Charles R. Goulding and Preeti Sulibhavi consider the use of 3D printing technology to expand smallsat applications.

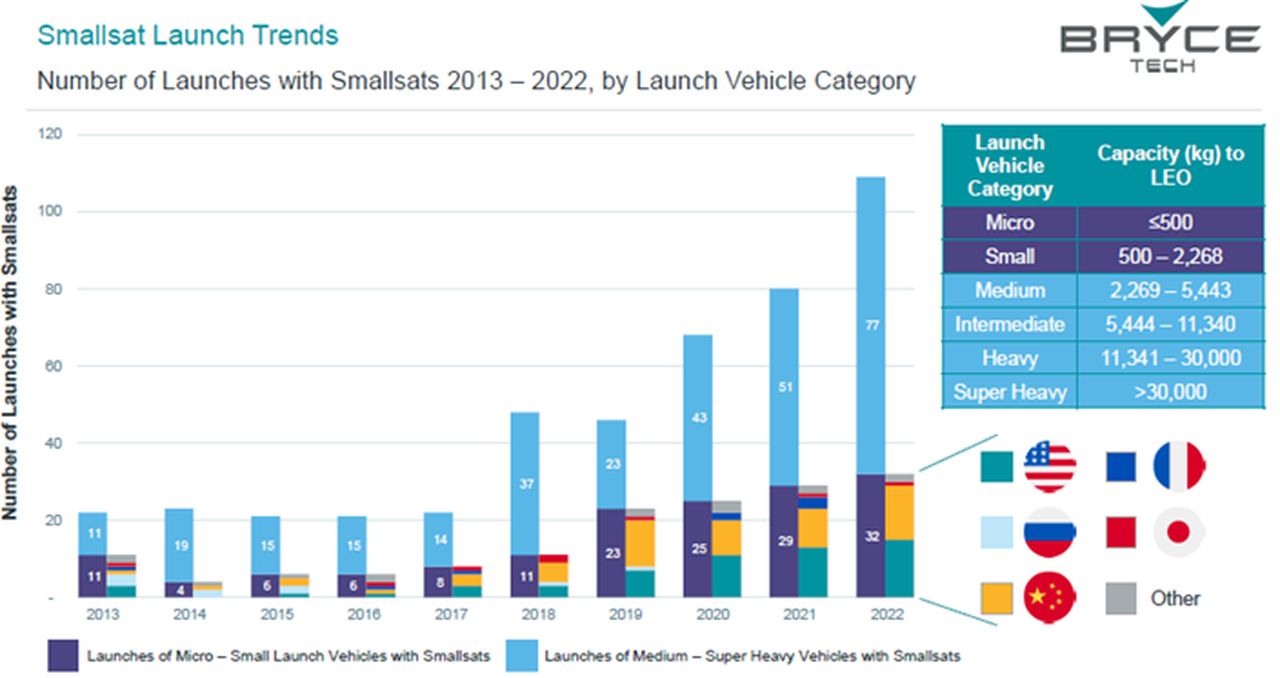

In recent years there has been a record number of “smallsat,” or small satellite launches. According to the 2023, 35-page Bryce “Smallsats by the Numbers 2023” report, small satellites have broken records and are transforming in-space architectures. The year 2022, marked a year of record 2,304 launches with the biggest user being SpaceX ‒ no surprise there.

We have written about space startups and how 3D printing can impact the industry on Fabbaloo before. However, now we are focusing on the quest for achieving a smaller footprint with more precise and compact payloads.

