![CoreXY 3D printer motion system reference diagram [Source: CoreXY.com]](https://fabbaloo.com/wp-content/uploads/2020/05/corexy-reference_img_5eb0505acf645.jpg)

3D printers using the CoreXY system are increasing in number, but is this the ultimate motion system?

3D Printer Components

FFF 3D printers have several key elements:

-

The hot end

-

The extruder

-

The print surface

-

The controller board

-

The motion system

For each of these major components there are multiple options. In the case of extruders, there are the Direct or Bowden styles, for example. Hot ends are similar, with multiple designs, and print surfaces are similarly varied.

Motion systems for 3D printers are equally diverse, with the most common being a Cartesian approach where a single motor is dedicated to each of the three axes. These motors work independently to move the hot end to where it’s supposed to be.

There are several alternative motion system designs, with perhaps the most notable — and different — being the delta robot approach. In this design there is no XYZ Cartesian geometry, but instead there is a cylindrical build volume. In a delta system, the three stepper motors used in the motion system work simultaneously to effect movement, whereas a standard Cartesian system has the motors working independently on each axis.

Another common approach is that used most notably by Ultimaker, in which two rigid axes cross the build plane and support the hot end. This approach, like the delta style, has the advantage that the print surface is not moving as is the case in some Cartesian motion system variants, such as that used on the Prusa i3 line.

CoreXY 3D Printers

More recently there has been interest in an approach known as “CoreXY”.

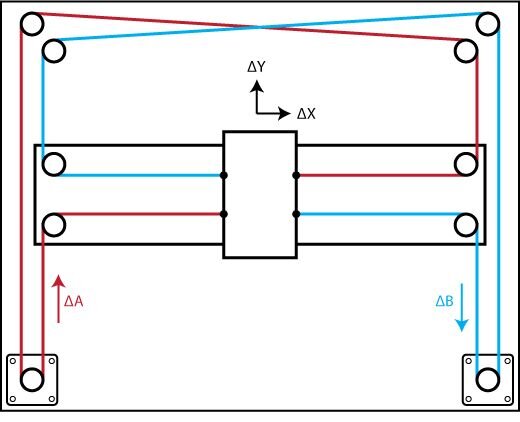

This is an unusual system that is quite different in that it uses two stepper motors simultaneously to effect XY motion. This is similar to the delta approach, but in a CoreXY system, the Z-axis operates independently.

How is this done?

A CoreXY system uses a complex system of two long drive belts that wind their way around through a series of idlers to connect both motors to both sides of the hot end. It’s strange because if you pull on one belt manually, the toolhead moves at a 45 degree angle, not zero or ninety degrees as would be the case for a standard Cartesian system.

There’s also a variant of the CoreXY approach called “H-BOT” in which only one belt is used.

CoreXY Advantages

The CoreXY design is more complex, so no one would use it unless there were advantages, and it turns out there is a major benefit.

Because the XY motors are attached to the belts on the side of the frame, they are not part of the moving portion of the toolhead. This means that the weight that must be moved by the system is quite a bit lighter.

The advantage is that there is less momentum when the motion system must abruptly change direction. In other words, it’s easier for a CoreXY system to make movement changes, which happen very frequently in a 3D print. In terms of print quality, this means effects such as “ringing”, a series of echo-like surface disturbances, tend to go away, as they are caused by an inability of the motion system to completely overcome the momentum of a heavy motor-laden toolhead.

CoreXY Disadvantages

Of course, there are some disadvantages to the CoreXY approach, and they center around the belt system.

The CoreXY belt system is necessarily much longer than a standard Cartesian system’s belts. Long belts are more subject to loosening, as a slight stretch is amplified by the longer length. Often this means the belts must be made tighter, and that’s perhaps more maintenance work to do.

The frame on which the CoreXY motion system is mounted must be quite rigid, otherwise the movements will be inaccurate. Thus a good CoreXY system should be made with a rigid metal frame and strong idlers to withstand the belt tightness.

Another disadvantage is the complexity of the calculations needed to effect the motion, which is much more complex than the simple Cartesian system. For this you likely need a higher-power controller board that can handle the extra load.

CoreXY Future

Like anything in the vast world of 3D printing, the CoreXY approach is a compromise. It may be appropriate for some applications, but not for others. Some tout CoreXY as the future, but I think it’s just another good option to consider.

Via CoreXY