![[Image: EOS]](https://fabbaloo.com/wp-content/uploads/2020/05/EOS_Building_Process_Metal_EOS_Logo_Download1_img_5eb098ccc3d0a.jpg)

This week, EOS celebrates its 30th anniversary. EOS North America President Glynn Fletcher offers a look into operations and a look ahead in industry.

“It seems like a long time, but in the grand scheme of things it’s hardly a heartbeat,” he told me as we began a chat reflecting back on the last 30 years.

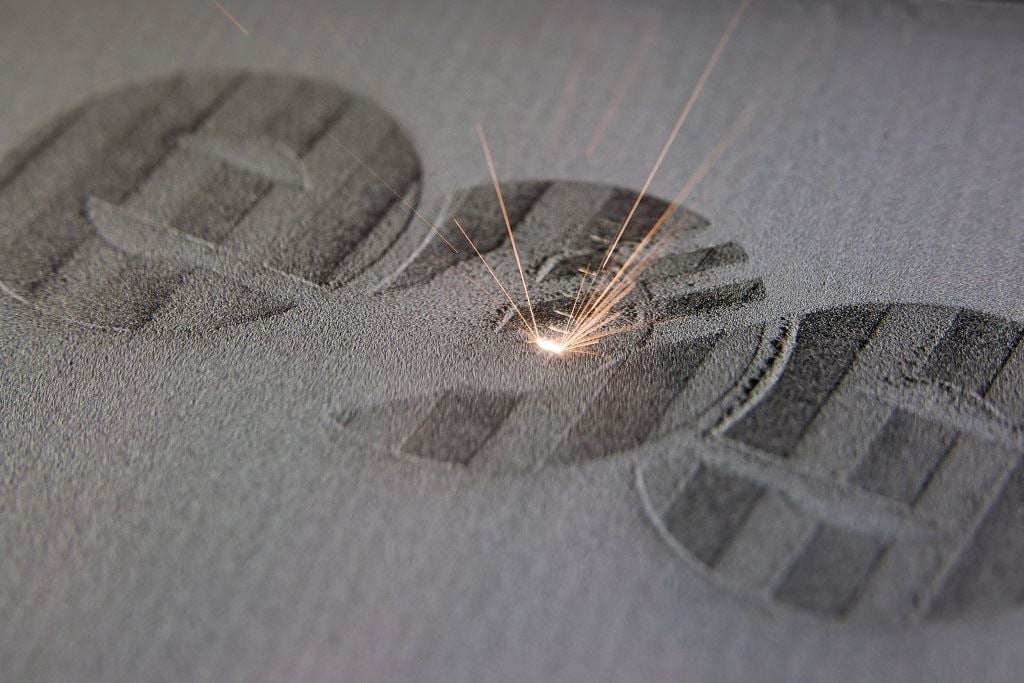

Dr. Hans Langer founded EOS formally on April 24, 1989. He left a history in known industry to follow a more pioneering path, based on using lasers and powder to build things in a new way.

“Lucille Ball died in 1989 and Taylor Swift was born, just to give you some comparison,” Fletcher said to set the scene. “At the same time, German physicist Hans Langer moved back to Bavaria from a job he was doing and started up his own company after leaving an American company called General Scanning. He had a dream to apply lasers to powder materials to create things that had not been created before. Things that would change, in his view at the time, the way things were manufactured.”

As with any slow burning success story, especially in a new industry, the journey wasn’t an easy one. Having started basically alone in a small farmyard, as Fletcher puts it, it took some time to pick up momentum.

“It took 20 years to sell the first one thousand systems, and five years to sell the second thousand, then three years to sell the third thousand. We’re at a current clip to be very close to one thousand systems a year very soon,” Fletcher continued. “Without being too glib, it’s an overnight success story that’s 30 years in the making. Not much happened for the first 25 years or so, and now it is accelerating very, very quickly.”

That “not much happening” was of course still a very busy time. Those two-and-a-half decades built a firm foundation in both business and technology.

In 1997, EOS focused its strategic future squarely on laser sintering technology. The company’s early years had been “dominated by stereolithography technology,” a release on the anniversary notes, but deciding to go exclusive with laser sintering technology shaped the vision — and was a decision that turned out to be “the right strategy, as it turned out.” This also allowed for EOS’ work with both polymer and metal materials.

As the company continued to grow, so too did the 3D printing industry around it. Fletcher noted that the hyped-up period that began around 2011 — starting for him with a headline he remembers that read “Print Me A Stradivarius” — led to what he’s since called the “wow” period.

“Everybody was very excited what could be done with additive manufacturing, but didn’t understand how to exploit that. A lot of experimentation went on. Some of it didn’t work. If you follow the Gartner Hype Cycle, we hit the peak of inflated expectations. Everyone said ‘wow,’ but things weren’t functional in everyday life,” he said.

