Charles R. Goulding and Preeti Sulibhavi foresee increased use of 3D printing in defense applications.

3D printing can potentially help alleviate the labor shortage in the defense industry and increase the speed and efficiency of production.

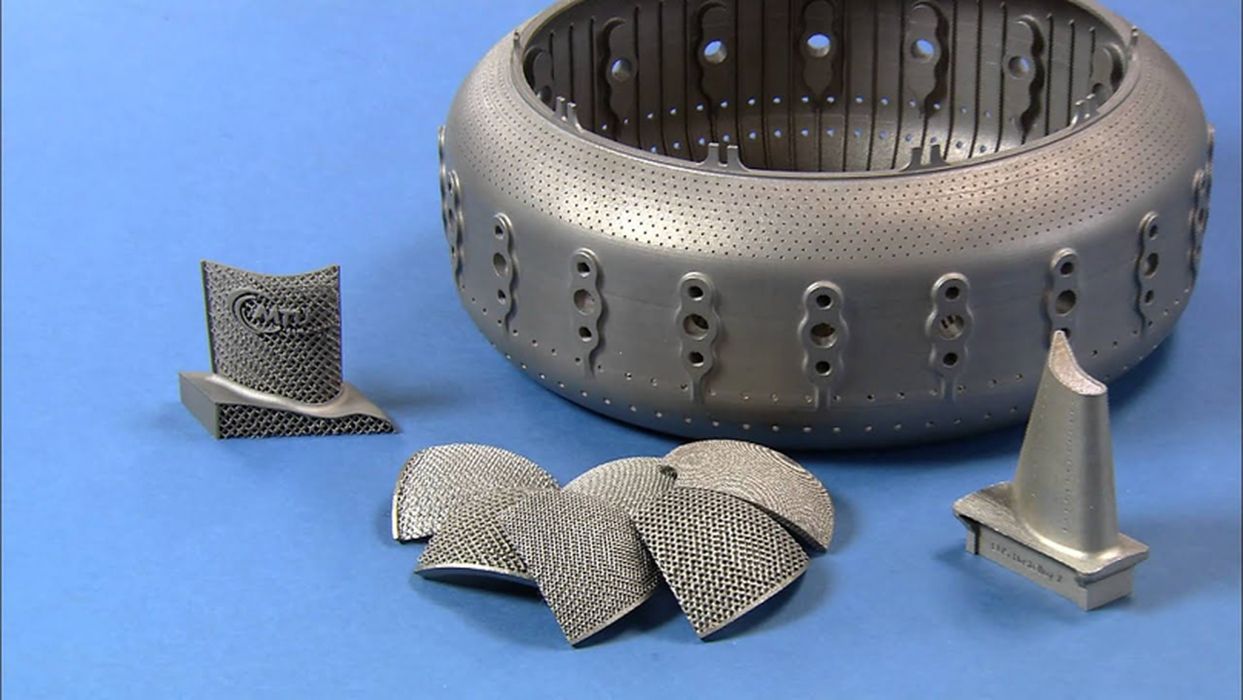

In the defense industry, 3D printing can be used to produce spare parts, prototypes, and even fully functional weapons and equipment. This technology can also enable the manufacturing of complex shapes and designs that would be difficult or impossible to produce with traditional manufacturing methods.

The current labor shortage has affected industry giants ranging from Thales Group, BAE Systems, General Dynamics and Lockheed. Arms makers were already struggling to meet demand, but now with the vast number of vacancies, these industry leaders are making great efforts to recruit specialized talent.

Additionally, 3D printing can reduce the reliance on overseas suppliers and increase the domestic production of military equipment and arms. This can help ensure a secure and reliable supply chain for defense materials, as well as reduce costs and lead times associated with traditional manufacturing methods. Automation techniques can help these companies keep up with demand.

3D printing of military components involves some special issues. Originally, approved components had to undergo extensive first article documentation and testing procedures. Accordingly, they cannot be replaced by today’s 3D printing technology without undergoing the same procedure.

The legacy items no longer in production often lack the original drawing and designs that enable them to be reproduced.

Additionally, the use of 3D printing in the defense industry raises concerns about the security of intellectual property and the potential for unauthorized replication of sensitive military equipment.

The Journal of Air Law and Commerce, authored by Lisa Savitt, Lauren L. Haertlein and Laura Dubois contains a comprehensive article entitled, “3D Printing in the Aerospace Industry: Emerging Legal Issues for Counsel and Insurers.” The article covers technical issues, regulatory compliance, intellectual property, and liability concerns. There were some cross-border comparisons highlighted.

Therefore, careful consideration and management of the risks and benefits of 3D printing in the defense industry is necessary. But overall, the integration of 3D printing technology can only benefit the arms industry, especially during this time of recruiting deficits.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

While the defense industry may be a tougher place to recruit specialized engineering talent, we see this technical worker shortage as an opportunity for the industry not to shrink but to grow by integrating 3D printing and automation into its operations. This will fuel further innovation.