![A Diamond Helmet in an L1 3D printer [Image: Carbon]](https://fabbaloo.com/wp-content/uploads/2020/05/DiamondHelmetinL1printer_img_5eb09d892c540.png)

Carbon and Riddell have announced a partnership centering around customized 3D printed helmet liners.

“Game-changing technology” is all around us — at least if you read as many press releases as we do every day. Most of these “game changers” are weird hype (and often happen to be “world first” introductions created in “state-of-the-art” facilities with “unprecedented” software/hardware/equipment). It gets repetitive; we can write these press releases with our eyes closed. Or a bot can do it.

The “game” of manufacturing hasn’t really been “changed” yet. (It will be as digital manufacturing solutions continue to advance and integrate in Industry 4.0 solutions; but on the whole, it’s still very much in process.)

But what if that “game” is a more literal game — what if it’s football?

American football is famous for a few things; this weekend brings the Super Bowl, full of spectacle, commercials, and (this non-sports-fan is assured) a big game. But that’s not perhaps the NFL’s biggest claim to lingering fame. Concussions are a major issue, as on-the-field collisions can have lasting impact on the players. It’s taken time for concussions to gain the attention they deserve. Helmets weren’t even common in the sport until the 1920s.

One of the earliest companies working with innovative materials to enhance the protective qualities of the headgear, notes Wikipedia, was Riddell:

“In 1939, the Riddell Company of Chicago, Illinois started manufacturing plastic helmets because it felt that plastic helmets would be safer than those made of leather. Plastic was found to be more effective because it held its shape when full collision contact occurred on a play. These helmets were also much more comfortable and had more padding to cushion the head in an impact…. By the mid-1940s, helmets were required in the NFL. … The NFL initially allowed either plastic or leather helmets, but in 1948 the league outlawed the plastic helmet, considering the hard-plastic material to be an injury risk. The NFL repealed this rule in 1949, and by 1950, the plastic helmet had become universal in that league.”

Riddell is back with more innovations, as even plastic helmets haven’t been super successful in keeping head injuries at bay. What does help is athlete-specific support — enter 3D printing.

![A Diamond Helmet with a clear shell to show off the 3D printed liner [Image: Carbon]](https://fabbaloo.com/wp-content/uploads/2020/05/DiamondHelmetClearShell_img_5eb09d89a7fd8.jpg)

The technology has been put to use in an increasing variety of helmets, from the whimsical to the ceremonial to the everyday. Now it’s being put through its paces for professional athlete-specific protection.

