Charles R. Goulding and Preeti Sulibhavi discuss the newly established and groundbreaking “AM Forward Critical Technologies SBIC” fund.

In a groundbreaking initiative, Stifel North Atlantic and ASTRO America have announced the formation of the first-ever private equity fund aimed at bolstering advanced manufacturing capabilities, especially 3D printing, for the aerospace and defense sectors. This trailblazing fund, dubbed the “AM Forward Critical Technologies SBIC,” has been greenlighted by the U.S. Small Business Administration (SBA) and the Department of Defense (DoD) under a new SBA-DoD collaboration.

According to a Gartner survey, aerospace and defense companies reported an average cost of US$184 million per supply chain disruption in 2023 alone. This is a massive problem for the defense industry and a source of defense weakness for the Nation.

The fund represents a novel approach to strengthening America’s defense industrial base and national security by catalyzing private sector investment in vital component-level technologies and production processes. By pairing private capital with SBA-administered leverage, the initiative seeks to achieve its crucial mission without relying on deficit funding, while concurrently supporting American small businesses. We have recently covered the NATO Defense fund and how 3D printing applications are relevant there as well.

CORE Industrial Partners (“CORE”), a Chicago-based private equity firm, in 2022 announced the formation of a new platform with its acquisition of RE3DTECH (the “Company”), a leading provider of additive manufacturing services with a focus on high-volume production parts. CORE’s founder and managing partner, John May, was quoted in Wall Street Journal (WSJ) recently as saying, “A greater intersection of the public and private sector only makes the country better, safer.” CORE has raised US$887 million to back industrial manufacturing for aerospace and defense.

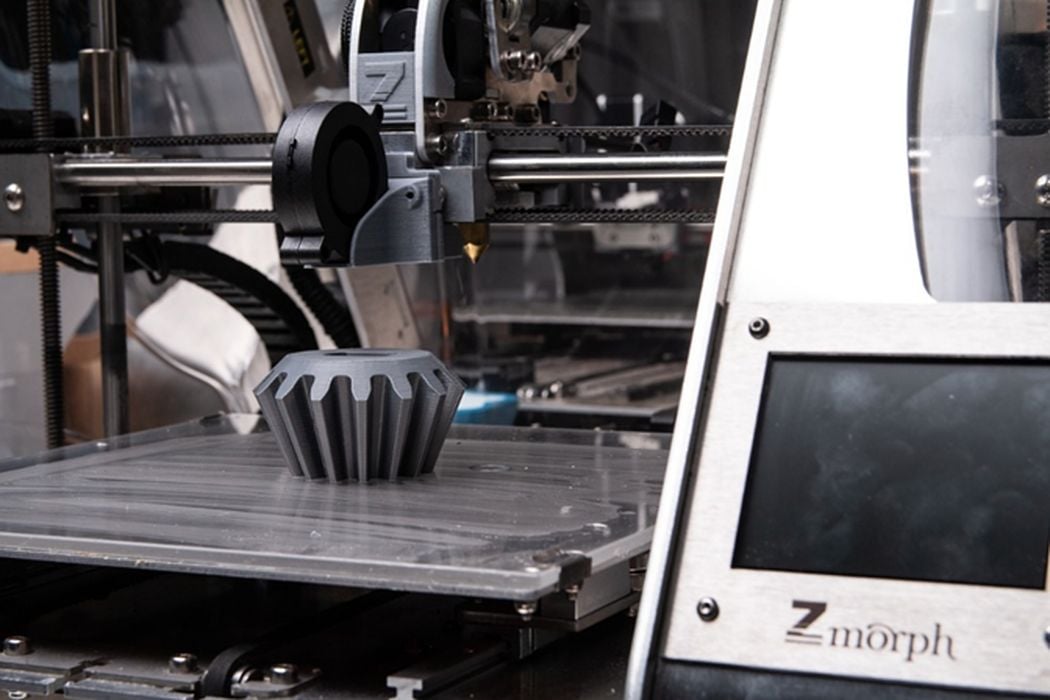

At the heart of this endeavor lies the transformative potential of 3D printing, also known as additive manufacturing (AM). This cutting-edge technology is poised to revolutionize supply chains, enhance manufacturing agility, and bolster America’s defense readiness.

