We received an invitation to the grand opening of Massivit’s new “Americas Experience Center”.

The new center is to be located in Atlanta, and will hold several “giant” Massivit 3D printers for demonstrations and explanations.

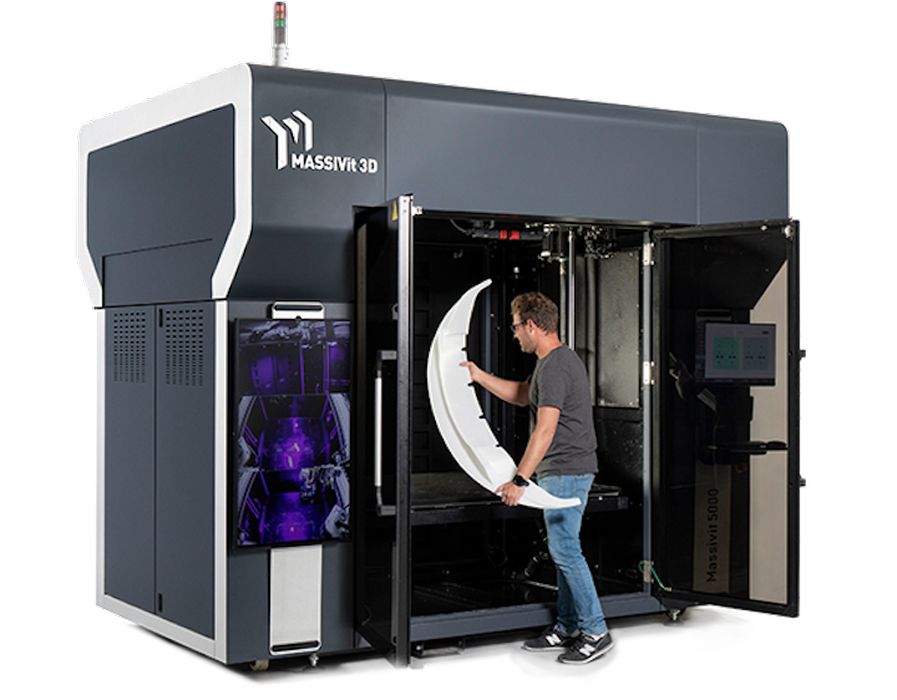

If you’re not familiar with Massivit, it is an Israel-based company that specializes in very large format 3D printing. Their 3D printing process uses a proprietary photopolymer gel, solidified by exposure to UV light.

Liquid photopolymers are commonly used in 3D printing: SLA, MSLA and DLP devices all use the UV polymerization process. However, by using a gel instead of a liquid, Massivit is able to 3D print much larger layers, meaning the prints can be “massively” sized, hence the company’s name.

The typical application for the Gel Dispensing Process, (GDP) is for large-scale models, usually for advertising or display. In other words, advertisers and promoters would be (or should be) interested in GDP technology and how it could be used in their industry. You can read more about GDP in our review of the Massivit 5000 3D printer.

That’s where the experience center comes in.

Industries don’t just suddenly “adopt 3D printing”. It takes a very long time for management within an industry to not only notice, but learn and realize there are benefits.

To many in the tech community, it’s as simple as “build a machine and its amazing capabilities will generate sales.” That approach works only so far, until you run out of tech-savvy clients.

Most of the time clients are specialists in their own business area and don’t know much about 3D printing technology. They have to be educated. They have to be demonstrated. They have to know how to make a business case.

And most of all, they have to be convinced it’s a thing they need.

That’s an incredibly difficult task. For metal 3D printing, it took the efforts of many inside and outside the aerospace industry over several years to finally convince management.

As someone who’s worked in technology for many years, I can tell you there are exactly four phases to introducing any technology within a company:

- “You’re completely out of your mind.”

- “Hmm, you might have something there…”

- “Where the heck is it? Why are we waiting so long?!!”

Those steps may look very familiar to tech readers. Step one takes a very long time, but step 2 and 3 occur very quickly.

The fourth step? Well, it goes something like this:

- “And, what did you have to do with this again?”

Sigh. That’s the story for many who introduce technology to a company. But it’s the price to be paid to make progress.

Making progress is always easier if one can see and touch the technology. Many company managers really don’t understand technology in the same way that tech workers do, and they see things in a very different way. That’s why it is usually extremely difficult for techs to explain a technology to management – and especially to succeed in getting the message across.

The presence of an experience center could very much help get around that barrier by providing a place to see and touch the technology. Tech leaders could bring their non-tech management to the center to get a deep understanding of the product’s capabilities and how to apply them within the business. It could very well open up eyes that otherwise would be shut.

This is a very good move by Massivit, and one that a very few other 3D print companies have taken.

Oh, and we won’t be attending the opening on the 24th due to, you know, virus things. That and our budget.

Via Massivit