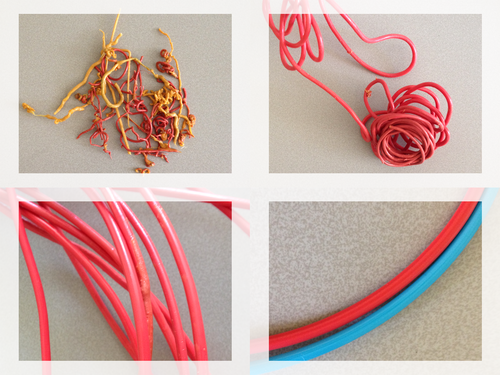

3D Hubs has been doing some experiments with their Filabot to prepare their own printer filament.

The idea is that you can either recycle plastic from failed prints or purchase cheap bulk plastic pellets to save cash on your materials needs. Feed those into a filament maker such as the Filabot and hopefully you’ll make useable filament.

But as 3D Hubs found, it’s not quite that easy. Most filament-based personal 3D printers are quite particular about the quality of the filament. While the chemistry of the plastic may affect its temperature sensitivity, more serious problems can be caused by variations in the filament diameter.

There’s a reason most filament suppliers these days quote their filament diameter tolerance. Take for example this shot of the specifications for White PLA Filament from Cheap3DFilaments. It tells us a lot about their filament’s quality: 1.75mm filament is always within 0.10mm, so expect filament between 1.65 and 1.85mm. This filament also is expected to maintain its round cross section to within 0.07mm.

The GCODE instructions sent to your personal 3D printer that are used to build the object do not know anything about the filament quality. It assumes there is a consistent supply of filament entering the extruder.

This is where the problem occurs – if the filament happens to be too large (as in, say 1.95mm in the above example), then suddenly the hot end has a lot more plastic to deal with. The pressure from the extruder means you have more plastic shooting out the nozzle than originally intended. This could create blobs, for example. The inverse situation is also possible: should the diameter be less than expected the extrusion becomes sparse.

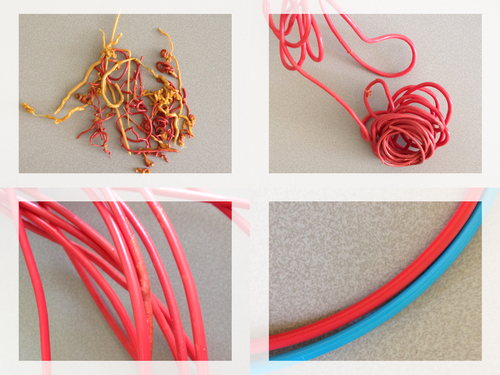

The worst scenario is the one 3D Hubs encountered with their experiment: the filament diameter was too large and excess liquid plastic somehow squirted UP the hot end until it encountered a cool area where it suddenly solidified. They described their unfortunate situation:

Our nightmare became reality. The nozzle clogged mid-print, although the temperature was set on 240 Cº. We think it had to do with the variation in diameter. What followed were countless hours of poking needles and thin metal threads in the nozzle, and even molesting it with a creme brulée torch. It’s no fun having to hurt your baby like that.

For now, we’d avoid self-made filament unless you can truly ensure the filament is completely compatible with your device.

Via 3D Hubs