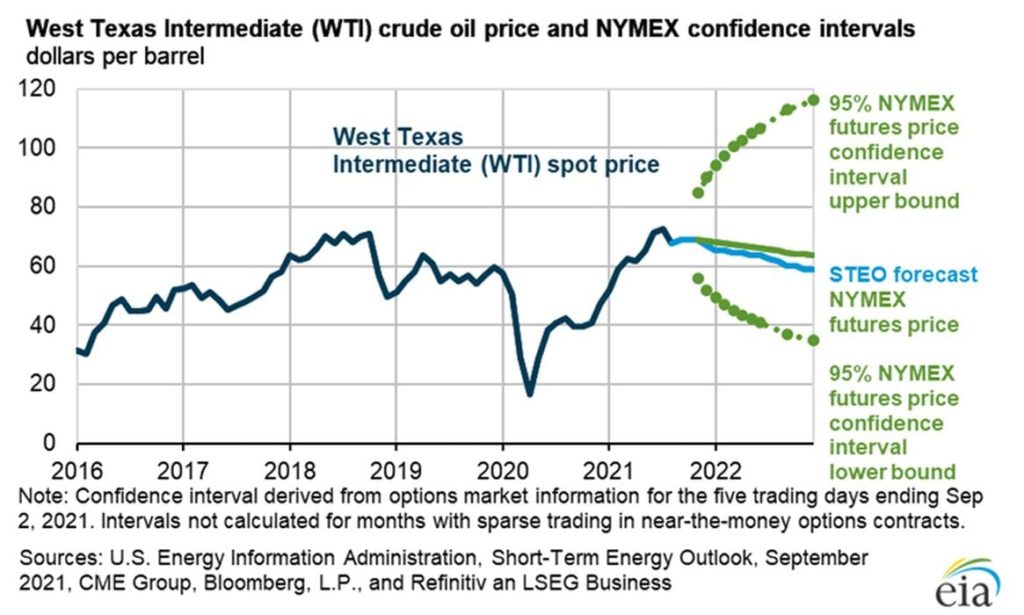

If you own a car or your house is powered on natural gas, you most likely noticed a rise in oil and gas prices recently. This rise has affected millions of Americans either at the pumps and/or when they are paying their utility bills. On Monday, October 11, 2021, U.S. crude rose 1.5% to US$80.52 per barrel, closing above US$80 for the first time since late 2014. It is likely, analysts predict, to go higher.

The oil and gas industry requires a tremendous number of new parts for both consumables and wear-ready parts. Requirements include pumps, valves, compressor components, fasteners, filters, seals and gaskets. Major suppliers with 3D printing opportunities include OEM manufacturers and numerous machine shops. With extensive field operations, the oil and gas industry is ideal for 3D printer mobile units that can fulfill on-site repair needs.

Oil & Gas and 3D Printing

We have previously written about mergers in the oil and gas industry. For instance, the fact that GE owns 37 percent of Baker Hughes was one of our previous articles on the subject. Even more recently, U.S. oil mergers have surged, thereby expanding customer opportunities for the 3D printing industry providers who are following the deal flow and events. As covered in a Reuters article:

“Total value of the 40 reported oil deals last quarter was $33 billion, estimated energy data provider Enverus Inc, up from $44.5 billion for all last year. The quarter’s seven $1 billion plus deals were mostly in Texas and Colorado oilfields but a fifth of the total value was spend on natural gas properties in the U.S. east, said Andrew Dittmar, Enverus’ senior M&A analyst.”

3D Printing’s Key Role in the Energy Sector

There are increasing energy applications for oil and gas 3D printing. The crucial application of 3D printing in the energy sector is in the spare parts market. The high cost of downtime and logistical challenges of distribution to widespread, remote locations creates a need for the correct parts exactly when needed. 3D printing provides a solution through fast, on-demand printing of legacy parts from an on-site system or a 3D printing service provider. Stratasys provides a detailed list of the critical parts that 3D printing can supply as presented below.

- Gas turbine nozzles

- SSD sleeve

- Sand control screens

- Nozzles for downhole cleanout tool

- Subsea chemical stick injection tool

- Sealing accessories

- Perforated pup joints

- Liner hanger spikes

- Drill bits

- Investment casting patterns

- Fluid/water flow analysis

- Turbo machinery

- Jigs and fixtures

- Rotors

- Stators

- Mud motor modules

- Flow meter parts

- Pressure gauge pieces

- Control-valve components

- Pump manifolds

- Spare parts

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies and startups developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Whether you are at the pump and notice filling your tank is not as economical as it had been, or if you are an avid follower of the commodities market, everyone can agree that a rise in oil and gas prices can adversely affect many people. 3D printing is a feasible alternative to fabricate many components in the oil and gas production industry and potentially help to drive prices down.