Charles R. Goulding and Preeti Sulibhavi look at a surprising shift in the plumbing industry.

There is a massive shift going on and it has nothing to do with earthquakes.

Many successful residential plumbing companies are pivoting from supplying plumbing and heating equipment to residential homes and buildings, to now providing much-needed HVAC and plumbing to a burgeoning semiconductor manufacturing market. With recent interest rate hikes that make home improvements more expensive, home plumbing companies, such as Ferguson, are making the switch to providing their products and services to semiconductor manufacturing facilities being built all over the country in response to tensions between China and Taiwan.

The connection is not an obvious one, but it is a practical one considering recent events. The CEO of plumbing and heating equipment giant, Ferguson, Kevin Murphy, believes that “the onshoring of chip manufacturing….those are large projects for us in everything from underground water transmission [to] fire protection.”

Plumbing and 3D Printing

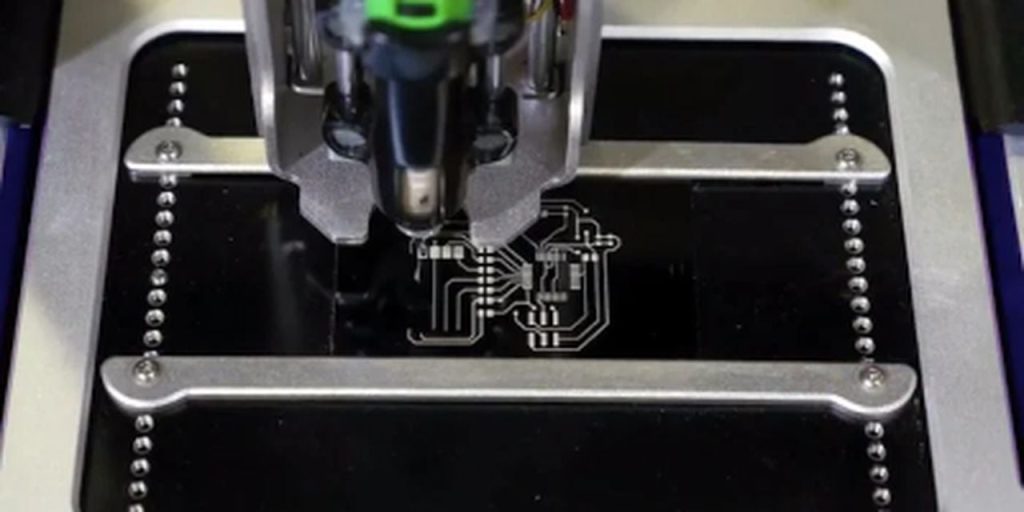

We have previously written about how the 3D printing industry can impact the plumbing industry. There are no limits to how applying 3D printing to plumbing parts and components can improve their quality. Many plumbing companies also handle certain HVAC projects. HVAC systems are also amenable to 3D printing, as we have also covered.

Semiconductors and 3D Printing

There are ways to utilize 3D printing for semiconductor fabrication. We have written about this on Fabbaloo, extensively. With the CHIPS Act being signed into law this past August; the semiconductor industry has been investing heavily in domestic manufacturing. Approximately US$53B was earmarked for American semiconductor manufacturing, workforce development as well as research and development in the Bill.

That is why it is no big surprise that Micron Technology is building a US$100B US semiconductor manufacturing campus in upstate New York. This underscores how the semiconductor industry is reacting to global affairs and increasing demand.

Plumbing companies are taking notice. Ferguson is cashing in on this trend. The group is based out of the UK but does almost all of its business in the US. Ferguson has found that the recent domestic semiconductor production ramp-up has brought in large underground water transmission, fire protection, HVAC and industrial plumbing equipment projects for them. This is a win-win for all parties involved.

Six Construction Trends

There was a piece in the Ferguson press room last year that caught our attention. It highlighted six construction trends that should not be ignored. They are:

- Prefabrication and modular construction

- Sustainable and healthy buildings

- Virtual design and BIM Drive collaboration

- Apprenticeship in addressing skilled trades shortage

- 3D printed materials becoming commonplace

- Adopting IoT technology to increase worker safety

Notice number 5 specifically states 3D printing is becoming more commonplace in the industry.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

There are reasons to give this development the recognition it is due. The 3D printing industry should realize that there are multiple opportunities here. Adapting plumbing components to commercial manufacturing, specifically to semiconductor plants, will require prototyping and time spent designing and developing components for a new purpose. 3D printing will come in handy.