I’ve always thought that generative approaches may be the way for consumers to get into 3D printing, but there’s actually another more important use.

One of the reasons consumers never really caught on to 3D printing was the difficulty in creating useful 3D models. Consumers cannot be expected to learn complex 3D CAD programs and thus had to rely on trolling through near-infinite libraries of random parts to find what they needed. Often, they didn’t.

The promisee of generative approaches developed by a few was to enable consumers to select a few parameters on a base 3D model and have it automatically adapt. However, that hasn’t caught on as much as was expected.

One of the companies producing such generative systems is Berlin-based Trinkcle, and they have a very interesting approach: use the generative system as a B2B tool.

Instead of trying to get consumers to use a generative system, their idea is to have businesses use the same concept.

It make so much sense: in theory, a producer could have a small library of base products that each have the ability to adapt in some way to input parameters. Then the provider could simply “generate” the required products when a client makes a specific request. In this way the business is using the generative system, not the end user.

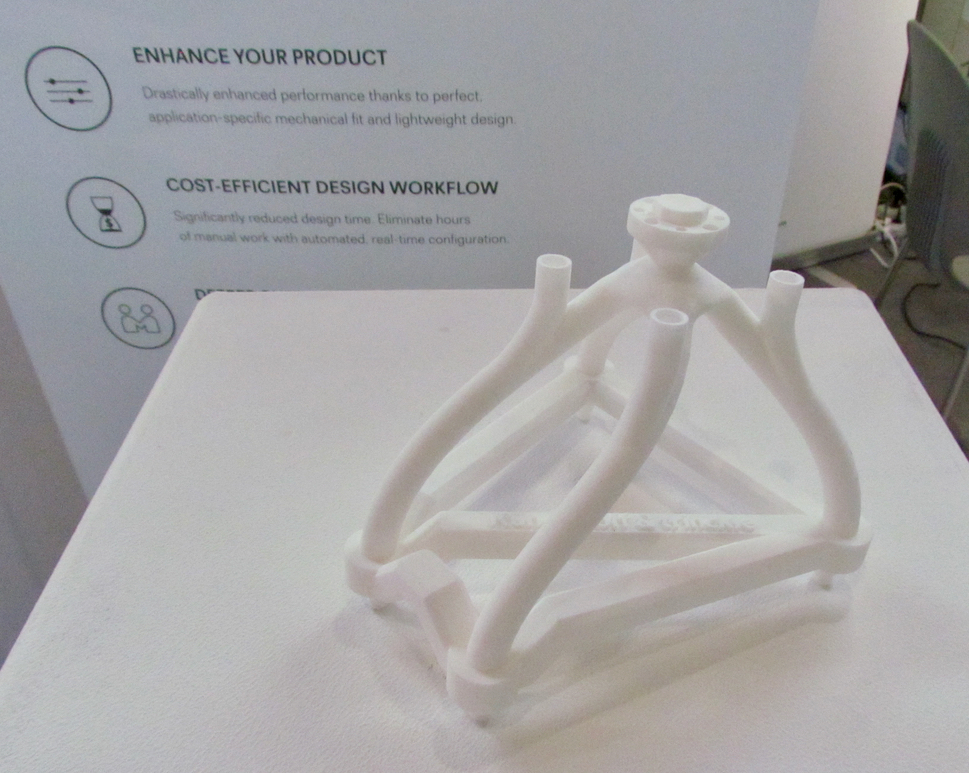

An example product made by Trinckle is this robot arm gripper. Actually, there are a near infinite number of possible robot arm grippers because they must be adapted to fit the specific item they are to grip. They might have to grip a flat item, or curved, large or small, etc.

Trinckle’s system (an example seen at top) permits the generation of a gripper with a specified number of nodes. Each node includes embedded ducting for air pressure that can be quite complex depending on the geometry of the object. You can specify not only the number of nodes, but also their placement and orientation. This enables a designer to very quickly generate a 3D model for a specific robot gripping scenario.

One can imagine this concept being applied to any number of industrial products made by manufacturers, as it could dramatically simplify the amount of design time required to address customer needs.

Trinckle’s approach is to provide such technology to manufacturers who would then offer an online method for their clients to design and request customized products.

This makes so much sense over the consumer scenario because the B2B clients are far more likely to understand what’s going on and have a very specific idea of what they need to make. In addition, the B2B customers have a lot more money to spend than consumers.

I think Trinckle is on to something here.

Via Trinckle