SPONSORED CONTENT

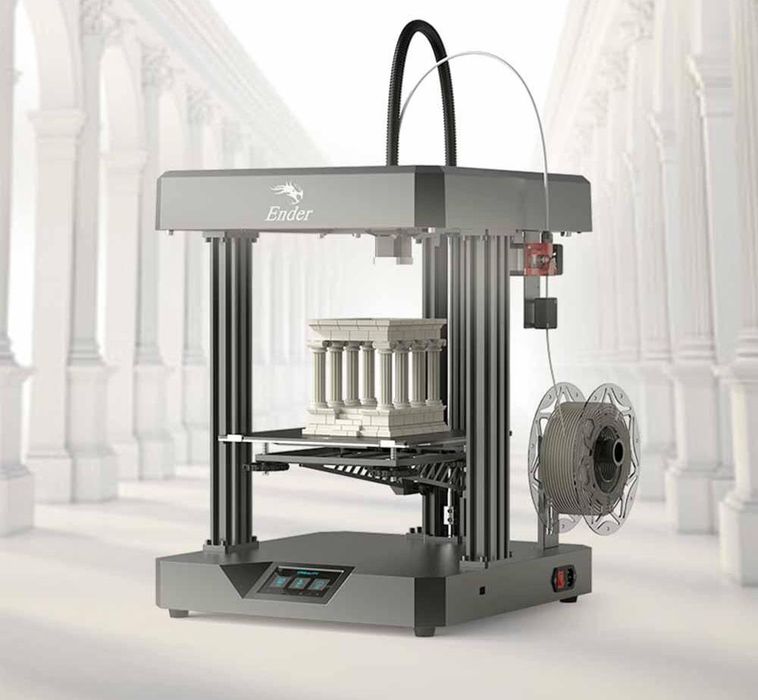

Creality’s new Ender 7 breaks speed barriers with some interesting technological improvements.

The brand-new Ender 7, which was just released last month, has a key feature every 3D printer operator would appreciate: high-speed printing.

The usual slow speed of 3D printing has long been known as a deterrent for many when using the technology. Prints that take hours or even days seem interminable, and the long durations allow plenty of time for failures to occur.

If only 3D printing were faster.

But now, it could be with the new Ender 7.

Creality’s Ender line has been incredibly successful, with the flagship Ender 3 leading the way. Now the Ender 7 joins that brand with a very speedy 3D printer.

The specifications for the Ender 7 include:

- Large build volume of 250 x 250 x 300 mm

- Heated glass print surface able to handle most materials

- Single 0.4mm nozzle, up to 260C

- Dual-gear extruder

- Core XY motion system design

Those are the basics, but the big specification is the print speed. On the Ender 7, Creality says the machine can reliably hit print speeds of up to 250mm/second. For perspective, most FFF desktop 3D printers run at up to 80mm/second, with quite a few in the 40-60mm/second range.

If these 3D printers were run at higher speeds, say over 100mm/second, the prints would have very poor quality because the plastic flow could not keep up. Most desktop 3D printers are simply not built for high-speed 3D printing.

What has Creality done to make the Ender 7 run so rapidly? Let’s take a look at the hardware under the covers of this interesting machine.

