There’s more evidence of microplastics causing negative effects, which will eventually affect 3D printing.

Microplastics were not a thing years ago, but the concept is gradually coming into public understanding. The idea is that discarded plastics break down into smaller and smaller pieces through weathering and other effects. Eventually they become “dust” and begin to move around the world.

The smallest particles become airborne, and can therefore reach anywhere on Earth. Microplastics have been detected in Antarctic snow, for example. Drifts of microplastic have been found in urban river bottoms. This stuff is everywhere!

Obviously, this isn’t a good thing, but a number of recent research papers suggest that things are going to get a lot worse.

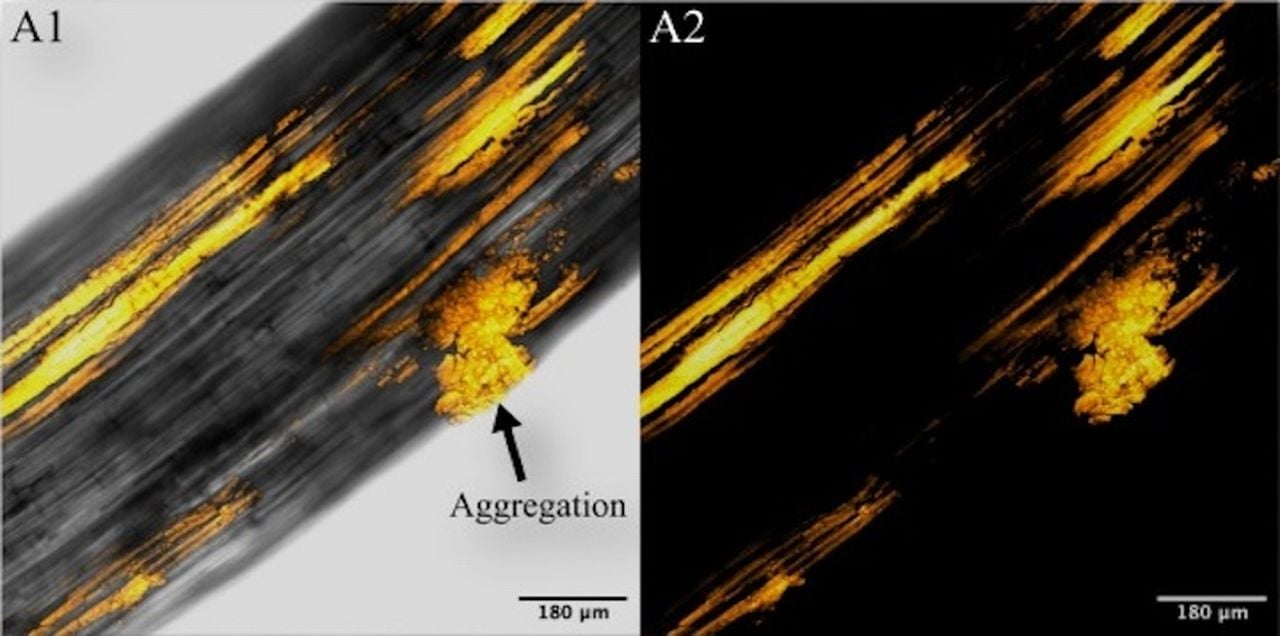

Several papers have determined that microplastics found in the environment can make their way into plants. The studies show that while microplastics tend not to get absorbed, smaller nanoparticles can. Microplastics eventually break down into nanoparticles, as these bits always get smaller.

The studies showed that foliage tends to absorb something between 10-20% of the absorption rate found in roots. Smaller, but still disturbing.

The implication here is that the food you eat, regardless of where it was grown, more than likely includes chemicals from microplastics. And it’s not just you: it’s anything that eats plants. That would include animals, some of which are consumed by humans.

It’s not yet clear whether the dosage levels are sufficient to cause problems, but I’m pretty certain this is being investigated by multiple researchers today.

In the event that this negative effect is proven true and becomes widely known, there could be an effect on desktop 3D printing. 3D printers are well known to produce copious quantities of waste plastic, virtually all of which will end up as microplastics sooner or later due to poor or absent recycling abilities.

For quite a number of reasons, it is unreasonable to expect a miraculous method of recycling desktop 3D printer waste. There are too many types of materials, colors and other issues to make it practical. I believe the only practical solution to this potential issue will be a widespread switch to properly biodegradable plastics.

I believe that it is possible to achieve this switch. PLA, a non-fossil-fuel sourced material that is the primary 3D printing material, cannot be easily be recycled or biodegrade on its own.

The only reason PLA is used is because it works well when printing and is available everywhere at reasonable cost. The vast majority of desktop 3D prints do not require any specific engineering materials, as operators simply want the digital geometry in solid form.

That’s why I think a switch might be possible: the material doesn’t really matter for many desktop prints.

However, a switch would not be easy: a new truly biodegradable — and printable — material must be identified and somehow become a de facto standard among FFF 3D printer operators. There seems little immediate motivation to do so at this time.

It may be that a forward-looking filament provider might develop a new material for this purpose in anticipation of future demand.

The demand will come; it’s just that we don’t realize how bad things are at this point. Later, we all will.

Via Science Direct and Frontiers