![Could a newly invented self-repairing material be used in 3D printing? [Source: Advanced Materials]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4ac052ce.jpg)

New research from MIT shows a potential approach for producing self-repairing 3D prints.

The research was not specifically regarding 3D printing, but rather involved the development of a unique material that is incredibly able to repair itself merely by exposure to air.

The theory behind the approach is based in biology: many plants and other organisms can self-repair. Their method is in most cases to transform carbon dioxide from the atmosphere into structural carbon to reinforce the organism’s body.

Can this be done with artificial materials? Yes and no, it turns out.

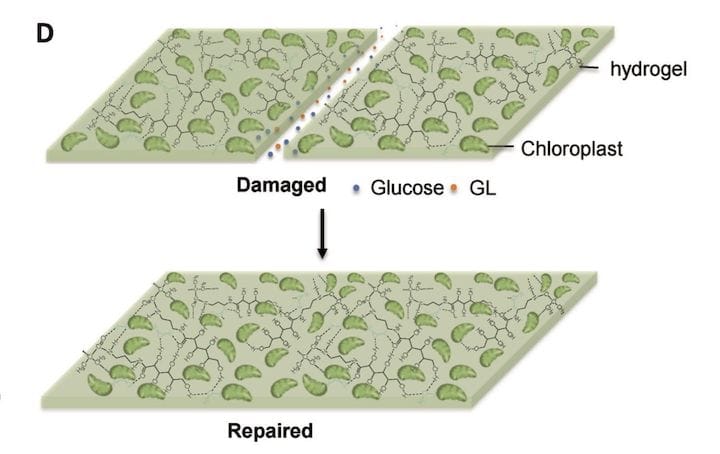

The researchers identified a biological component known as a “chloroplast”, which is a specialized component in plant cells that contains chlorophyll. It’s used by plants to convert sunlight and atmospheric carbon dioxide into organic molecules used by the plant. Could this same component be used in artificial materials?

Apparently so. Normally the lifeless chloroplast can continue to function for a short while after removal from a living plant cell, but the researchers developed a method of dramatically extending its use cycle, making their work practical.

They then mixed the hopped-up chloroplasts with a polymer material specifically designed to work with the output of the chloroplasts to produce additional structural material from the carbon. In other words, this material essentially hardened after exposure to the environment.

Hey, doesn’t that sound familiar? Hardening material is the fundamental core of many 3D printing processes. Could this substance be used in a 3D printing system?

From my reading it appears that the material is like a gel, meaning it could likely be extruded in a manner similar to how thermoplastic filament is extruded on many 3D printers. However, no heat would be involved as the material would already be soft.

The material would remain soft before extrusion so long as it would be stored securely from air and light.

But once extruded and exposed to the environment, the embedded chloroplasts would begin their natural work and gradually strengthen the printed object by adding carbon.

And thus you’d have a 3D printed object.

Would it be self-repairing? Perhaps. This is because of the limited active lifecycle of the embedded chloroplasts. After they deactivate there would be no additional carbon added. However, it may be possible for the researchers to further tune their chloroplast modifications to allow longer repair cycles. I’m also unsure how effective a repair could be as the solidified object may prevent movement of molecules within the structure.

Obviously this is an extremely rudimentary process at this early stage, but often processes are advanced significantly after their invention, and that might be the case here. For now, the researchers suggest that the strength of the material is practical only for use as a crack filler, for example, rather than a whole “standalone” object.

If self-repairing 3D prints could be achieved, there may be several radically new uses, as well as the obvious benefit of objects being able to close up punctures or breaks.

But self-repairing would initially be limited to sealing surfaces that are adjacent. A self-repairing object would not, for example, be able to re-grow an appendage that had been cut off.

That will have to wait for a much more sophisticated approach.

Via MIT

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.