Charles R. Goulding and Preeti Sulibhavi examine the importance of 3D printing technology for post-war reconstruction and how it can aid Gaza’s rebuilding efforts.

As the Israel-Hamas war wages on, talk of a ceasefire and potentially ending this bloody conflict offers a glimmer of hope. When the dust eventually settles, Gaza will be faced with a tremendous rebuilding effort. Housing infrastructure, hospitals, roads, bridges, and transportation links demolished by bombing will need restoration. Careful consideration must be taken to avoid mistakes made during post-war rebuilding efforts in the past. General MacArthur’s strategic rebuilding of Tokyo, Japan after WWII and the lessons learned from rebuilding Iraq provide useful models for moving forward. Incorporating modern 3D printing technology could greatly benefit Gaza’s reconstruction as well.

After WWII, General Douglas MacArthur took charge of overseeing the rebuilding of Tokyo. His strategic vision transformed the city into one of the most efficiently organized and clean urban centers in the world today. Rather than quick fixes to get things back up and running, MacArthur planned years into the future – implementing wide boulevards, underground railway systems, and decentralized industrial hubs. This long-term thinking allowed Tokyo to prosper in the decades after the war.

Rebuilding Gaza should adopt a similar forward-thinking mindset. Short-term band-aid solutions may temporarily patch infrastructure but fail to address growing future needs. Gaza’s population is very young, with a median age under 18 years old. Over 60% of Gazans have not yet reached adulthood. As these youth become adults in the coming decade, there will be increased strain on housing, hospitals, transportation, energy grids, and other civic services. Rebuilding efforts must factor in this rapidly growing and young demographic bulge.

Lessons can also be learned from the challenges faced in rebuilding post-war Iraq after Saddam Hussein’s regime was toppled. The Iraqi bureaucracy and government workers who kept the country functioning were inevitably removed from power. Yet they were the only ones with the knowledge and skills to operate Iraq’s infrastructure and governing institutions. The US military was forced to learn this hard lesson by trial and error. In hindsight, it would likely have been more productive to collaborate with the existing system rather than scrap it entirely. There are parallels when planning for Gaza’s future. Utilizing insights and experience from professionals already on the ground can help avoid some pitfalls of rebuilding from scratch. General David Petraeus has echoed those statements.

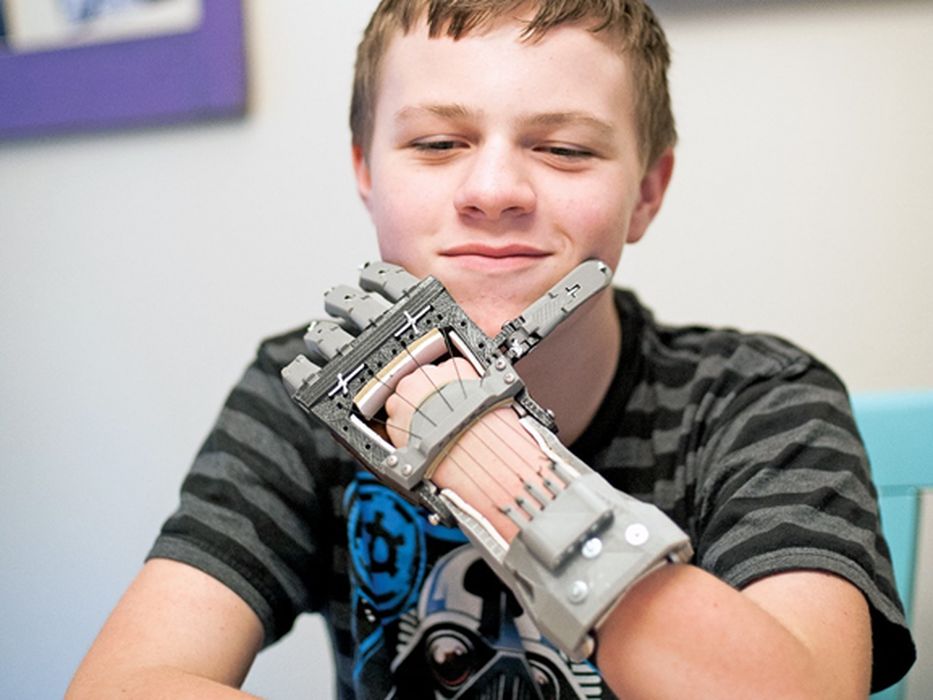

The two biggest infrastructure areas needing reconstruction in Gaza are healthcare and transportation/utilities. Delivering emergency medical care during active bombardment was difficult enough. Now, Gaza’s demolished hospitals must serve growing numbers in tragic circumstances – with sharply rising cases of amputated limbs. The challenge of supplying sufficient prosthetics and devices is compounded as children rapidly outgrow them and require new fittings.

Healthcare

3D printing offers innovative solutions that could greatly empower Gaza’s healthcare system. We have written previous Fabbaloo articles about the leading companies included in 3D printing prosthetics including 3D printing for medtech devices, orthopedics, and delayed elective surgeries. Some leading medical institutions, like the Mayo Clinic, utilize in-house 3D printers to supply prosthetics and medical devices tailored to individual patient needs. New York Hospital for Special Surgery outsources its 3D printing of prostheses to an on-site facility. The technology’s customizability, quick turnaround times, and cost-effectiveness make it ideal for Gaza’s crisis medical environment. Setting up local 3D printing labs in Gaza hospitals would allow limbs and devices to be printed on demand. Supply chains and overseas outsourcing delays could be drastically reduced.

Infrastructure

Alongside healthcare, rebuilding Gaza’s demolished infrastructure is critical for economic and social functions to return. Roads, bridges, power plants, and supply lines have all faced heavy bombardment. Again, 3D printing innovations could assist redevelopment plans. Emerging ‘3D printed buildings’ use giant cement printers to construct houses, office blocks, and infrastructure components. Early small-scale projects show promise, and the method will likely become mainstream in the coming years. Jumpstarting investment and R&D efforts for large-scale 3D cement printing in Gaza could allow for quicker redevelopment of destroyed sectors.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Gaza’s reconstruction is a chance for fresh innovative thinking anchored by lessons from history. Just as General MacArthur modernized Tokyo for the future, technology and foresight must play central roles for Gaza’s younger generations. By incorporating solutions like 3D printing alongside the expertise of professionals on location, rebuilding plans can avoid pitfalls and transform Gaza for a brighter tomorrow.