To most people, the name “Ricoh” means photocopiers or cameras. Now, the company is hoping that same name will also mean “3D printing”.

In fact, the USD$18.5B per year Japanese company’s product line includes a wide variety of technical equipment for both consumers and industrial users. Just over a year ago they announced a line of large-format 3D printers with considerable industrial capability, joining the ranks of the major players in the space.

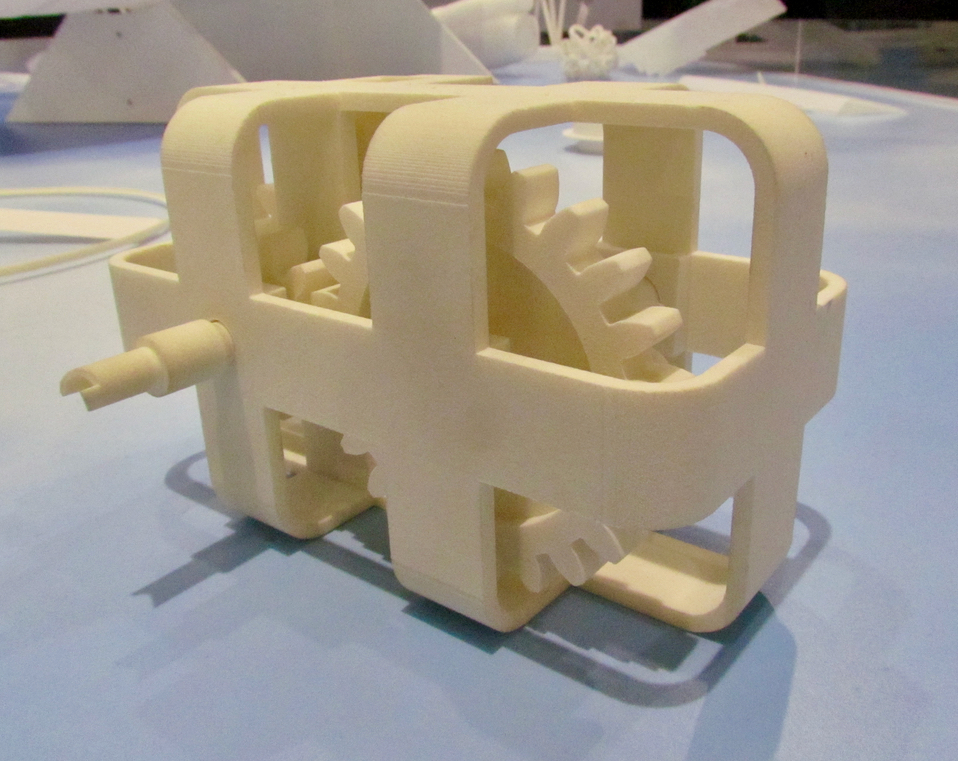

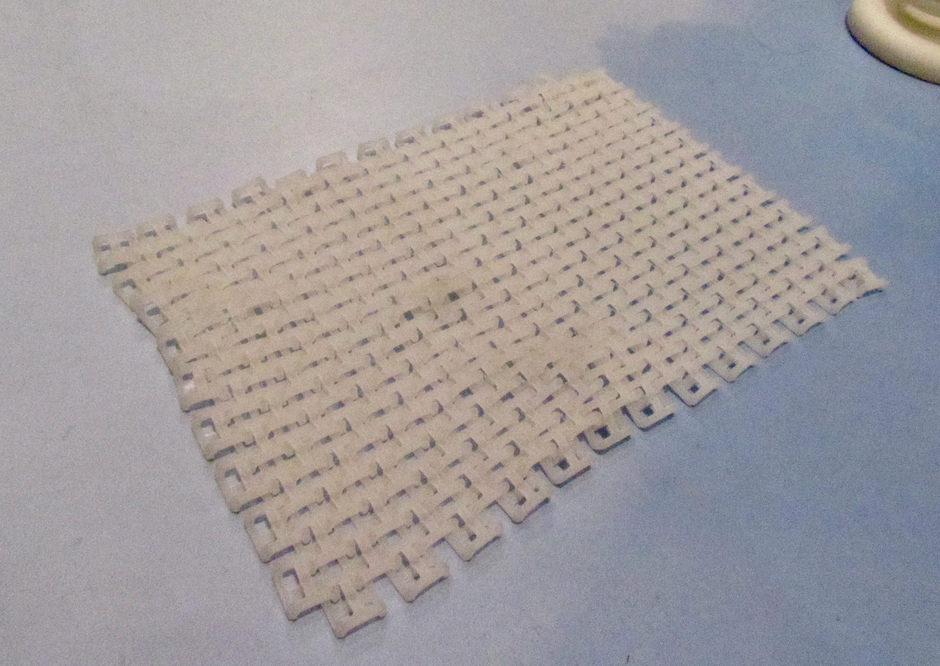

The AM S5500P uses a powder-based system, where a moving laser beam selectively fuses layers of powder repeatedly. In other words, it’s an SLS printer.

But it has a huge build volume of 550 x 550 x 480mm, making it one of the few devices able to 3D print very large SLS objects in materials such as nylon. In fact, the AM S5500P can print in PA 6, PA 11, PA 12, and Polypropylene.

The single 100W CO2 laser can sweep the powder bed at up to 15m / second, but there is another consideration related to speed: cooling.

Large print volumes such as this must have precision heating to ensure optimum laser fusing of the tiny plastic particles. In smaller units, it is easier to ensure consistent heat over the entire build volume, but that’s more difficult when the chamber is the size of Ricoh’s. They’ve managed to handle this issue, but when you finish printing, you have a large build volume full of hot powder.

The large build volume means this finished print will take some time to cool down. Thus, they’ve designed the AM S5500P to have a removable build chamber. When the print completes, you slide it out and replace it with an empty container to immediately start printing the next job. Meanwhile, the removed container can cool down at at leisurely pace.

While the device supports the materials mentioned above, Ricoh does encourage an “open materials” approach, as many of their clients do require peculiar materials in some applications. They offer a materials consulting service for this purpose.

For those wishing to make use of their equipment but cannot afford the approximately USD$500K equipment price (plus related costs such as the room to put it in), you can use Ricoh’s RapidFab service. Based in the UK, they operate two such machines to provide on-demand part printing to clients.

You might be wondering about Ricoh’s entry into this market, and there are several reasons beyond their belief in the need for industry to use 3D printing. One is certainly their breadth of operations, and it would be natural for such a large corporation to provide their clients with a full shelf of industrial products.

But another reason is their considerable expertise in powder handling, as obtained during their decades of experience developing photocopier equipment. Handling powder – with correct heating – is a key element of the AM S5500P.

Via Ricoh Europe