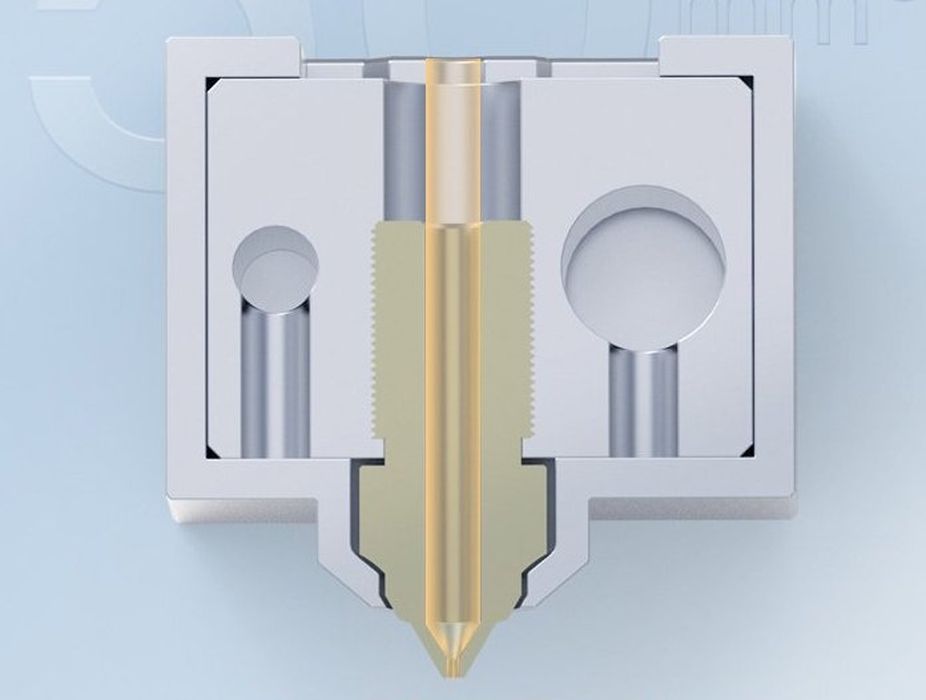

The basic issue with high-speed FFF 3D printing is that the more rapid speed of the filament flow causes a number of issues. Creality has changed several components to address this issue:

- Dual gear extruder, which doubles the “bite” on the filament. Many 3D printers have only a single toothed gear, which can lead to slippage at higher extrusion speeds.

- Beefed up cooling fans, which can freeze soft thermoplastic more rapidly. Since the toolhead moves so quickly, it’s critical to solidify the extruded material faster.

- Larger heat block, which can handle more rapid filament flow. As “cold” filament enters the heat block, it can cool it down at higher speeds because it’s at a lower temperature. The larger heat block holds heat longer.

- Larger melt chamber, which allows for a larger buffer of softened material to account for higher speed consumption of material through the nozzle.

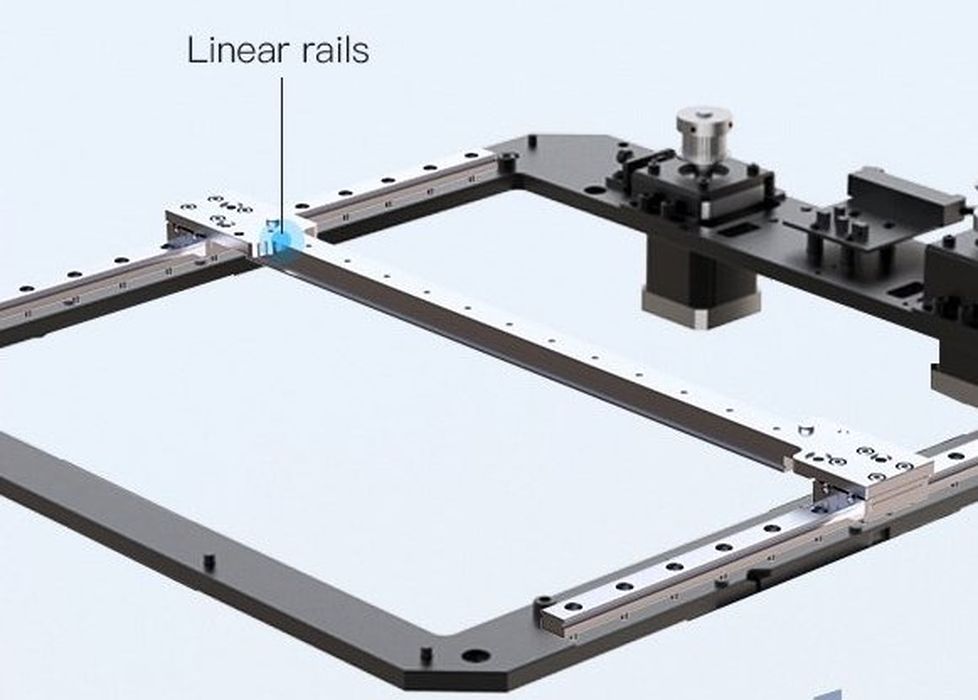

While the extrusion system is critical for high-speed 3D printing, the motion system is also quite important. The toolhead will swing back and forth at a far more rapid speed, and it must do so with as little mechanical resistance as possible.

Creality overcomes this issue by using linear rails instead of the usual roller system used on slower 3D printers. These are purpose-built components for repetitive high-speed motion, and they offer almost no friction when operating.

Creality has also strengthened the stepper motors in the system to a higher power. This, combined with the linear rails, should provide a way to easily move the toolhead at rapid speeds.

Finally, there’s a software improvement. The Ender 7’s firmware attempts to optimize the tool path for high-speed operations. This likely involves avoiding repeated changes in direction that would slow down the toolhead. Obviously some will be required, but to gain an overall speedup, a path optimization takes place.

The Ender 7 is certified to use PLA, ABS and PETG materials, and is priced at only US$699.