That hype, of course, led to a lot of disappointment: “for me, this was the so-called ‘woe’ period, and we got back to reality.” Reality, of course, is when the real work begins. Often in 3D printing this means going beyond the ‘cool’ factor of a Yoda head and into the more useful (often more ‘boring’) applications and proofs of concept.

“In the last five years or so, we’re in a good place for real-life applications that can be applied in the mainstream are now being realized. Whether that’s in aerospace, which is clearly a very significant part of that, or medical applications. I go beyond automotive and describe those things that are associated with mobility as having huge potential for additive manufacturing,” Fletcher continued. “So things are starting to get very exciting. They’ve been exciting, but as we hit this reality, and hit the mainstream, things are starting to get even more exciting than they were.”

Now that things are more ‘real’ is when, as he’d mentioned earlier in our conversation, the real acceleration also takes place.

Business is picking up — not just for EOS, of course, but for 3D printing in general. As additive manufacturing goes more mainstream, more users and more applications mean more competition. And that’s a good thing: another sign of a realistic industry. So EOS continues to focus on its own differentiators in an increasingly busy marketplace.

“30 years on, the one-man-band which was Hans Langer has emerged into 1,300 people worldwide, around 200 of which are stationed around North America,” Fletcher said. “We have expanded quickly and anticipate that that expansion will continue.”

Looking at North America in particular, as the continent is a major market focus for the German company as well as being Fletcher’s titular focus, we discussed some of the recent expansion on this side of the Atlantic.

A $2 million expansion in Texas in October 2018 was something of a prelude to the February 2019 acquisition of Vulcan Labs, further expanding operations in Texas.

“We have expanded quickly and anticipate that that expansion will continue. Specifically in North America, we have plans to increase our footprint here with our acquisition of Vulcan Labs and with the development of the P400. We see lots of opportunities to further advance additive manufacturing here directly, both from a development and a production point of view. We will continue to invest in our facilities, probably with regard to production in Texas, and also have plans to create centers of excellence on the East Coast and West Coast,” Fletcher said.

Moving into wider-scope plans, Fletcher also touched on the M300 and P500 systems that were designed, developed, and built in Germany.

“They have a very specific focus,” he said. “Our obsession these days is on industrialization, so bringing additive manufacturing into that arena of higher-volume manufacturing. To do that, we have to transition from where we were, which was machine systems designed and developed for the rapid prototyping space, evolved into machines applied for production, to the design and development of machines that are very specifically for a production environment.”

Production is in sight, and that messaging remains consistent. And it echoes across the industry at large — and, indeed, larger, as Industry 4.0 encompasses a multitude of digital technologies that fit together with 3D printing to create a new digital manufacturing landscape.

“We talk a lot about Industry 4.0, the Internet of Things, the digital twin, predictive maintenance, a lot of very hot-topic things. We are also very conscious that for equipment to be successful in that environment it has to be robust, reliable, and consistent. These are things, I think, that have held ad

ditive manufacturing back: that lack of consistency and ability to make thousands of identical parts on hundreds of similar machines,” Fletcher told me. “Everyone in additive manufacturing can make one good part, but to make it reliably, consistently, robustly, is another thing. The M300 and P500 are direct evidence of work we’ve been doing over several years to bring robust platforms that can be integrated, automated, and installed in more traditional manufacturing environments.”

That messaging carries through every conversation I have had with, as well as all public statements from, EOS executives. It’s certainly refreshing, in a busy industry with a lot of chatter, to hear consistent conversations — and to then apply that consistency to the parts that company’s technologies create.

Take for example a conversation I had with EOS CEO Dr. Adrian Keppler at IMTS 2018. There, he told me:

“Industry 4.0, with the help of 3D printing, can revolutionize manufacturing, how the world is making parts. This is a huge impact to society, also to governments, to countries. You can produce and design anywhere and optimize shipping, lower the carbon footprint. This is a huge opportunity to leverage. We have to be mindful, we have to educate young people to these uses, and to leverage them.”

That outward-looking mentality remains in a statement he made in the company’s anniversary release, where he stated:

“The establishment of complete digital production platforms is a major goal that we are aiming to achieve in the coming years. It’s not just about providing the right 3D printing solutions, but about evaluating, planning, setting-up, and optimizing AM production cells to leverage all the advantages and possibilities of digitalization.”

Digital manufacturing — with focus on the production aspect — is a lantern lighting the path ahead for EOS. With 30 years of business now in the books and business only growing bigger and faster, and the technologies more robust, the next three decades for EOS certainly kick off with great promise.

Happy anniversary to one of the mainstays of today’s 3D printing industry.

Via EOS