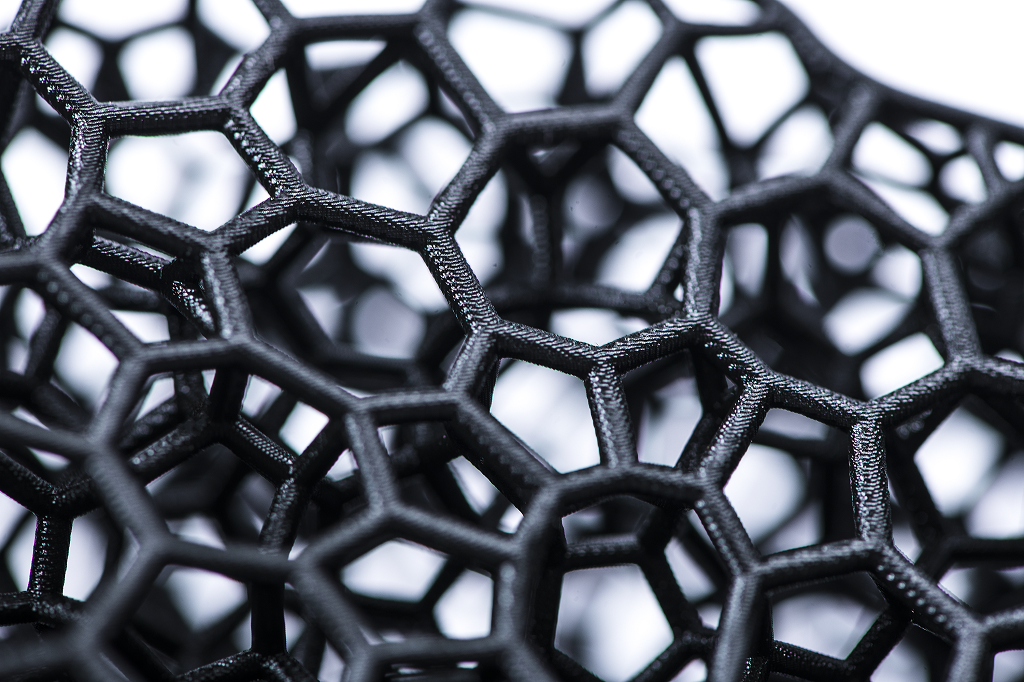

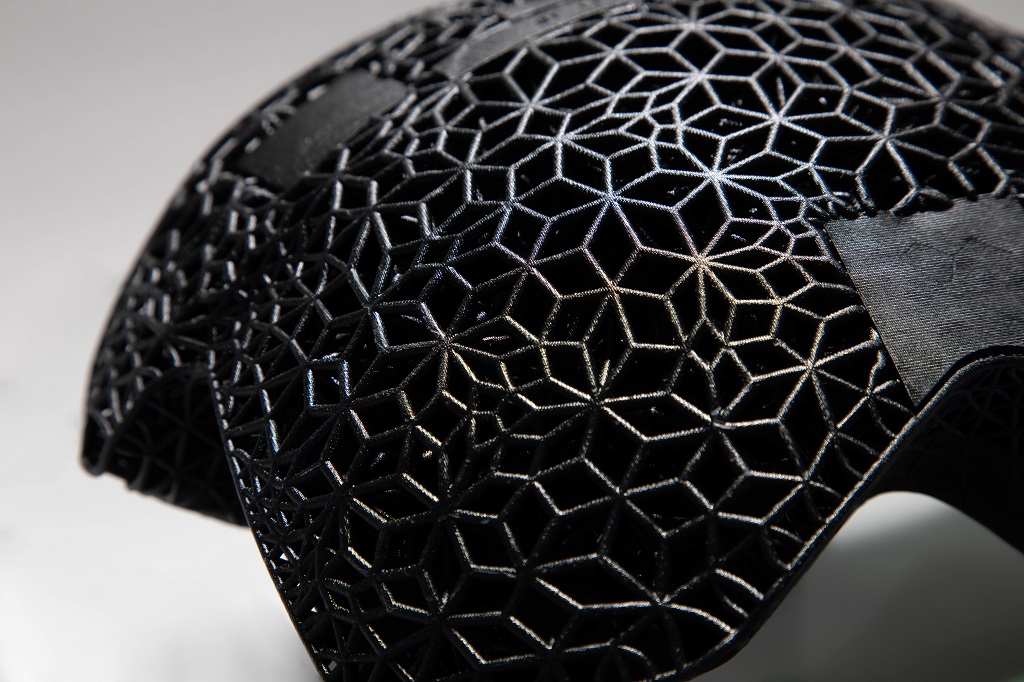

Riddell is working with Carbon and specifically the just-introduced larger-format L1 3D printer intended for high-volume manufacturing to create its SpeedFlex Precision Diamond helmets. These high-tech helmets saw select NFL use in the 2018 season and are set for limited commercial availability (“at the elite level”) starting this year. Key to the helmets’ creation is a 3D printed lattice structured liner made with a custom-to-Riddell resin with Digital Light Synthesis (DLS) tech. This follows Precision-Fit head scanning to ensure the right fit for each head.

Carbon certainly knows its lattices and materials, and these next-gen helmets take great advantage of that expertise. The highly dampening elastomer custom designed for Riddell’s helmets is formed into an intricate lattice — featuring more than 140,000 individual struts based on data from 5-million-plus impacts “captured by Riddell’s smart helmet technology” in the helmet maker’s proprietary database. Further advancing the lattice protection, “the Carbon Lattice Engine leverages physical simulation and optimization techniques to tune structures to further manage both linear and rotational impact energies.”

We’ve seen the importance of these specially-designed lattice structures, as in the 3D printed midsoles Carbon famously created with adidas; the attention paid to design detail is crucial for actual support. Notably, more than 100,000 of these midsoles have now been 3D printed, with millions planned for future years. Large-scale 3D printing is only ramping up — and these new helmets mean Riddell is very much on board for the ride.

“With this partnership, Riddell becomes one of the largest users of 3D printers in the world. We are proud to be at the forefront of digital manufacturing of protective equipment,” Carbon CEO and Co-Founder Dr. Joseph DeSimone said.

Of course it’s not just the execs excited about a major deal (and with high-volume 3D printing involved, it’s a safe bet that the deal is, indeed, major) — this particular advance is most significant for the heads that are set to be protected.

Peyton Manning, a former quarterback so famous he’s probably one of three NFL players I could actually name (again, not a sports person), is a Strategic Advisor and Brand Ambassador for Riddell. Taking that relationship in stride, Manning’s enthusiasm for the potential impact of these helmets focuses on the customization aspect made possible through advanced technologies. He says:

“As someone who’s spent thousands of hours watching film, I know that no two players play the same way. They all have different styles and tendencies on the field, which is another key benefit to Riddell’s Diamond technology. With the SpeedFlex Precision Diamond, players are not only experiencing the latest in head protection, they can also dictate where the helmet is positioned to improve sightlines and maximize field vision.”

Mass customization is a much-lauded benefit of industrialized 3D printing. Game changing? Maybe. Changing the game for a game? Seems to be happening.

The fate of major 3D printing conferences in 2020 is unclear with the ongoing virus outbreak. We have thoughts on what it could mean.