Sygnis has participated in a breakthrough energy project with a new ceramic 3D printing solution.

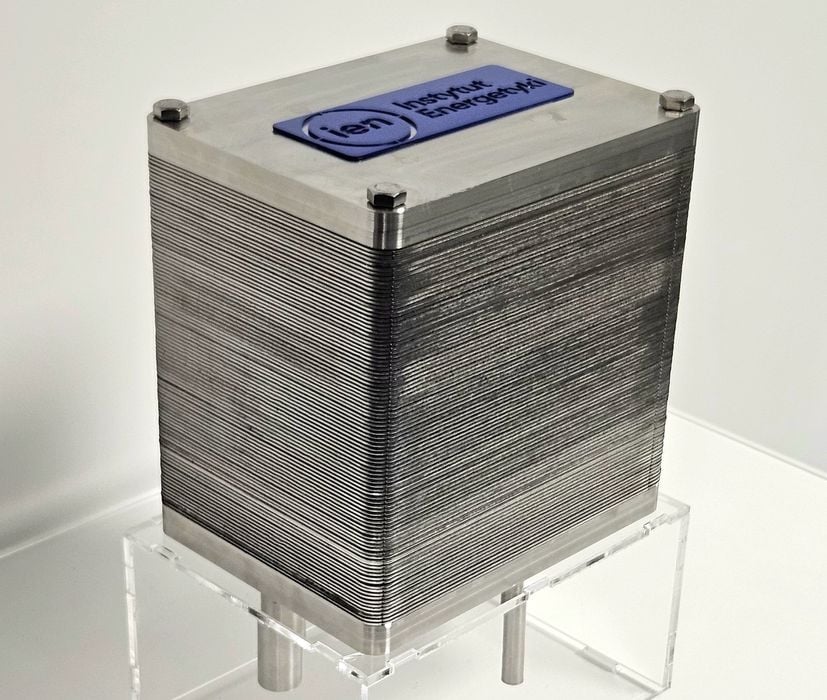

The company worked with the Polish Institute of Power Engineering to create a prototype hydrogen generating system called “HYDROGIN”.

Hydrogen is one of the fuels of our renewable future. Unlike oil, which you simply dig out of the ground and use, hydrogen must be produced using an energy-intensive process such as electrolysis. Once made, the hydrogen can be stored and used later, much like current fossil fuels. However, when it burns it releases only water vapor, which doesn’t particularly affect the environment.

That may sound quite suitable, but the issue is in how much energy is used to produce the hydrogen. Too much and it’s not efficient.

The HYDROGIN design attempts to overcome this barrier by using a new technology called “reverse solid oxide cells” (rSOC). This tech allows for very high efficiency, said to be more than 92%. That means that if 100 units of electricity are applied to the cell, then it produces an amount of hydrogen that offers 92 units of energy. That’s pretty efficient, I’d say.

One very important potential application for this technology could be to capture energy from surplus renewable sources. For example, when wind turbines generate more power than is required, it’s normally lost. But with HYDROGIN one could use the extra energy to generate hydrogen for later use. Thus the energy effectiveness of this system is actually much greater.

The HYDROGIN cells can also act as fuel cells, generating electricity on demand, making them even more versatile.

Sygnis was involved in the project to 3D print complex ceramic seals on the layers of the cells. Additive approaches were desired because the cell geometry can change per application, and thus a way to make different types of seals was required.

Sygnis explained how this took place:

“The seals developed at the Institute of Power Engineering were made using an innovative method of 3D printing from ceramic paste using machines designed and manufactured by Sygnis S.A. specifically for this purpose. The use of additive manufacturing makes it possible to form a sealing material from glass paste with appropriate rheological properties directly on the flat and corrugated surfaces of elements of rSOC stack. It also makes it possible to create multilayer seals, thus allowing to optimize their thickness depending on the application and, as a result, to increase the efficiency of the process and maintain its high repeatability.”

No doubt this project leveraged the company’s experience in glass 3D printing, which we’ve covered previously.

I’m pleased to see 3D printing help create the breakthroughs required to address the climate emergency. This is one more step forward.

Via DirectInkWriting