Rapidia has had some challenges recently, but it seems they are overcoming them.

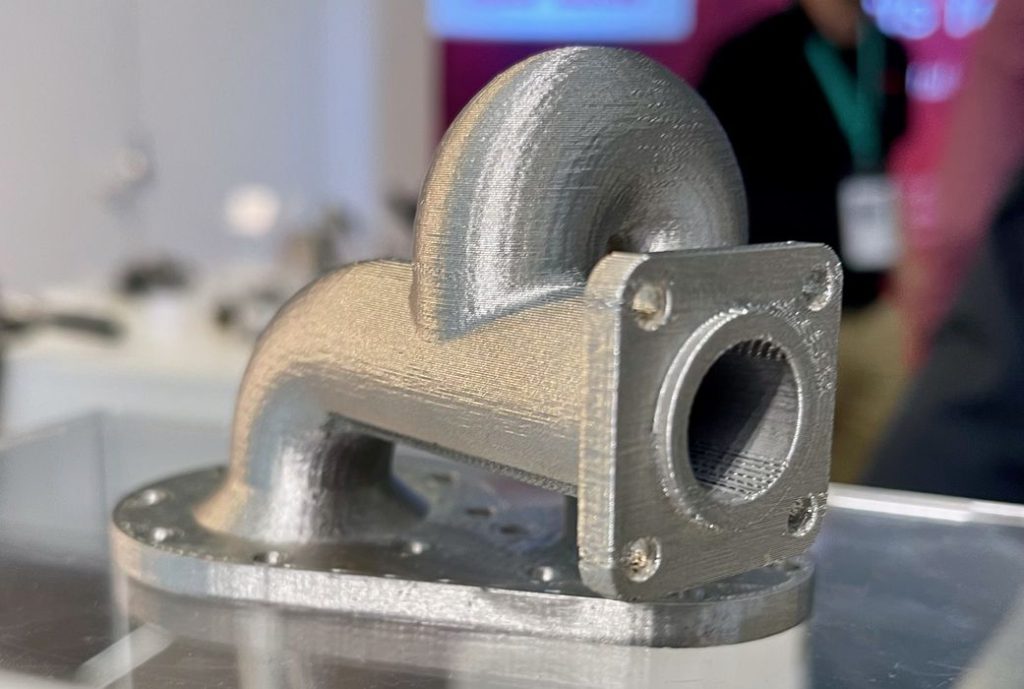

The Vancouver-based company produces a highly unusual metal 3D printing system that uses water. They’ve developed a kind of extrudable paste made from a mix of metal particles and water. “Green” parts printed from this mixture can then be easily sintered into complete parts, and the water simply evaporates. Even better, the evaporated water is entirely benign, unlike the noxious chemicals emitted in some other processes.

We first saw Rapida back in 2019, when they launched their product.

The solution also included the X1F sintering furnace, making the entire system a complete set of equipment to produce metal objects.

This metal printing technology is also interesting because it isn’t powder-based. Typical powder based metal print solutions require highly complex devices, oxygen purging, air-sealed operations rooms and sophisticated HVAC setups to avoid explosions and toxic releases.

Rapid’s paste solution avoids all that: it’s not powder, it’s paste.

As a startup it’s always challenging to get sales going once the bugs in the technology are worked out. One way startups overcome this challenge is to partner with a larger company that doesn’t have similar tech but can leverage their much larger sales and distribution networks.

That’s precisely what Rapidia did, announcing a deal with ExOne to market the technology under the Metal Designlab 3D printer brand.

This sounded like a great arrangement, and it was. At least until something happened.

In August of last year, Desktop Metal acquired ExOne, and subsequently rebranded their products as the X-series.

Except that Desktop Metal already had its own inexpensive desktop metal 3D printer (hence the company name), the Studio system.

Having the Studio system, they had no need for ExOne’s arrangement with Rapidia, and it was discontinued.

For Rapidia, this was a large bump in the road, as it appears the ExOne deal was a major source of sales for the startup company.

What have they been doing since? It turns out several things.

First, they’ve been tightening up their process, and it’s now more efficient. They’ve also improved their furnace technology. A representative told us their cost per part is now lower than Desktop Metal’s equivalent system, and the consumables cost less. Post processing is straightforward, as support materials simply evaporate in the furnace.

In fact, the entire system, including printer, furnace, starter materials and even spare parts for the devices totals only US$190,000. That’s vastly less than the cost of LPBF systems for any company wishing to produce low volume complex metal parts.

The machine is also designed for easy maintenance, and customers can easily do repairs themselves using the spare parts accompanying the machine. Rapidia told us they’ve actually never had to send a tech to the field for service yet.

For sales, the company has had to start over. At the moment they are selling equipment directly to clients via the web in North America, but in Europe they are currently seeking resellers. If any resellers reading this post seek new equipment options, you might want to contact Rapidia.

My suspicion is that eventually Rapidia will engage with resellers in North America as well, as that is the traditional route to corporate sales for this class of equipment.

Via Rapidia