![The PowerBelt3D Zero infinite 3D printer [Source: PowerBelt3D]](https://fabbaloo.com/wp-content/uploads/2020/05/powerbelt-top_img_5eb091e938882.jpg)

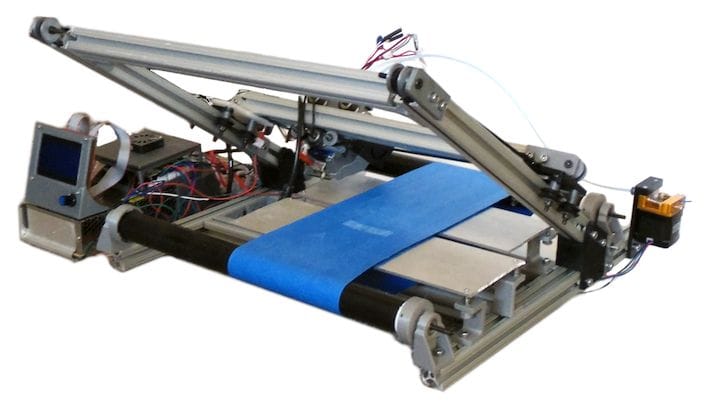

Infinite 3D printing soon to be available to all with the new PowerBelt 3D printer kit.

Infinite 3D printing is a strange concept for most 3D printer operators: 3D prints have a maximum size of the build chamber from the machine on which they’re being printed. Or do they?

There’s an unusual concept that’s been implemented in only a handful of devices called “infinite” 3D printing that changes the maximum Z-axis dimension to, literally, infinity. That’s assuming you have a sufficient amount of material handy, however.

Belt-Based 3D Printing

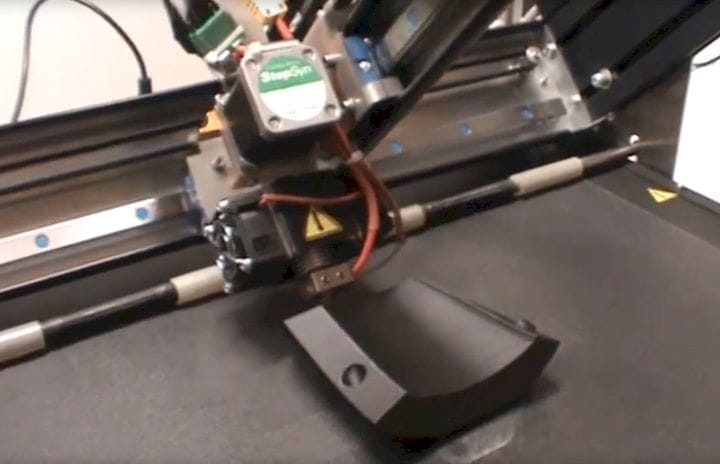

The concept involves tipping the printing plane to a 45 degree angle, and printing these tipped slices on a moving belt. The belt becomes the Z-axis, although it’s not really in the same direction one would normally see it. To imagine what this looks like, lay a stack of cookies along a surface and tip them over slightly against each other. That’s what the printed slices on one of these machines will look like.

![The infinite 3D printing concept [Source: PowerBelt3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb091e981174.jpg)

The “infinite” concept arrives because the belt loops on itself and can thus keep 3D printing forever, so long as material is supplied. That, and a method for holding the infinitely long print coming off the belt.

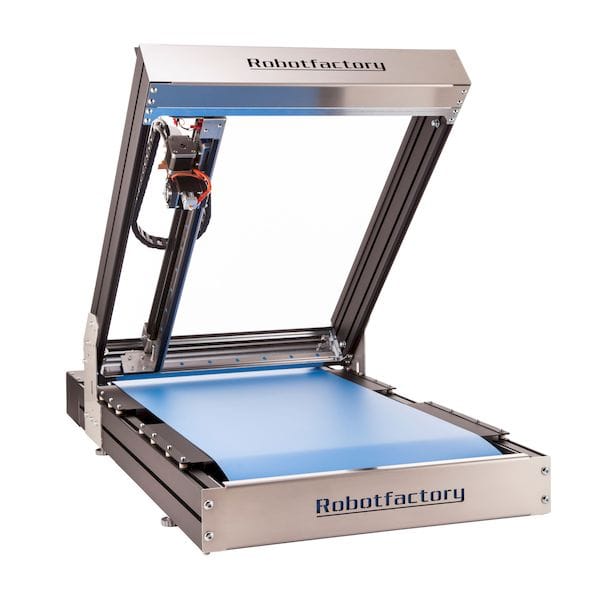

Blackbelt 3D Printer Introduced

I first saw this concept implemented by Blackbelt, a Netherlands-based company that sort of spun off from colorFabb, as one of their staff came up with the idea. Since then the concept transformed into a company and is marketing a 3D printer using the unusual printing process. There’s only one problem: the device is priced at more than US$10K, out of reach for many individuals and businesses.

