![Dutch PM Mark Rutte with the Additive Industries team [Source: Additive Industries]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4913b7cf.jpg)

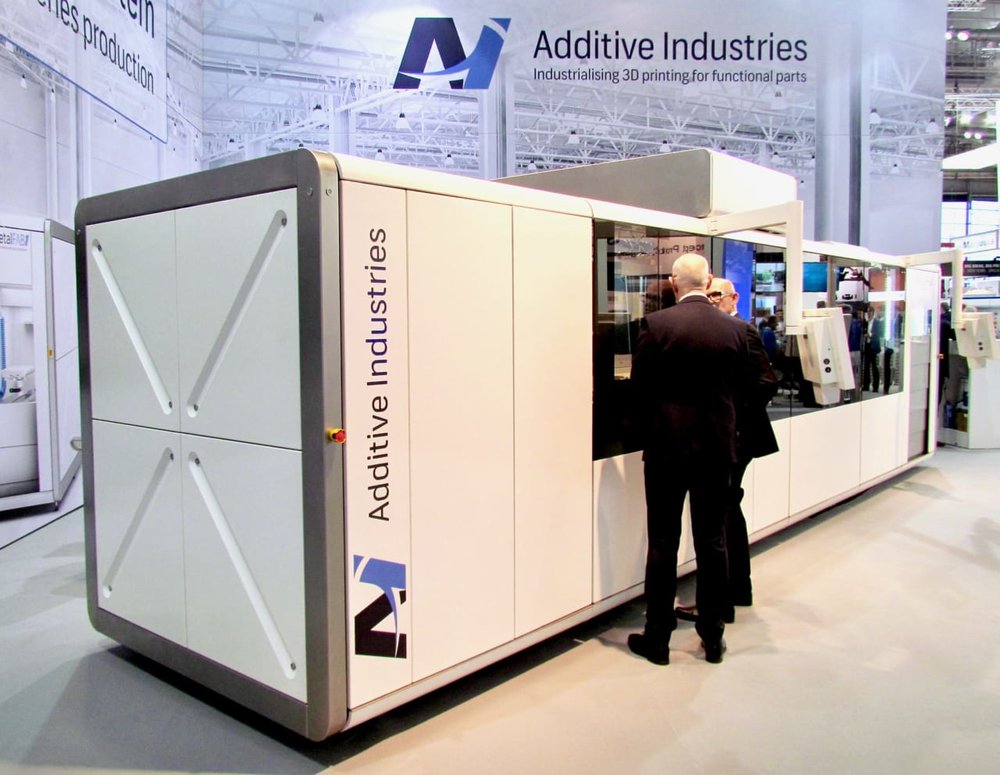

Additive Industries has opened a brand new factory.

The Eindhoven-based startup, which I suppose should not be called a startup any longer, has been rapidly expanding, now achieving a level of business demanding a much larger factory floor.

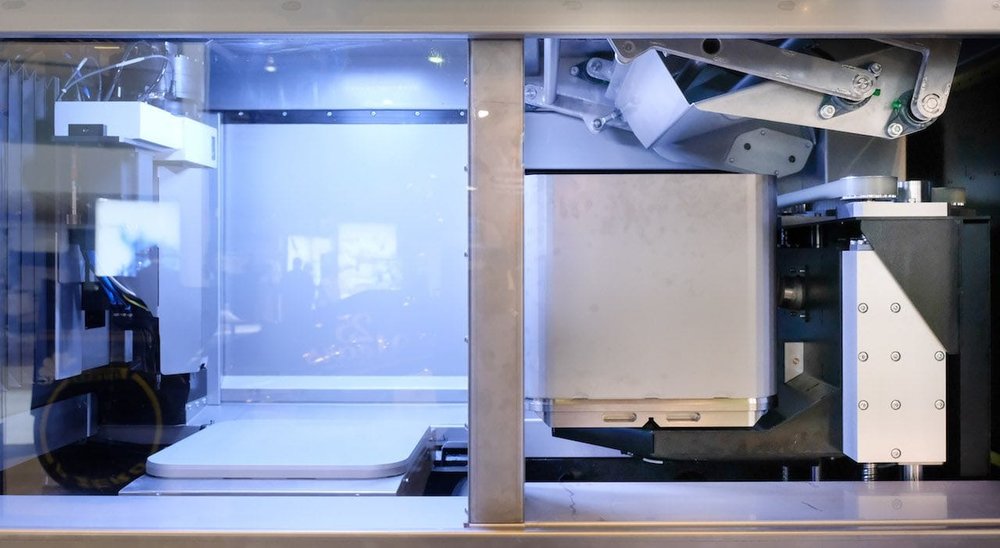

Their equipment is one of the first to recognize the many operational challenges in metal 3D printing. While metal 3D printers have been around for many years, operators have learned there is much more to the business of producing metal 3D prints than simply the printing stage.

In fact, there are multiple steps required in a proper metal 3D printing workflow, such as cooling, removing support structures, heat treatments, and more. Traditional metal 3D printers require these steps but were performed manually.

And as we all know, manual intervention is costly, inconsistent and risky.

Additive Industries’ insight was to develop a modular system that accounts for this complex workflow and attempts to automate as much of it as possible. Their system moves the print along through a sequence of operations that makes the entire process much more efficient and predictable.

![Opening a new 3D printer manufacturing plant [Source: Additive Industries]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4916edbc.jpg)

That concept seems to have caught on, as the company’s sales have been increasing. They’ve developed strong relationships with a number of large-scale manufacturers in Europe and beyond, including aerospace firms and even an F1 team.

But with success comes the requirement to service those demands, and that has resulted in Additive Industries opening a new factory. According to the Additive Industries’ CEO, Daan Kersten:

“This new factory allows us to accelerate our growth and has the capacity to assemble and test up to 100-200 systems per year, which aligns well with our worldwide expansion plans to grow to a Top 3 position in our market.”

The company previously boasted of leaping to a leading position in the market, which might have been a frivolous statement. However, Additive Industries is quite serious in doing so and the opening of the factory demonstrates their ability to do so.

To put this in perspective, if you were to guess their systems sell for, say, US$500k each, 200 systems represents a potential annual revenue stream of US$100M per year for machines alone, not including material or service sales.

![Additive Industries’ CEO Daan Kersten touring their new plant with Dutch PM Mark Rutte [Source: Additive Industries]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a4919b3de.jpg)

It was sufficiently significant that Additive Industries even attracted the current Prime Minister of the Netherlands, Mr. Mark Rutte, to attend their factory opening.

Politicians always know when something important is taking place, and this is no exception.

Via Additive Industries and LinkedIn