One of the key advantages of 3D printing in the defense sector is its ability to fabricate replacement parts on-site, eliminating the need for lengthy procurement processes and mitigating supply chain disruptions. This capability is particularly valuable in remote or combat operations, where timely access to spare parts can be a matter of life or death.

For instance, during the conflict in Ukraine, the U.S. military has leveraged 3D printing to produce essential components for weapons systems (including drones) and vehicles on the frontlines. This agility has allowed for rapid repairs and maintenance, ensuring uninterrupted operations and minimizing downtime.

Beyond spare parts, 3D printing is also transforming the way armaments, tanks, weapons, and accessories are designed and prototyped for the military. Traditional manufacturing methods often involve lengthy lead times and substantial upfront investments in tooling and molds. In contrast, 3D printing enables rapid iteration and testing of designs, accelerating the development cycle and fostering innovation.

A recent example of this is the U.S. Army’s adoption of 3D-printed grenade launchers. Developed by a small defense contractor, these lightweight and cost-effective launchers were produced using advanced polymer 3D printing techniques. This not only shortened the development timeline but also demonstrated the viability of 3D printing for producing functional weapon components.

Moreover, 3D printing offers unique opportunities for customization and tailoring of equipment to specific operational requirements or individual user needs. This can range from ergonomic grips and handles to optimized body armor designs, enhancing both functionality and comfort for soldiers on the battlefield.

The potential applications of 3D printing in the defense sector extend beyond physical components. Increasingly, this technology is being explored for producing intricate electronics and circuitry, opening up new avenues for embedded sensors, communication devices, and other advanced systems integral to modern warfare.

However, realizing the full potential of 3D printing in defense manufacturing requires significant investments in cutting-edge technologies, materials research, and skilled workforce development. This is where the AM Forward Critical Technologies SBIC fund comes into play, providing much-needed capital and support to small and medium-sized manufacturers at the forefront of this revolution.

By leveraging the expertise of ASTRO America, a leading research institute focused on manufacturing technology and policy, and the financial acumen of Stifel North Atlantic, a renowned investment firm, the fund aims to accelerate the adoption of advanced manufacturing techniques, including metal 3D printing, within the aerospace and defense supply chains.

“This new Fund is important to both our national security and American competitiveness,” said Neal Orringer, co-founder and President of ASTRO America. “Not only will it provide essential financial support to small and medium-sized manufacturers, but it will help modernize key supply chains, helping accelerate adoption of technologies such as metal 3D printing that are increasingly important to America’s defense and aerospace industries.”

The fund’s investment strategy is closely aligned with the goals of the Biden-Harris Administration’s AM Forward initiative, a compact between the White House and seven iconic American lead system integrators. These companies, including defense giants like Lockheed Martin, have identified access to capital as a critical barrier to eliminating bottlenecks, modernizing, and increasing the resiliency of their supply chains, particularly in metal castings and forgings.

By fostering a robust ecosystem of innovative small businesses and supporting the integration of advanced manufacturing techniques, the AM Forward Critical Technologies SBIC fund aims to fortify America’s defense industrial base, ensuring a reliable and resilient supply chain for the nation’s military.

“We are deeply committed to both our unique partnership in the SBICCT fund as well as with the SBA more broadly,” shared Victor Nesi, Stifel Financial Co-President. “The SBA has made remarkable progress in developing innovative ways to reach out, support and nurture the small business ecosystem that is so foundational to our organization.”

As the fund moves forward with its final licensing process and prepares for its initial closing in the coming months, the collaboration between Stifel North Atlantic, ASTRO America, and their strategic partners represents a pivotal step in harnessing the transformative power of 3D printing for America’s defense preparedness and technological edge.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

By supporting innovation, enhancing supply chain resilience, and empowering small businesses at the forefront of advanced manufacturing, this groundbreaking initiative promises to strengthen the nation’s industrial capabilities, safeguard its national security interests, and solidify its position as a global leader in cutting-edge technologies.