Charles Goulding, Jr. considers how 3D printing might help the U.S. both compete and cooperate with Chinese manufacturing.

Facing the Future

To the surprise of some pundits, President Biden has been hawkish on China, from both a political and economic standpoint. Politically, Biden took the unprecedented step of inviting a member of the Taiwanese government to a presidential inauguration – quite a signal given China’s refusal to recognize an independent Taiwan. Through high-level appointees, Biden has also been critical, in the early stages of his presidency, of China’s internment of Uighurs.

Economically, Biden places China center stage in his Build Back Better plan, noting in the first paragraph of a recent press release that,

“The American Jobs Plan is an investment in America that will create millions of good jobs, rebuild our country’s infrastructure, and position the United States to out-compete China.”

Manu in the Middle

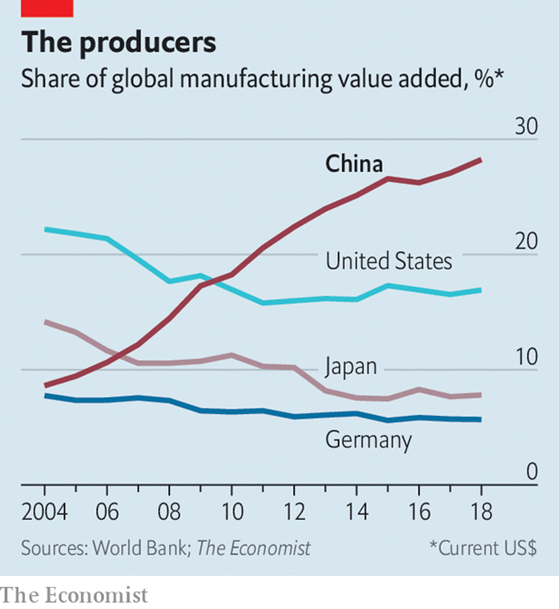

Caught in the middle of the competitive hubbub is manufacturing. For years, China has been firmly established as the “factory of the world,” leading not just in sheer output but in manufacturing valued-added (the difference between revenue and costs of inputs):

Climbing up the value chain requires innovation since innovative products often yield higher margins. That means that in the past fifteen years, China has made key strides in areas like product design and manufacturing efficiency.

To keep up, the United States will have to be strategic. Mere onshoring is not enough. Instead, the U.S will have to select industries and product lines that it can lead technologically, whether through advanced design, superior processes, or an integrated Industry 4.0 approach that streamlines production.

3D Printing as a Competitive Advantage

One source of competitive advantage for the U.S. and for other Western economies could be 3D printing. The U.S. has frequently been a design leader, from smartphones to medical equipment to precision instruments. Rapid prototyping and small-batch manufacturing with 3D printers can assist with design leadership for the most highly specialized products of tomorrow.

In some instances, 3D printing can play an even larger role in market differentiation. Indeed, as 3D printing has matured, it has been used for Industry 4.0 roles like application testing and end-use production.

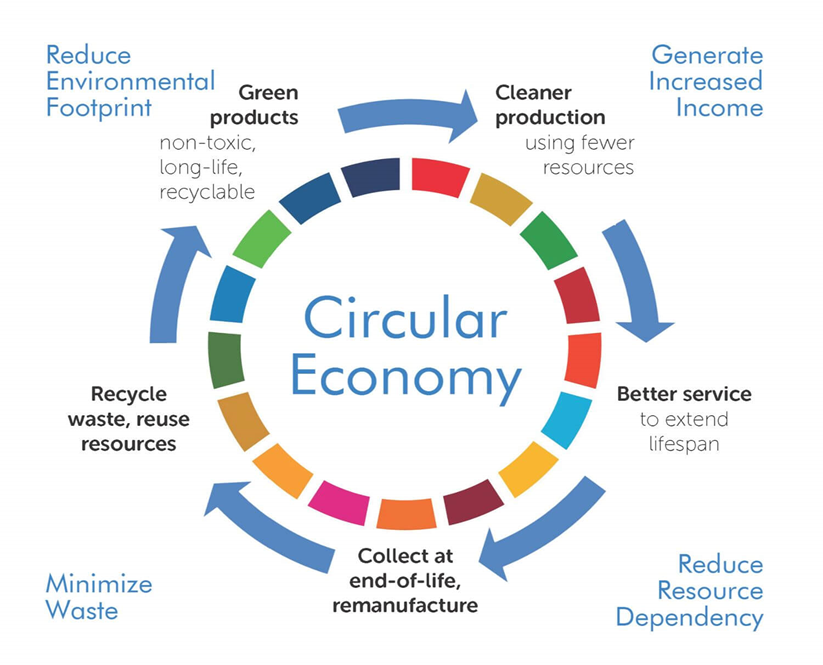

3D printing is also a frequent part of what’s now known as the “circular economy,” a view of production wherein materials are sustainably maintained in a circular loop. (By contrast, the more traditional “linear economy” starts with material extraction and ends with product disposal.)

The circular economy is a step forward for sustainability and for market competitiveness, particularly as those to objectives converge. Indeed, the approach is more efficient, and in increasing demand by governments and individual consumers alike.

For all these reasons, water and waste giant Veolia now supplies French startup Francofil with resins to produce 3D printing filaments. By supplying this steady flow of recycled plastic, Veolia fulfills part of its ecological mission to foster a profitable, sustainable economy.

Room for Cooperation

Not every problem is solved with cut-throat competition. Far from it: some of the most pressing global challenges result from market failures only fixable through unprecedented cooperation.

Both the U.S. and China appear to recognize this. Just this week, the two countries issued a joint statement pledging to fight the climate crisis “with the seriousness and urgency that it demands.”

Fighting climate change (and other global challenges, like water scarcity) will require leading countries to look past the short-term toward long-view approaches favoring collective progress.

In a host of other instances, further, bringing back production will be difficult if not impossible. To illustrate the point, the Harvard Business Review takes the case of ventilators. When the machines were at a premium during the early days of Covid-19, President Trump discussed onshoring all production. But for such an advanced item, component parts (like pressure sensors and valves in this instance) may still need to be globally sourced.

Given the intricate web of inputs and supply chains that make up modern production, there is no such thing as total economic isolation. Instead, countries benefit simultaneously when each offers novel inputs and ideas.

The China Challenge

If the U.S. and other Western countries are to continue as global leaders, they will have to evidence exceptional thinking and collaboration. To that end, President Biden has spoken a great deal about infrastructure and innovation in the early days of his presidency. Finding opportunities both to outcompete and to cooperate with China will be pivotal in achieving those goals.