On the heels of Markforged’s announcement of intent to go public, we catch up with the team for an inside look at company strategy and what we can expect to see going forward.

Markforged to go Public

Last week, Boston-based Markforged announced its latest big move: working with special purpose acquisition company (SPAC) one to go public. The resulting NYSE-traded company (under MKFG) will be valued at over $2 billion.

It’s perhaps not surprising to hear that Markforged has had its look at opening up as a public entity, especially in light of other similar major moves in 3D printing recently. The additive manufacturing industry is consolidating and strengthening — it’s growing up.

Markforged has been signalling structural changes for a bit now, such as on the executive side. Founder Greg Mark stepped down from the CEO role, moving into a new position as the Chairman of the Board, as in October Shai Terem — who had joined the company in December 2019 as the new President and COO — assumed the CEO mantle.

Shuffling executive structure positioned the team as ready for next big moves. And so it was that the announcement of joining public Additive Manufacturing 2.0 companies was less of a surprise than a logical next step.

As always, though, there’s only so much we can understand of strategies at play from the outside. So I caught up today with Markforged for a look into the hows and whys.

Inside Markforged

I spoke with Michael Papish, Vice President of Marketing / Chief Evangelist at Markforged, for a look inside Markforged.

“Markforged has a really big vision for the future, for how we can reinvent and reconfigure how people build things. We really believe there’s a way to bring the power, the agility, and the responsiveness of software to the world of physical manufacturing. By doing so, we can actually change the way that manufacturers work and usher in more productivity, ability to meet consumer demand, ability to create more agile supply chains by using our platform,” Papish said in greeting. “We always knew to achieve our vision, to become a public company would be on our journey.”

In understanding the shape of industry and, perhaps more importantly, industrial revolution, the team at Markforged took into account what great change requires. For the most part, that’s time; the last Industrial Revolution didn’t happen overnight, and neither will the full hold of Industry 4.0.

Additive manufacturing has been maturing for years now. Markforged has been along the ride for seven years, establishing a foothold and working toward industry leadership. While the global pandemic that took hold over the last year was unpredictable, Papish also pointed to its importance as an accelerator — not only for 3D printing adoption, but for Markforged.

“When you’re in the middle of an inflection point, it’s hard to put your finger on it — but now seems like a time when people are questioning the orthodox way of doing things. We can think of the pandemic as a giant wave that wafts across all of society and disrupts it in ways you can’t predict. But humans are resilient, we find a way, it causes us to find new solutions. I’m not going to claim a pandemic is causing the future wave, but it’s accelerating what here at Markforged we’ve already been participating in,” Papish said.

It’s moving not just faster, but perhaps irreversibly as new ways of making are taking hold. Papish continued about why we’re currently at a tipping point for manufacturing:

“We’ve seen what happens when you organize your supply chains around lowest-cost production of uniform parts and not really around resiliency, adaptability, or responsiveness to consumer demands and the world around us. You need to set your company up to adapt quickly, which I think will really drive interest in digital manufacturing going forward.”

Markforged SPAC Strategy

For Markforged, catching that wave is keeping them not only afloat, but thriving. As more strategies evolved to adapt, Markforged simply adapted timing.

“We always knew that to get where we need to go, we would need to go public, to raise our profile, to have a larger set of resources,” Papish observed. “That moment has been brought in faster than expected.”

Still, it is not derailing the established company strategy. At the start of the year, Markforged laid out its plan for the year — and “nothing” will change about it. Rather, the word is, again, acceleration:

“The announcement we made last week will help accelerate that, provide resources to do that. But it’s the exact same plan we’ve been working toward,” Papish said.

So far as the decision to go with an SPAC merger rather than a traditional IPO, it turns out timing is at the root there too. One of the primary SPAC advantages Papish laid out is that it’s fast-moving. In a previous role, Papish experienced the “long process” of going public via IPO, which “can be distracting while running your business.” Working via SPAC “lets us get right on track” without a hiccup.

The move to go public is also of strategic importance for Markforged as a milestone, not in itself a goal.

“It’s super exciting we’re going public, that we get to work with the amazing team at one, and have a really great set of company resources to achieve what we need to do,” Papish said. “But that’s not our goal; our goal is to reinvent manufacturing, and these are steps toward that.”

Working with one “also allows us to tell our full story,” he added. Whereas in a traditional move, “you’re fairly restricted for your future plans,” the SPAC merger allows for more public transparency. The investor presentation Markforged released last week, for example, could hare a fuller vision of the company roadmap “where in a traditional IPO we may not have been able to do that.”

