Charles R. Goulding and Preeti Sulibhavi look at the use of 3D printing in five major healthcare companies.

The top five orthopedic medtech companies by sales are listed below:

- Stryker ‒ US$17.1B

- Johnson & Johnson – DePuy Synthes ‒ US$8.6B

- Zimmer Biomet ‒ US$6.8B

- Medtronic Technologies ‒ US$4.5B

- Smith & Nephew ‒ US$3.7B

All these companies utilize 3D printing, some more than others.

There are many ways 3D printing has impacted the medtech industry. We have covered how 3D printing helps with organ and body part development and the 3D printing potential at the University of Rochester (UR) Medicine Orthopedic Center. During the initial global Coronavirus pandemic, we covered how medtech is driving telemedicine.

We review major 3D printing developments at the top five medtech companies in this article.

Stryker

There are numerous examples of where Stryker has advanced the medtech industry with 3D printing. With 3D printing, Stryker can manufacture scaffolds that promote biologic fixation, which is the growth of bone into a prosthetic. This is key in recovering from ankle, hip, knee or shoulder replacement surgeries.

Johnson & Johnson – DePuy Synthes and 3D Printing

At J&J DePuy Synthes, 3D printing is being utilized for more than just replacement parts. It is being used to fabricate surgical instruments, surgical robots, and other operation room (OR) solutions.

This has countless medical applications for surgical processes as well as the implants being used for replacements.

Zimmer Biomet

Surgeons now have the option to 3D print patient-specific implants that can provide successful solutions to complex cases and improve patient health outcomes at the same time. Zimmer Biomet has also created AI-powered ORs for surgeons that are designed to streamline surgical workflows; everything from patient entry, door count, to the start and stop of anesthesia, surgery & cleaning up can become automated versus traditional manual tasks. This system is referred to as “Omni Suite” and it provides data points that have traditionally been captured manually, but because of AI capabilities, can now be streamlined automatically, leaving more time for patient care.

Medtronic and 3D Printing

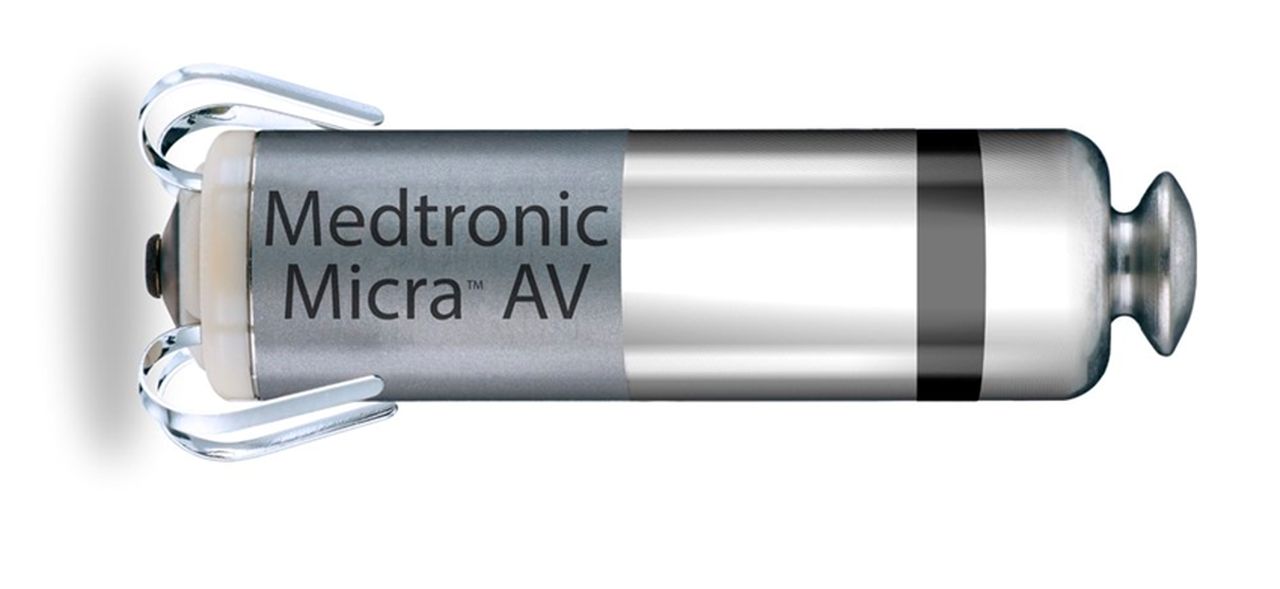

It is not only bone implants that companies are using 3D printing to replace. There are other devices that monitor the heart for instance (i.e., a pacemaker) that can be 3D printed. Medtronic’s Micra™ AV implant helps patients with AV block that did not respond successfully to traditional dual-chamber pacemakers by allowing the device to adjust pacing in the ventricle to coordinate with the atrium by the use of internal atrial sensing algorithms that detect cardiac movement.

Smith & Nephew

Smith & Nephew is using 3D printing to create complex structures based on digital models. This is having positive outcomes for numerous outpatient clinics that require patient-specific solutions and applications. 3D printing has been used in creating customized surgical equipment, implants, prosthesis, regenerating musculoskeletal tissue and bone, cartilage, tendons and ligaments.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The growth of the medtech market is not surprising, given the recent advances in materials and 3D print technology. How 3D printing positions itself in the next few years in this industry will have a lasting impact on healthcare for generations.