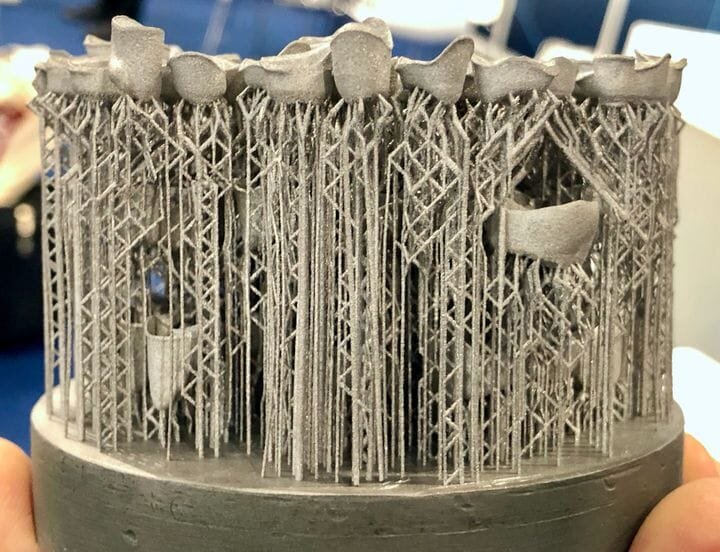

![A highly complex and optimized metal 3D print prepared by Oqton [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/oqton-complex-print-1_img_5eb08cad08343.jpg)

Oqton is a little-known startup in additive manufacturing that provides a series of services that no other company seems to offer.

The San Francisco-based company, founded in only 2017, hopes to apply AI-based techniques to the increasingly complex problems of managing additive manufacturing operations. They say that the majority of problems are due to process, not people, and they aim to supercharge those processes.

Oqton Cloud Services

What does this mean, exactly? It seems that Oqton offers a variety of cloud-based services that directly apply to additive manufacturing operations. Their product, FactoryOS, is said to be an “AI-Powered Production System for intelligent factories”. Here’s a short list of some of their services:

-

Extendable Cloud Platform

-

Directly Integrates With Production Systems Through Iiot For Real Time Activities

-

Quoting & Pricing

-

Inspection And Identification Services

-

Topology Optimization

-

Layered Nesting Job Setup

-

Autonomous Robotic Wire Additive Manufacturing

-

Autonomous Robotic Support Removal

-

Automated Hybrid CNC / Additive Manufacturing Workflows

-

And More.

Oqton AI Database

The key to FactoryOS seems to be a massive database that integrates essentially all data related to the manufacturing process. From this data Oqton can leverage machine learning techniques to automate various functions, as well as provide real time, historical or traceability analyses. They say they’re trying to “close the air gap between hardware and software”.

The concept should allow for an end-to-end solution that seems to pop up at all points in the additive manufacturing workflow. This may be an entirely new category of software solution for the industry.

Oqton Inspection Station Example

![Oqton’s prototype automated inspection station [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/oqton-inspection-station-1_img_5eb08cad51829.jpg)

Here’s an example of how this cloud-based AI system can manifest itself as a real-life automation solution. Oqton has devised a prototype of a quality control inspection station to accompany a 3D printer, seen here:

The inspection station works in a ridiculously simple manner: A completed print is tossed (literally) into the chamber. The operator then presses a button, and FactoryOS takes over.

-

The object is rotated within the chamber

-

A structured light scanner captures several views of the part

-

A rough 3D model of the object is created from the scan

-

The rough 3D model is matched against the database of known parts

-

If a match is found, then the dimensions of the part are compared against the desired 3D model’s dimensions from the library

-

If the part is within tolerance, a green light is shown

-

If the part is out of tolerance, a red light is shown

That’s it. Look at this device from the operator’s point of view: Remove the part, toss it into the inspection station, press a button. Throw away the part if you get a red light, keep it if green.

Brilliantly simple.

![Structured light 3D scan underway in Oqton’s prototype inspection station [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08cad90a26.jpg)

All of this simplification is due to the highly sophisticated AI algorithms and data in Oqton’s cloud. It’s amazing what software can do if supplied with the right data.

What’s particularly scary is that this inspection station was designed and implemented very quickly because most of the “smarts” were already in Oqton’s cloud, ready to be used.

Advanced Metal 3D Printing

The inspection station is only one manifestation of the power of Oqton’s cloud, and they have many more. Here’s another I had never imagined; take a close look at this metal 3D print:

![Incredible three-layer metal 3D print prepared by Oqton [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08cade4363.jpg)

You’ll notice that there are actually THREE layers of part embedded in this complex print job. The top layer is full of what appears to be teeth, but there are additional teeth in two layers buried in the print. The support structures for parts above “grow around” the lower-level parts. This allows for far more efficient 3D print jobs and can make more full use of the larger build chambers on some metal 3D printers.

And yes, there’s even more that I won’t describe, such as their digital foam generation tool, or their topology optimization feature, or their ability to record all statistics for each layer of a print. You get the idea.

Oqton Workflow Optimization

At this stage, Oqton has around 56 staff located in four offices worldwide. They’ve begun accepting clients wishing to optimize their additive manufacturing operations in various ways. Oqton’s services could be of tremendous interest to 3D print services, as the game there is to be as efficient as possible, something Oqton seems to be automating.

If you operate an additive manufacturing service, you should talk to Oqton.

Via Oqton