Working with one is also proving valuable to the Markforged team. Kevin Hartz of one is taking a seat at the Markforged Board table, bringing direct access to expertise and experience. Shared values between the two teams — particularly the focus on “the value of the team” itself — will enable a strong, ongoing meeting of the minds.

“What we’re doing here at Markforged is bigger than just running a business and growing, it’s about changing the way the world of manufacturing works. That’s an audacious challenge, making change in an industry like that will take time, perseverance, conviction,” Papish said of the bigger picture.

“I think we saw a very similar worldview talking with Kevin and the one team with this idea that to change the world you have to have a big vision then figure out how to operate your company. One differentiation at Markforged is believing in continual change, we’re not taking moonshots here. We’re delivering value today to 10,000 companies, reaching revenues of $70 million per year. That’s because we’re solving real problems. I don’t believe there’s any shortcut for that. The way to the future is one customer at a time, solving one problem at a time, and if we succeed in that we can evolve manufacturing.”

Markforged Future Plans

With the announcement, Markforged is continuing on its roadmap — and evolving its plans along the way. In this company’s case, that means more investment in R&D as well as in company growth. I asked whether that would mean another growing approach in 3D printing today: should we expect to see merger and acquisition activity?

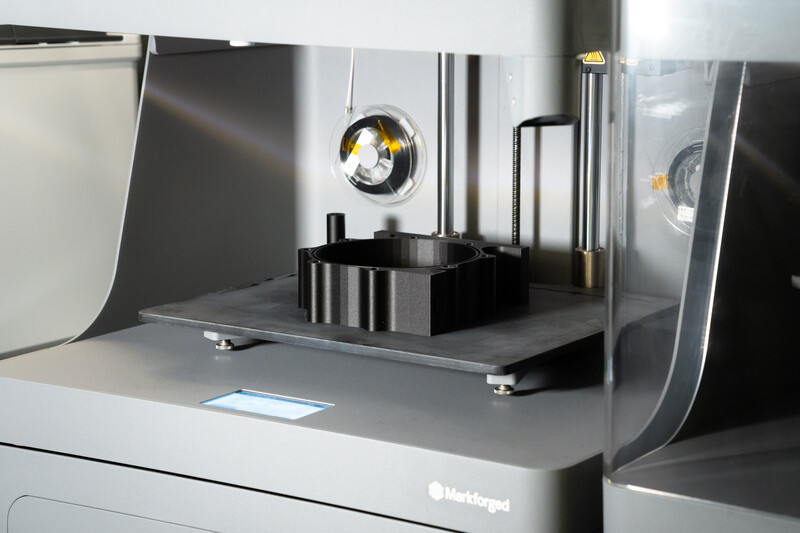

“That is certainly part of our plan,” Papish confirmed. “It’s not the only part of our plan and we’ll certainly look pretty carefully to make sure companies we might consider to bring on board fit with our culture, belief in technology stack. At the end of the day we’re not a company making a collection of 3D printers, we make a platform, and it’s all tied in together as the Digital Forge.”

Platform thinking informs the moves that Markforged is making today: what makes sense, how does it fit in with everything else the company has already done, how does it serve customers.

“We’ll use the funding we’ve announced to supercharge our platform so we can continue to scale it to meet the needs we see from our customers in the future,” Papish said.

Looking ahead to the rest of 2021, we can definitely expect to hear more from Markforged.

Some previews Papish was able to share include more machine learning, including from sensors already integrated into the company’s installed base of systems. Sensors on the X7, for example, allow for real-time part inspection. Data from real-world customers — who, to date, have 3D printed more than 10 million parts — will be used to continue to improve system performance.

“The next wave of innovation you’ll see is using this data, using smart algorithms, AI, machine learning, to start taking this data to really close the loop in manufacturing,” Papish said.

Markforged is also focusing on three dimensions of improvement for its 3D printers:

- Print faster

- Print more precisely, more accurately

- Print bigger

“As we’re able to make each of these dimensions better we can open up more applications for our customers. We’ll push the envelope in those three dimensions, more that we can solve for customers,” Papish said.

We can also expect to hear (quite soon, might I add) more about strategies involving the company’s go-to-market model.

“In addition to focusing on R&D, engineering, and software, our focus is also on optimizing our go-to-market model. We are really students of this industry, we are people involved in the world of additive for a long time. One thing we really want to do is bring the best of go-to-market models we’ve seen in capital equipment and in additive to us. We want to understand how hardware is sold across industries and bring that into our company. We’ll optimize for global distribution using what we think is an efficient go-to-market model to grow sustainability over time,” Papish said.

Overall, the vision is pretty clear at Markforged:

“We want to have a great product. We want to deliver that product to our customers. We want to make sure our customers are happy. If we can do that, nothing can stop us.”

Via Markforged