Charles R. Goulding and Arianna Coger examine the ways in which 3D printing for prosthetics may address the phenomenon of phantom limb pain.

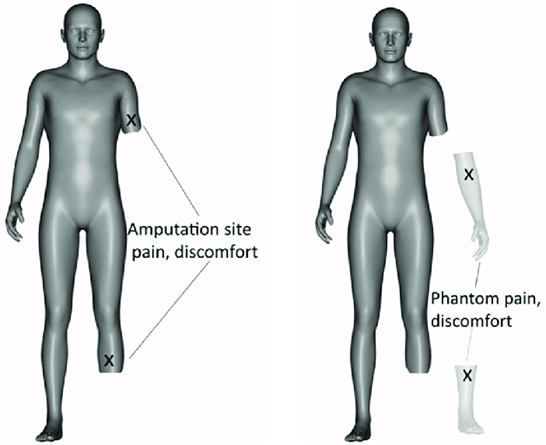

We recently had the pleasure of attending the Yale Club of New York City event entitled “Phantom Limb Pains and Prosthetic Narratives with Professor Alastair Minnis.” Alastair Minnis, a Professor Emeritus of English at Yale University, presented his research and thoughts on the phenomenon known as phantom limb pain. Often, individuals who have lost limbs may continue to feel sensations, ranging from pain to pleasure, at the amputated area. The idea of phantom limb pain was first described by Ambroise Paré, a French surgeon during the 1500s, who had observed the phenomenon occurring with several of his patients. The term itself was later coined by Silas Weir Mitchell, a US Civil War surgeon who wrote a short story describing the sensation.

For centuries, phantom limb pain was considered a psychosomatic phenomenon only caused by stress or anxiety. Men had often concealed their phantom pains due to fear of ridicule or ostracization. As a result, very few of them received any form of treatment. Women who visited doctors regarding phantom pains were often believed to be plagued with hysteria and dismissed.

The idea of treating phantom limb pain has only recently become a serious prospect. Medical practitioners are now acknowledging the brain’s role in the creation of phantom limb sensations. Neurologists have theorized that the cause of phantom limb pain is related to how the somatosensory complex within the brain maps parts of the body. Parts of the brain near the areas that had mapped to the missing limb can send signals that contribute to the occurrence of phantom limb sensations. Further research has shown that the mechanism is more complex, with distant areas also influencing phantom limb sensations.

Phantom limb pains have become more widely recorded from 1980 onwards. During the ‘80s, patients were often prescribed painkillers as a treatment for phantom limb pains. This, however, was not always very effective. As interest in the topic has grown, more scientists have begun researching alternative treatments. Due to improvements in technology, prosthetics are becoming more viable as a potential treatment for phantom limb pains and sensations.

Prosthetics and 3D Printing

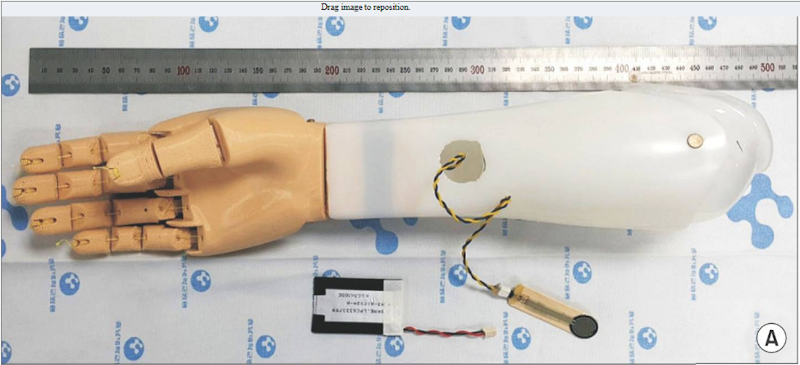

Prosthetics can be used to help alleviate phantom limb pain. Prosthetics can have direct contact with the amputation site, stimulating blood flow. Myoelectric prosthetics include electronic sensors along with residual limb musculature that detect nerve, muscle, and EMG activity. This nervous system activity can then be translated to electronic motors to control the movement of artificial limbs. Controlling the movement of prosthetics uses the same brain resources that once controlled the anatomical limb. This treatment can help prevent nerve overstimulation that may lead to phantom limb sensations. Poorly designed or ill-fitting prosthetics, however, can increase discomfort and pain.

Currently, custom prosthetics can be incredibly expensive and unattainable. 3D printing can be used to significantly reduce the cost, time, and difficulty of manufacturing comfortably fitting prosthetics. 3D scanning technology can help design prosthetics that accurately mimic the shape of limbs for the characteristics of individual patients. A combination of electrical engineering, biomedical engineering, and 3D printing can improve the quality of prosthetics and the quality of life for those with missing limbs.

More companies are beginning to combine the fields of medicine and 3D printing. 3D printing has been utilized by the medical industry for a variety of medical devices including teeth aligners, surgical models, skull caps, and spinal implants. Prosthetics can be added to this list. Further research and advancement of prosthetic technology is sure to come in the future.

Federal tax incentives, such as the Research and Development (R&D) Tax Credit, are available for companies that engage in 3D printing activities.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Final Thoughts

As prosthetic designs continue to improve and resemble human body parts more closely, the potential to mitigate phantom limb pains increases. Perhaps sometime in the future, researchers will be able to combine the technology for 3D printing organs and 3D printing prosthetics to develop realistic, fully functioning artificial limbs.