Charles R. Goulding and Preeti Sulibhavi look at six companies receiving grants for their contribution to industry.

“Connecticut is the Silicon Valley of advanced manufacturing, plain and simple,” Gov. Ned Lamont said in a statement when discussing the September 2021 grants six Connecticut-based companies received to adopt additive manufacturing or 3D printing into their operations.

The grants are administered under the Additive Manufacturing Adoption Program (AMAP). A program of the Connecticut Manufacturing Innovation Fund, AMAP is a partnership of the Connecticut state Department of Economic and Community Development (DECD) and the Connecticut Center for Advanced Technology, Inc (CCAT).

Under the Additive Manufacturing Adoption Program (AMAP), each company will receive a US$100,000 matching grant to be leveraged with an equal or greater amount of company funding. The grant recipients are:

- Burke Aerospace – Farmington

- Accurate Lock and Hardware Co., LLC – Stamford

- Beacon Industries, Inc. – Newington

- Okay Industries, Inc.- New Britain

- PTA Plastics – Oxford

- Westminster Tool, Inc. – Plainfield

This means that the Program is designed to incentivize at least US$1.2M in 3D printing purchases.

Additive manufacturing is rapidly changing the way companies design and manufacture products. Components that could not be produced just a few years ago can now be made to high standards using a wide variety of plastic, metals and other materials. When implemented properly, additive manufacturing can significantly reduce material waste, lead time, the amount of inventory being held, and the number of distinct parts needed for an assembly.

Below is some information about each of the companies awarded the grant.

Burke Aerospace (Turbine Technologies)

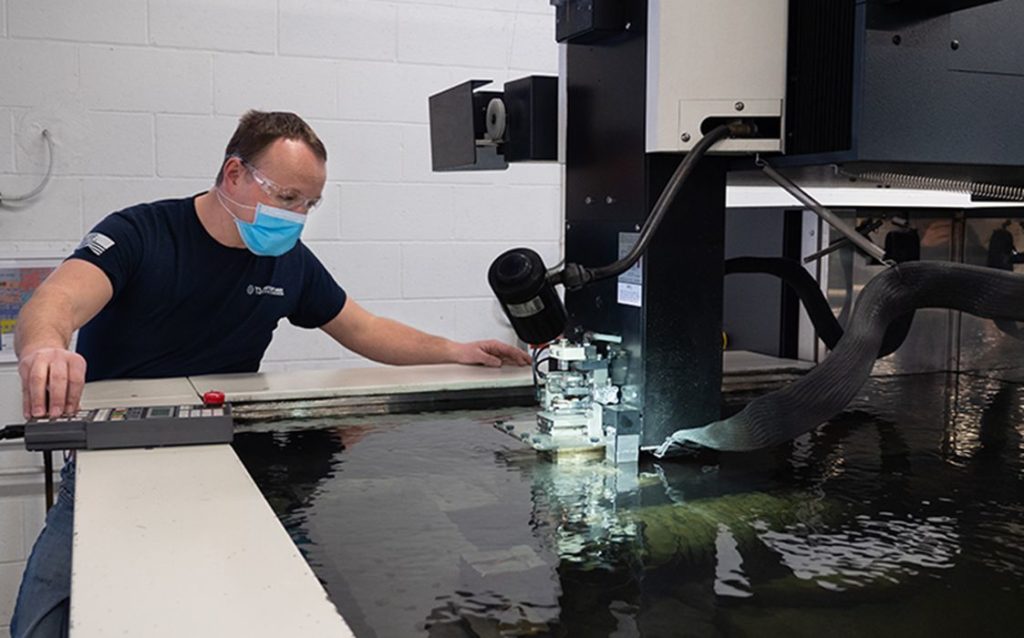

Turbine Technologies is a premier Aerospace and Industrial Gas Turbine component manufacturing company that has been in operation for over 50 years. Turbine Technologies is a privately held, high-tech manufacturing company supplying a variety of precision components and contracted engineering services to the Aerospace and Industrial Gas Turbine industries. Turbine Technologies products include CNC Sinker Electric Discharge Machining (EDM), Wire Electric Discharge Machining (WEDM), High Speed Hole (HSH), Airflow testing, and 5 Axis Milling services. Turbine Technologies provides all EDM and milling solutions for turbine blades/buckets, vanes/nozzles, shrouds, combustor components, engine cases, and ring segments. The company has earned wide recognition for high quality, responsiveness, and lean enterprise that adds value and satisfies customers.

Accurate Lock and Hardware Co.

For about half a century, Accurate Lock and Hardware has been committed to providing the finest American-made locks and hardware solutions. Lock and door manufacturing processes support numerous 3D printing applications. In fact, the pandemic has resulted in a variety of touchless door applications.

Beacon Industries

The Beacon Group is well known for being a world-class CNC turning and (5 axis) milling operation. Their products meet the most rigorous and exacting standards of the aerospace industry. Because of the nature of their products, their equipment is of the highest standards and quality. This grant will only complement its existing arsenal of equipment.

Okay Industries, Inc

Okay is a leading medical device component manufacturer. Okay has considerable expertise in titanium applications, and in fact they are specialized in the use of titanium as a material for their products. Titanium is thus widely used for implants, surgical devices and pacemaker cases. Its use for hip replacements and other joints has been well established for some 40 years. Titanium not only fosters Osseointegration (joins with bones & tissues), but it is also non-magnetic and non-radio opaque, and therefore is the most bio-compatible of all metals due to its corrosion resistance, strength and low modulus. Okay is a leader in the use of titanium in its medical device component manufacturing processes. Medical implants that titanium is often optimal for include hip and shoulder surgeries, as our firm’s biomedical engineers have written about in previous Fabbaloo articles.

PTA Plastics

PTA Plastics (PTA) is an Employee-Owned plastic injection molding company founded in 1953 with the vision to bridge the gap between product design and production. PTA focuses on the medical industry, defense/security industries and emerging technologies. They also offer engineering support by performing full Design for Manufacturing (DFM) on all awarded projects (trained engineers perform 3D mold filling analysis on each part prior to design).

Westminster Tool Inc

Westminster Tool is a leader in manufacturing injection mold systems. Their enhanced service offerings include pre and post-manufacturing services.

The company has a versatile technical design team that consists of plastic, mechanical, tooling, and aerospace engineers. Whether their customer requires a complete mold design, design for manufacturing, material selection, or reverse engineering services their experienced design team is able to support our customers’ unique challenges.

Westminster Tool’s capabilities include:

- Lean Process Development

- Automation Utilization

- Palletization

- Unattended Production

- High Speed Machining Holding Tolerances of +/-25 Microns

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies and startups developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Congratulations to the six Connecticut companies awarded the AMAP grant. This added resource can fuel further innovation in the additive manufacturing industry and bring the technology to production even faster.