![The ZMorph VX [Image: ZMorph]](https://fabbaloo.com/wp-content/uploads/2020/05/zmorphvx_img_5eb0a90b65983.jpg)

I recently caught up with ZMorph’s new CEO for a discussion about multi-tool fabrication on the desktop.

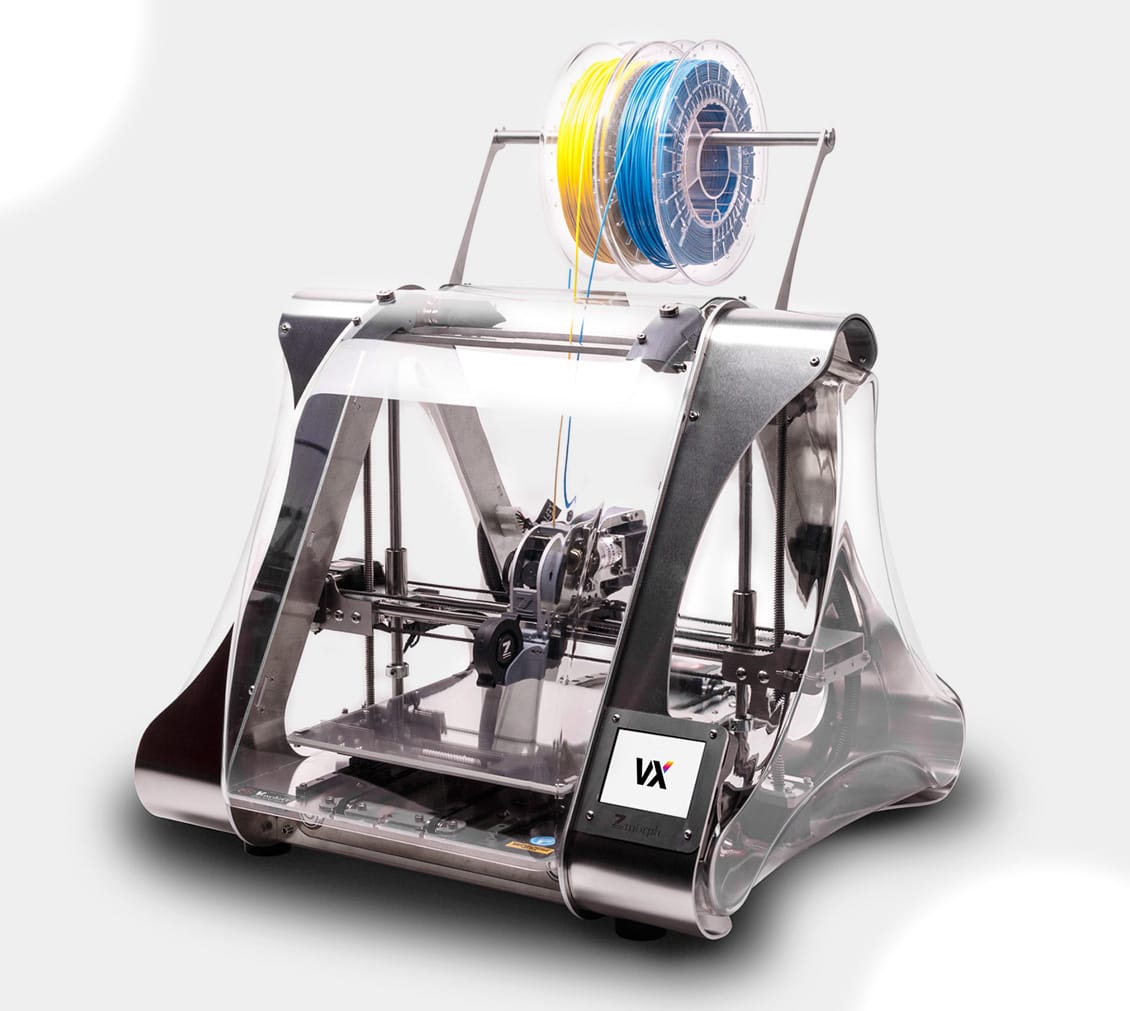

ZMorph is well known for offering multi-tool capabilities. The ZMorph VX, introduced last September, offers “three different fabrication methods and dozens of available materials,” according to its product page.

Maciej Nawrocki, the CEO of the Poland-based company, was kind enough to allow a look inside operations.

How has your career led you to join the ZMorph team?

“I have been working for 15 years in several other industries before joining ZMorph, including electronics, household appliances, and lithium-ion batteries. It was mainly big companies like Tyco Electronics, Whirlpool or Johnson Matthey. My learning from this time was that what I really want is to work in the industry which is in its rapid growth phase and which has a high probability to impact our lives in the mid-term future. I wanted as well to try working in the smaller organization which gives more agility and faster decision-making processes. ZMorph and 3D printing, in general, was my first choice because of several reasons. First is that as a mechanical engineer I was always interested in manufacturing and 3D printing is exactly what may transition the most of the manufacturing industry in the mid-term future. Second is that 3D printing is firmly present in Poland so this is the good place to be if you want to live your career in the 3D printing industry.”

When did you take on the role of CEO?

“I took over the role in December 2017. This was after two months of induction as a COO while I learned the organization and proved myself to the shareholders.”

![Maciej Nawrocki, CEO of ZMorph [Image via LinkedIn]](https://fabbaloo.com/wp-content/uploads/2020/05/maciej_img_5eb0a90c1007f.jpg)

How have you found working with the team and its unique product portfolio so far?

“This is exactly what I was looking for! The team is young but already very experienced in 3D printing. The work atmosphere is relaxed but with care to stay competent, engaged and professional. Our VX model is a great product, it can work as a professional manufacturing tool in many application areas. And not only as a 3D printer but you can actually CNC mill and laser cut and engrave. This is unique offering and I am happy that I have joined ZMorph at the moment when there is such a valuable product in the portfolio.”

What was your level of involvement with 3D printing and associated technologies prior to your work with ZMorph?

“Working in the manufacturing industry for many years, spending the large part of my career in Product Development I have been using additive manufacturing many times. Each new product development process starts with mock-ups and then functional prototypes. I have been then the client of printing service providers as well as a purchaser and user of 3D printers.”

How do you see the place of multitool machines fitting into the overall desktop fabrication market?

“It is a natural fit. But only when you can deliver a professional level of performance from each proposed functionality. And this is where we are with the VX model which can 3D print, CNC mill and laser cut and engrave on a professional level in proven by our engineers’ applications. I am confident there are thousands of 3D printing users who are waiting to discover the power of our CNC and laser toolheads without being aware of it. This is our ambition now to reach out to this creative audience with our offer so they can expand their work with additional production technologies having just one machine on their desk.”

What sets ZMorph apart in terms of its offerings?

“A professional performance level of each proposed functionality. There were many trying to have a multi-tool but these were usually multi-toys due to too many trade-offs in product design, its sturdiness, and reliability. We have made it right with the VX. Try us :).”

What makes this industry appealing to you as an executive?

“Dynamism, growth, great, passionate people.”

What strategies are you putting into place for ZMorph’s operations for the rest of 2018? Looking ahead to the next year? Five years?

“Currently, we are focused on scaling up our production capacities to satisfy growing demands and increasing our visibility to the additive manufacturing community. We have a very good product and it deserves more media visibility which we are going to assure. The next year will be further scaling up and we will start to invest stronger in our new product to appear on the market soon after. Five years is a long horizon but already now we took a commitment to pursue a multi-tool path with growing product portfolio. We will stay though attentive to changing trends and will assure healthy flexibility of our plans and strategies.”