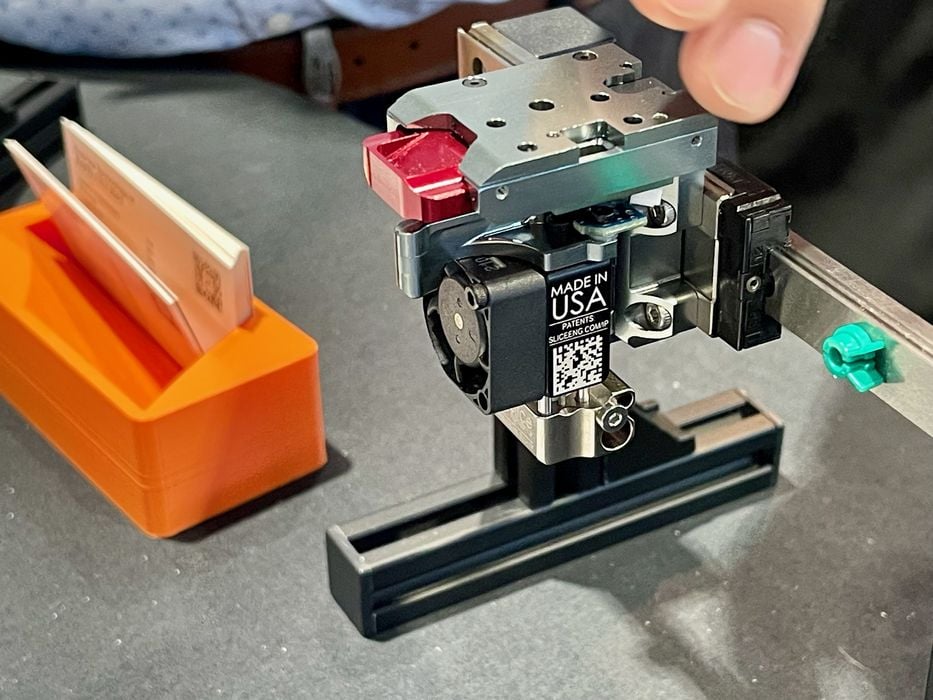

Slice Engineering has released a powerful new professional-grade hot end, the Mosquito Prime.

Slice Engineering is one of the leading providers of advanced hot ends for FFF 3D printers of all varieties. Currently they offer products for hobbyist, maker and professional equipment, with customized kits for selected popular machines.

Their latest innovation is a new hot end for the professional market, the Mosquito Prime. What makes this item different? They bill it as the “world’s highest volumetric flow rate hot end”, and that’s likely true since the specifications indicate up to 116 cubic mm of PLA can be extruded per second. That corresponds to about 500g of material per hour, or half a standard 1kg spool.

How is this achieved? While inheriting much from their popular Mosquito line of hot ends, the Mosquito Prime has a very long melt zone of 61mm. This allows fast-flowing thermoplastics to be exposed to heat for the correct amount of time even at high print rates.

Another factor is the heating element, which is rated at a whopping 150W, far higher than many typical hot ends might use.

Slice Engineering explained to us that there are dual melting zones, one long and one short, which evidently provide an ability for effective heating at speed.

There happens to be two thermistors in the Mosquito Prime, unlike the almost-universal single thermistor found in other hot ends. Two are required because the hot zone is so large portions of it would be too far away for one thermistor to monitor. To solve this problem Slice Engineering uses two thermistors placed so that the entire melt zone can be properly monitored.

Another innovation that adds to the flow rate is a new style of nozzle. Here you can see a close-up image of the filament path, where there are three separate paths to reach the exit point.

This arrangement produces more surface area for the thermoplastic to flow over, enabling more efficient heating. This style of advanced nozzle has been used elsewhere, most notably from Bondtech, and it seems the approach is becoming popular for high-flow systems.

Slice Engineering has designed their nozzle to encourage laminar flow, which should aid in speed and print quality. The design also reduces friction for incoming material.

As you can see, it seems that Slice Engineering pulled out all the stops to make the flow as fast as possible.

There’s more: the Mosquito Prime is designed to be easy to install. It includes a “one clip” style attachment method that should be very easy to lift out when necessary.

Slice Engineering makes the Mosquito Prime in 1.75mm and 2.85mm versions, and pricing starts at US$999.