![New 3D printing production usage survey results [Source: Essentium]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09a92b9bcd.jpg)

3D printer manufacturer Essentium just released the results of their recent survey on production 3D printing usage.

The company has been building a rather interesting 3D printer targeted at manufacturers who wish to produce larger quantities of parts by leveraging the new machine’s speedy capabilities. Their new machine incorporates a number of design features that should make it one of the fastest available.

The ability to 3D print at speed could move towards a solution to one of the eternal dilemmas of using 3D printing for production purposes: it just takes way too long to complete a print.

But is that really the case? Essentium sought to find out the answers by issuing a survey they called “Printing at Scale”. Now they’ve released the results of the survey for all to see. We examined their survey to find out more.

The survey was responded to by 114 people who are in positions of authority for acquiring and dealing with 3D printers in their respective organizations. Right off the bat, I have to say that this does color the results somewhat, in that all of the responding organizations already have some level of involvement in 3D printing technology, and thus the survey is of less use if attempting to determine, say, if companies are considering a switch to the technology.

Regardless, there are interesting points in the survey results.

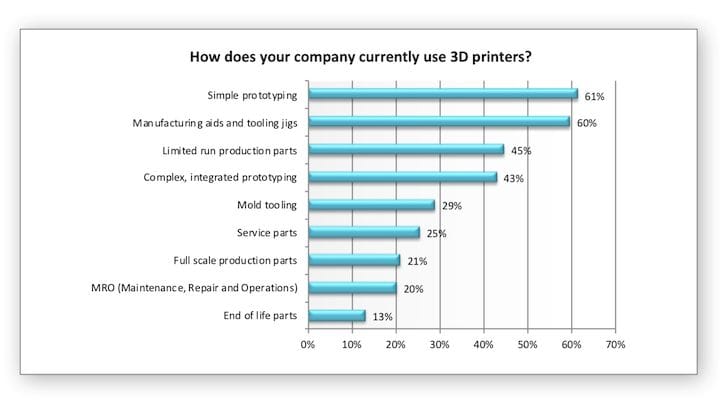

To put the respondents in perspective, some 61% use 3D printing for prototyping, and 60% also use them to manufacture jigs and fixtures. So you can see virtually all of them are deep into 3D printing already.

Surprisingly, some 45% perform limited production runs on 3D printing equipment. This is higher than I would have guessed, but certainly a great use of the technology because the cost to “tool up” for traditional manufacturing technologies is often infeasible at lower unit levels. Meanwhile, there are no “tool up” costs with 3D printing. It seems that many companies have discovered this and are making use of that advantage.

In fact, 83% of respondents claimed they were doing low-volume production runs of up to “hundreds” of parts. There were 5% who claimed to be doing “tens of thousands of parts”, which is substantial. The fact that at least some companies are doing 3D printing at this level is significant.

Some 99% of respondents said they expected their use of 3D printing to grow, with 41% saying “dramatically” so. That’s also significant, suggesting there could be a coming boom in production-quality 3D printing equipment sales.

Two areas seemed to have the most growth potential, according to the survey. Maintenance, repair and operations could double in usage, where companies produce their own spare parts for their own equipment. In addition, “End of Life” parts is set to double, where parts are produced in an ad-hoc manner after the normal manufacturing processes have been shut down. This makes sense, as it enables a company to switch to a digital inventory approach for older spare parts, which could save them significant money.

88% of respondents thought the technology could “save billions” in manufacturing costs if the technology were sufficiently mature, and 91% thought this would eventually happen. Some even expected to be doing print runs of “hundreds of thousands of parts”. This is quite something, considering that these respondents are people who actually use the technology today; they should know what is possible.

However, there are barriers, the largest of which, according to respondents, is the cost of 3D printing, which includes not only the machines themselves, but also the materials. We definitely agree with this assessment, and it’s been the case for far too long.

A lesser barrier, but still significant, is the lack of specific business knowledge on how to properly use the tools, and similarly the need for training of participants in the technology.

There’s plenty more information in this enlightening survey. Thanks to Essentium for doing this!

Via Essentium

Healthcare 3D printing attempts to solve two problems that plague providing care: customization and cost.