Charles R. Goulding and Preeti Sulibhavi propose several ideas for leveraging 3D printing technology to solve today’s water crises.

The recent total water system failure in Jacksonville, Mississippi, a state capital city with 150,000 residents, is a wake-up call for US water providers across the nation.

The current US water system was largely put in place pursuant to the Clean Water Act of 1972, which was 50 years ago. The 145,000 public water treatment facilities are decaying. The US national system has reached the end of its useful life and needs an upgrade.

Every two minutes there is a crack in the country’s underground water system. When enacted in 1972, major goals were physical infrastructure improvements and the control of pollutants. The well-publicized Flint, Michigan 2014, water system contamination situation demonstrated the impact of water system contamination.

President Biden’s Infrastructure Bill allocated $55 billion to expand access to clean water. The 3D printing industry is now able to provide many of the systems’ upgraded components including, but not limited to pipes, pumps, valves, filters and concrete liners.

Pipes

Pipes are one item that can effectively be 3D printed with consistency. Drain waste pipes are usually plastic and can be 3D printed. 3D printers that use thermoplastic filaments can produce piping that is durable and able to be used as part of a building’s plumbing system. These pipes serve to carry waste down and away from the home and allow the sewer gases to be pushed out through the roof. This will avoid flooding and create a problem like the one in Mississippi.

Pumps

Pumps are an important tool in manufacturing processes as well as for executing civil engineering designs. Pumps can be 3D printed, especially for prototype parts or replacement parts. Needless to say, pumps play an important role in keeping water in places where they can be of great benefit to society as opposed to places where they can harm communities.

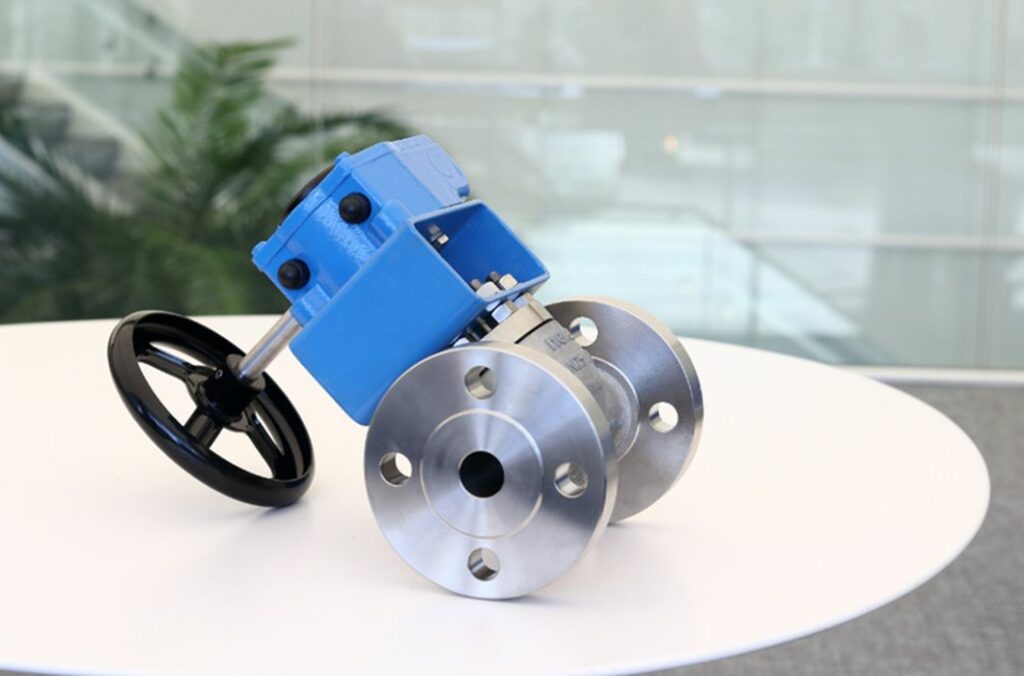

Valves

Valves control the flow of water to where it should be going. There have been recent groundbreaking improvements to 3D printing valves. 3D printing allows for complex geometries that traditional manufacturing methods cannot achieve. 3D printing also allows for the construction of integrated molding, ultimately producing products faster and at lower cost.

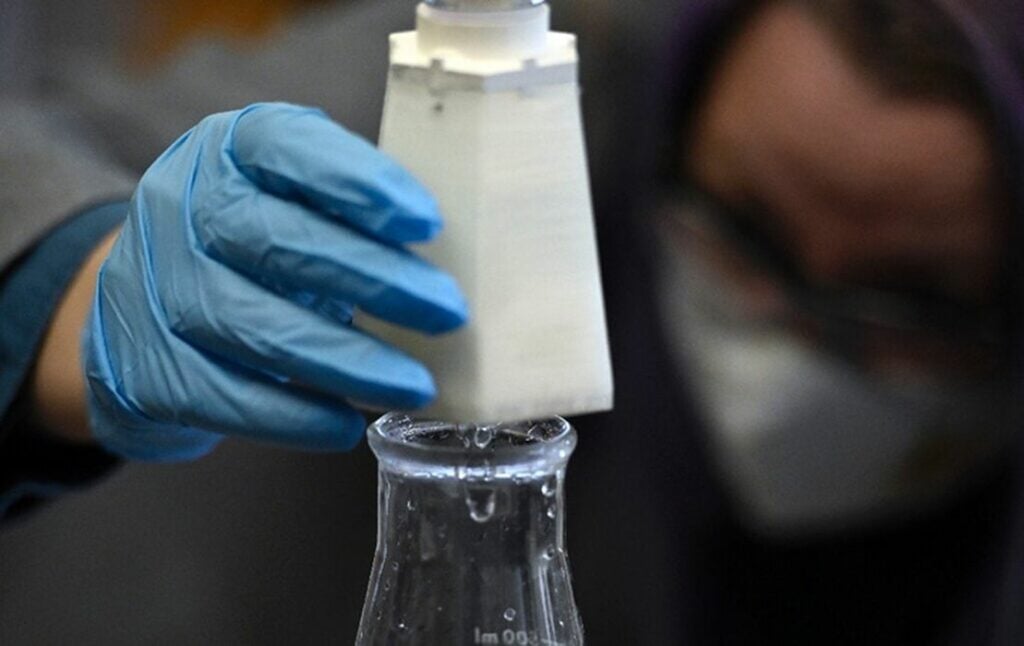

Filters

Filters are among the top items needed for water infrastructure. Whether it is reverse osmosis, fabricating the right membranes for filtration or producing an ultra-thin membrane for faster flowrate and less pollution, 3D printing offers benefits to all these met

Concrete

Concrete is a material that the 3D printing industry has been looking into very seriously over the past few years. Concrete liners can improve water storage and irrigation systems. 3D printed concrete robot/gantry units can be moved to challenging geographic locations and provide the required infrastructure.

Since we are dealing with a global water crisis, we can look to other countries for solutions. Dubai has integrated a more sustainable way for providing utilities, including water, to its residents and 3D printing has been a major part of this effort.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The solution for water infrastructure lies in how improvements are designed and developed. Utilizing 3D printing at the start can make the process much smoother and more effective.