Stratasys announced a new 3D printer specialized for 3D printed fashions, the J850 TechStyle.

This is a rather important development in the world of 3D printed fashions, perhaps the most important moment so far. While 3D printed fashions have been around for over a decade, most of the activity has been of an experimental nature.

I’ve seen 3D printed shoes, pendants and similar. I’ve seen 3D printed fashion shows where the most outrageous and impractical designs have been worn by models on the runway. I’ve seen DIY folks experiment with clothing accessories.

Most of these experiments haven’t really panned out. In fact, the fashion runway accessory above was so heavy that it took a couple of people to help the poor model get it on and off.

But one area that seems to have stuck is the notion of 3D printing directly onto fabric. This technique involves tightening down a piece of fabric on a 3D printer bed and then printing on top of it. The polymer is infused into the fabric, mounting it permanently.

Several experiments have taken place using this approach, perhaps most notably in recent times by Susana Marques, who has refined the fabric 3D printing technique using FFF technology.

But there’s one major company that’s been investigating this technique for several years: Stratasys. Almost three years ago the company demonstrated a fabric 3D printing system during New York Fashion Week.

Unlike Marques, Stratasys used their PolyJet system instead of FFF (or, FDM, in their case). The PolyJet process involves fine inkjet heads selectively squirting photopolymer resin on a surface, followed by a pass of UV light to cure each layer as it prints.

In the 2019 demonstration, Stratasys apparently took a stock J750 full color PolyJet 3D printer and stretched fabric over the print bed to achieve fabric printing.

Evidently their experiment proved well, because now they’ve designed an entirely new platform specifically for this type of 3D printing: the J850 TechStyle. They say the device provides:

“Full-color, multi-material capabilities for designs that can be printed direct to fabric, garments, footwear and luxury accessories delivering results that are not possible with traditional methods.”

Stratasys said it is “powered by 3DFashion technology”, which is presumably their set of software, protocols and procedures to implement fabric 3D printing.

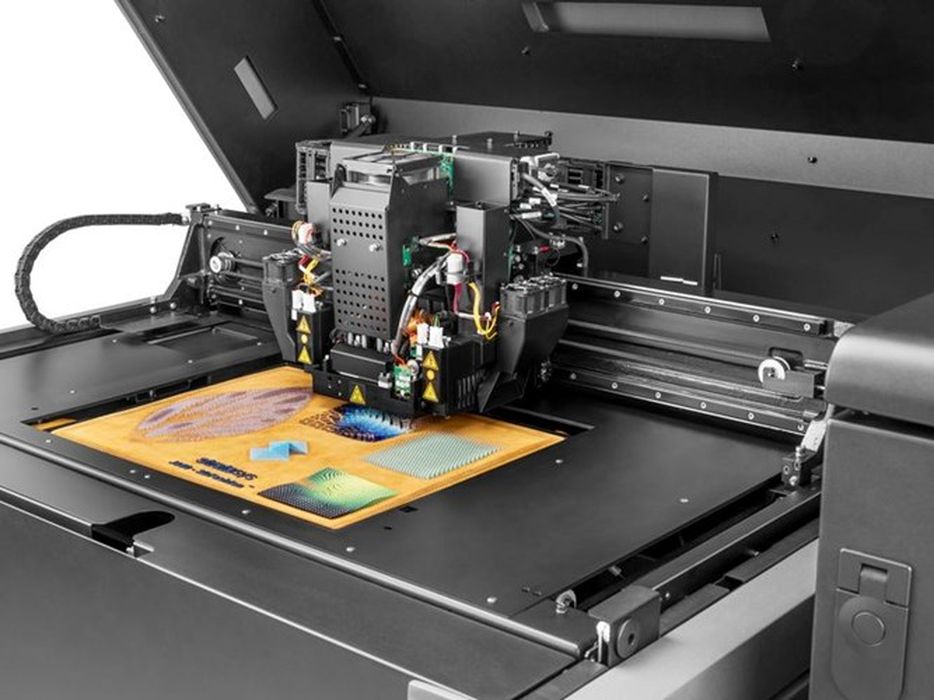

The J850 TechStyle seems fairly straightforward from a hardware point of view. As you can see in this image, the device prints on a sheet of fabric, which according to the specifications is 460 x 360 x 50 mm. It’s attached by stretching it across the build plate and tying down with a specialized collar, as shown here:

Note that the Z-height of the J850 TechStyle is quite low, and that’s because you would rarely 3D print anything very tall on top of fabric because it is flexible and you could create a tangle when flexed.

The J850 TechStyle is able to handle the entire Vero family of PolyJet materials, along with the latest Agilus30 materials. The latter is most interesting, because they provide flexible properties in addition to the full color spectrum. This means that with the device one could 3D print flexible structures on fabric.

I believe this to be an important announcement because it has now made available a commercial device for the fashion industry. While there were plenty of experimental approaches that could be used by the industry, most would only adopt fully supported systems from major vendors. Now Stratasys has one, perhaps the only one for fabric 3D printing.

This could become a significant line of business for Stratasys in the future, given the capabilities of this system, and they may become the “go to” solution for the fashion industry. Ironically, their competitor 3D Systems introduced something like this way back in 2015, but like most 3D Systems announcement in that era, it didn’t go anywhere.

Via Stratasys