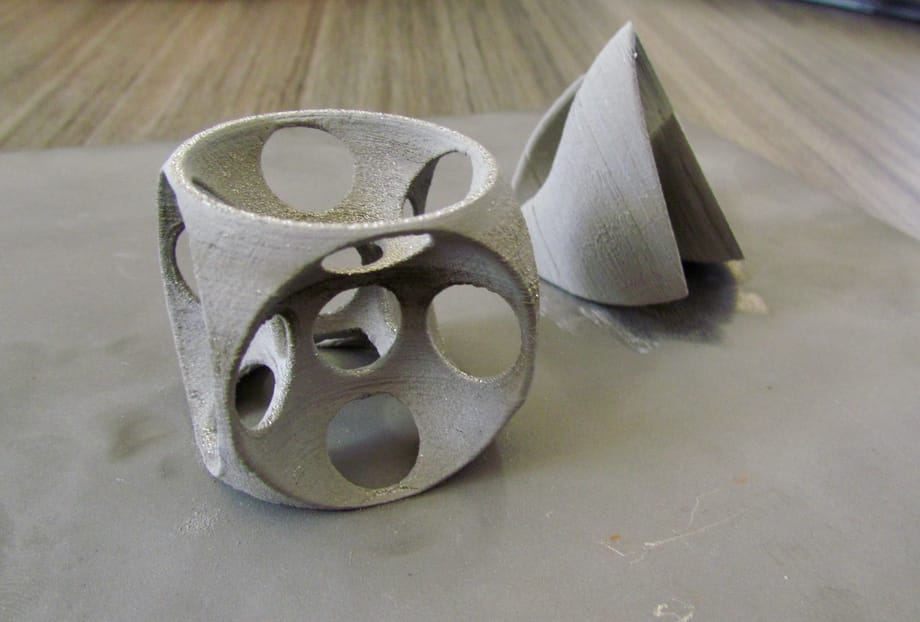

We had an in-person look at Aurora Labs’ new 3D metal printer, and found it to include a very interesting feature.

Aurora Labs is an Australian startup focused on developing 3D metal printing technology and so far they seem to be succeeding. They are only three years old, but in that time they’ve not only raised significant funding (multiple USD$1M+ rounds), but also have executed an initial public offering (IPO), something very very 3D printer manufacturers have done, let alone a smaller one.

They develop “medium and large” 3D metal printing equipment that employ powder and lasers to solidify metal objects.

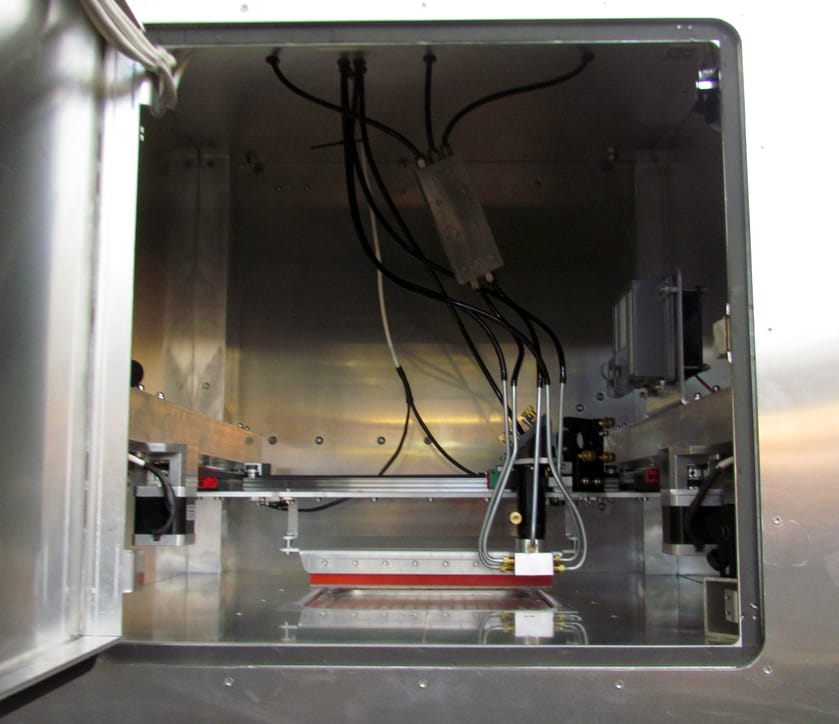

The powder is fed from the top and is placed on a flat bed where two lasers are employed. The lasers can be ganged together by focusing on a single spot in the argon-filled build chamber to effectively double the power. In this way they can use lower cost, lower power lasers to great effect.

The small system shown at top will eventually be joined with a “pro” model that will be a “completely different system”. They say it will involve print speeds of up to 100X faster. But that will be a story for another day.

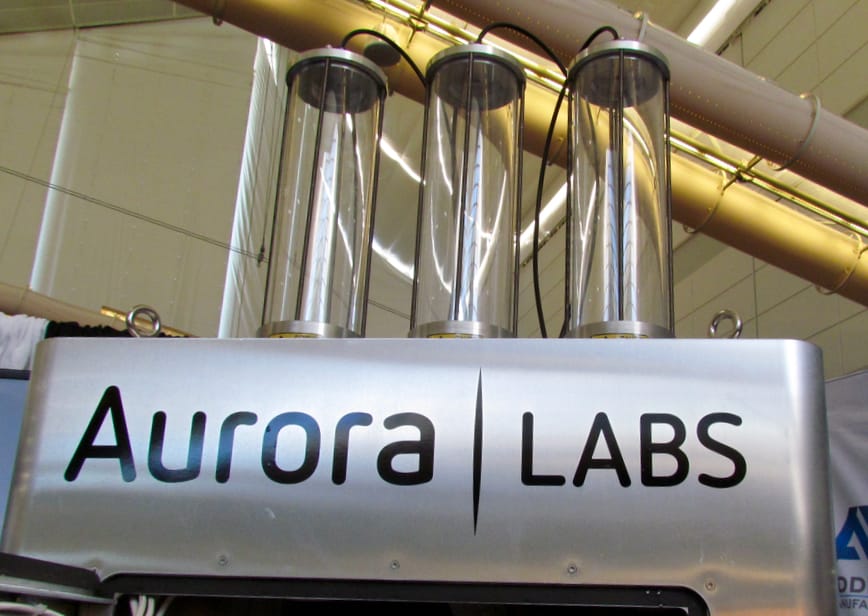

But what I find most intriguing about this system are those three powder hoppers on the top of the machine.

Into these three can be loaded the metal powder to be used in the print – but they don’t have to be the same material! The recoating system can mix them on the fly to present a mix of material powders for lasering.

In other words, this machine can apparently create alloys – on the fly! And not of just two materials, as there are three hoppers, so three-way alloys are possible.

When asked, we were told the machine could actually change this mix layer by layer if required.

This capability seems very interesting and I cannot imagine the applications that might be possible if you have a part that, say, gradually changes alloy throughout its form.

It goes without saying that the machine offers “open materials” capability, making the alloy function even more interesting.

So far the company has sold around 30 units of the small format machine to primarily universities, at a price of around USD$50K.

That’s clearly a good price for a 3D metal printer, even a small one.

Via Aurora Labs