An Australian startup seems to have found a way to significantly speed up DLP 3D printing.

We suspected others have been working on dramatic improvements to 3D printing processes after the Carbon3D story came out and it’s true: Gizmo 3D Printers has an alternate fast printing solution.

Like Carbon3D, Gizmo 3D Printers’ process involves UV-curable resin. Unlike Carbon3D, Gizmo 3D Printers uses a “top down” printing technique instead of a “bottom up”.

Whereas Carbon3D (and many other vendors) shine the UV light through the bottom of a clear resin-filled tank, building from the bottom, Gizmo 3D Printers prints on top. Their DLP light shines from above onto the perfectly flat liquid resin surface. A build plate is stationed just barely below the surface of the resin. It lowers to produce additional layers as the UV curing continues.

This top-down approach has previously been used in many 3D printing operations, most particularly in large stereolithography machines. In these machines, the completed print dramatically rises out of the resin tank in seconds when done – even though the print may have taken hours.

But what’s so different about Gizmo 3D Printers’ approach? They use a “continuous curing” process. Other top-down printers use a layered approach, where a layer is fused, then the plate lowers to permit resin to cover the plate. The printer waits for resin to flood in over the previous layer before UV curing occurs. There’s a few delays in this process, mostly due to resin flow effects.

However, Gizmo 3D Printers’ process moves the plate down only one layer at a time, not extra deep “dipping” for resin flow as is done in other machines. This permits UV curing to take place at a faster rate. They say:

I tried something new. I didn’t dip extra distance at all. I just let the print go. This meant I could speed up the process, because the dip time took around 15 seconds when dipping slow. I dipped at a slow rate so that the fluid didn’t get shaken too much. I was able to reduce the total layer time from 20 seconds to 5 seconds and it can probably go even faster than that. No dipping does reduce the quality of the print, but you can get a lot of speed from the printer. So you can decide between speed and quality really.

This poses an interesting question: Could you use a resin process to produce quick, lower-resolution prints instead of resin printing’s typical use case: ultra-high resolution prints?

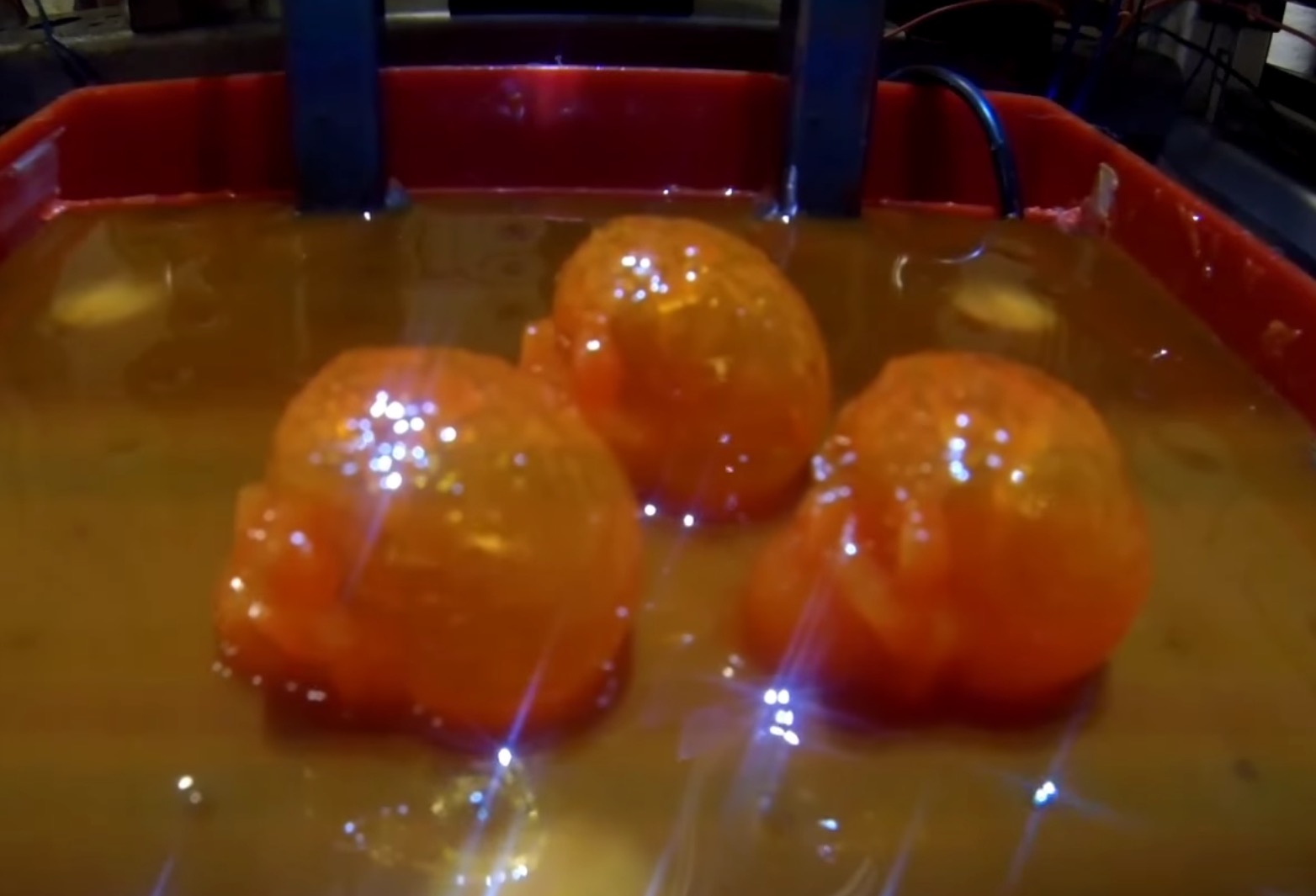

Gizmo 3D Printers thinks so. In fact, by tuning their discovery, they’ve been able to print pretty high quality prints (0.050mm layers) at a rapid pace. Check out this video where they demonstrate, in real time, printing some objects in only six minutes!

There’s obviously some restrictions, such as orienting the part so that resin can always easily flow – and it may be that certain geometries are impossible to print. However, the company continues to develop their new approach and may eventually end up as a product you could purchase.

Gizmo 3D Printers’ work reinforces our belief that the technology of 3D printing is STILL just at the beginning. There are many discoveries yet to be made, some of which could change our world a great deal.