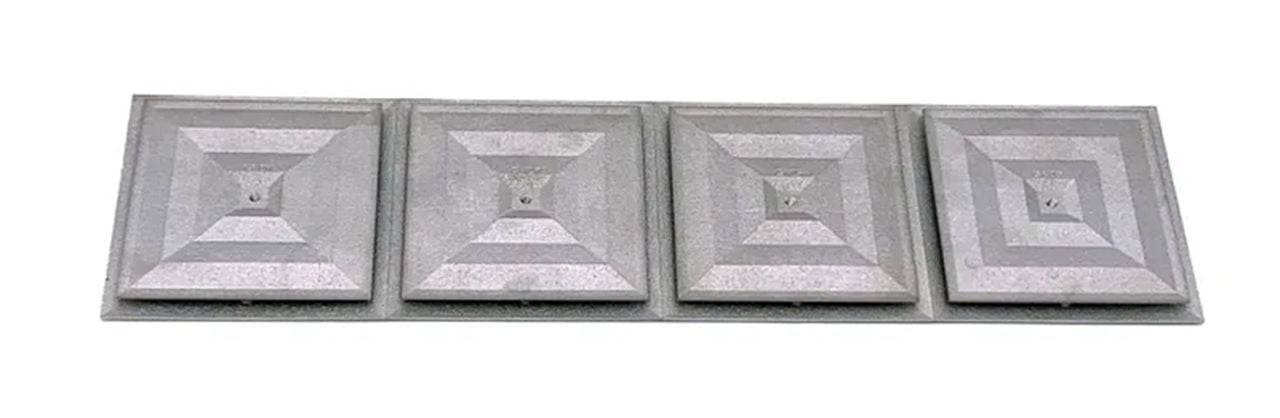

Each year satellite weight is decreasing and 3D printing is ideal to create high quality, lighter-weight satellite components.

Smallsats can provide targeted services in specific areas. Satellite makers are increasingly integrating 3D printing technology because it can accelerate production while improving efficiency in a cost-effective manner.

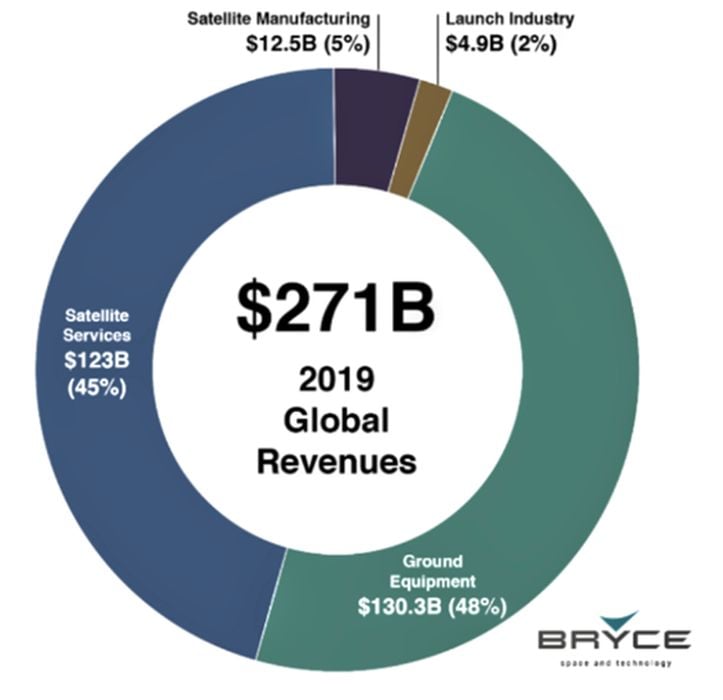

The Satellite Industry Association (SIA) released its 23rd annual study of satellite industry performance, providing an in-depth analysis of 2019 activity. The information was derived primarily from proprietary surveys, information available to the general public and Bryce’s own independent analysis. Some of the results are illustrated above.

3D Printing and Smallsats

Fabricating smallsats, whether they are minisatellites, microsatellites, or nanosatellites, the dimensions and specifications required of these space vehicles is amenable to the capabilities of 3D printers, particularly because the technology can produce highly complex parts that meet specifications, yet are lightweight.

In fact, Boeing and Millennium Space Systems have brought together Boeing’s production expertise, domain knowledge and manufacturing capabilities with Millennium’s flexible and high-speed prototyping technology to create expedited delivery times for smallsats.

Intelsat 45 (IS-45) will be based on 3D printing specialist, Swissto12’s HummingSat satellite platform, which at about the size of a dishwasher is one-tenth the size of conventional GEO satellites.

At just one cubic meter in volume, Swissto12 CEO Emile de Rijk said HummingSats are “at least 3 times cheaper” than larger telecoms commercial satellites in GEO, with the same coverage area as traditional spacecraft in GEO.

We have previously covered the use of additive manufacturing in space, where 3D printers are actually sent into space with payloads to repair or even fabricate vehicle parts. Due to the unique properties of the space environment, specifically microgravity it is theoretically possible to implement new 3D printing processes. For example, a satellite could potentially be built from the inside out, where the first material depositions are at the part’s center and expand outward while rotating. Whereas in Earth’s gravity, 3D printing processes mostly layer material on top.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

While the US continues to lead the smallsat industry in launch activity, rideshare opportunities and targeted missions, there is no end to the opportunities the 3D printing industry has in terms of prototyping and producing replacement parts for various micro and medium-sized launch vehicles and satellites. 3D printing can help us reach the “next frontier.”