However, there’s more to the story.

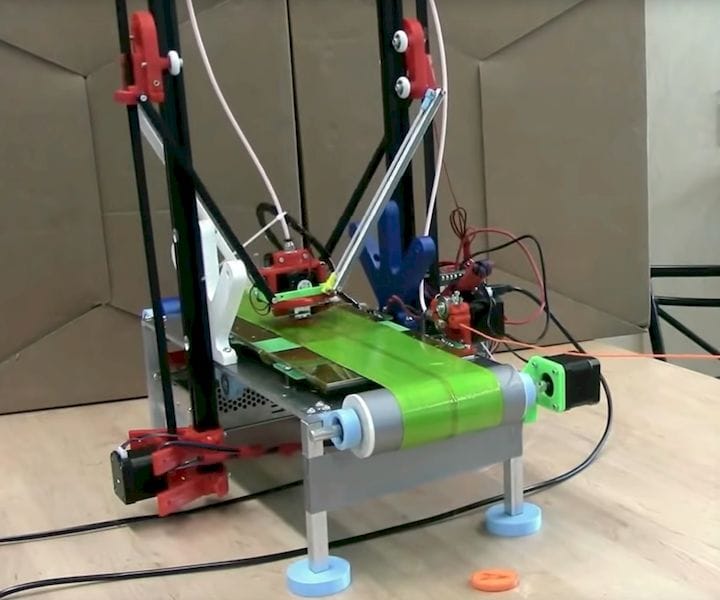

Earlier this year we wrote about a new initiative called “White Knight”, by Pennsylvania-based Karl Brown of NAK 3D Designs to devise an open source belt-style 3D printer using the same infinite printing concept. The design has been uploaded to Thingiverse and it’s said could cost around US$2,000 to build from this design. That’s a substantial cost saving over the Blackbelt offering.

However, now there’s a new offering that should bring the price down substantially. The PowerBelt3D Zero is a low-cost, belt-powered FFF 3D printer kit that is available for only US$399 during their launch.

![The PowerBelt3D Zero infinite 3D printer [Source: PowerBelt3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb091e9c2132.jpg)

PowerBelt3D Zero Specifications

The build volume of the PowerBelt3D Zero is 200 x 170 x infinity mm, as discussed above. This is a bit smaller than either the White Knight or BlackBelt designs, but still quite functional, especially with that infinitely-sized axis.

The PowerBelt3D Zero includes a direct drive extruder and all-metal hot end, allowing for printing of many common engineering materials. Its X-Y motion system uses the Core-XY concept to allow for smooth and coordinated movement.

Of course, the key component of the PowerBelt3D Zero is the belt system. It’s a steel-reinforced GT2 belt that is designed to be easily tightened. This is critically important, as the tighter the belt, the flatter the build surface, and increased probability of successful adhesion during printing.

To be clear, this device is a kit that you must assemble. We asked about the difficulty in doing so, because we’ve seen quite a range of “assembly” in recent kit 3D printers, ranging from 2-3 pieces that need to be erected all the way to bags of hundreds of nuts, bolts, panels, wires and other bits that take hours to assemble. For the PowerBelt3D Zero, it’s said that it should take only 4-8 hours to build.

Once finished, the device is entirely ready for 3D printing, although no material ships with the machine so you will have to supply your own spools of 1.75mm filament.

Infinite 3D Printing Software

I asked about how the slicing software works, because the motion system is very different from that seen on most 3D printers. What software is used? We were told that Blackbelt Cura can be used. This is an open source system based on Cura likely targeted at the Blackbelt system. But it will also work on the PowerBelt3D Zero.

Apparently you can also use ANY slicing system as well. Here’s what you must do: slice the model in the normal fashion, as if for a cartesian device. Then use a special post-processing script to review the generated GCODE and “fix” it to work with the PowerBelt3D Zero. There’s more information on that process here.

Perhaps the most attractive feature of the PowerBelt3D Zero is the incredibly low price, only US$399 at launch, and you can pre-order one right now. We’re told that afterwards the standard price will likely be US$499, so you can save US$100 by acting now.

Via PowerBelt3D