Charles R. Goulding and Ryan Donley look at how 3D printing helped PepsiCo design new bottles with a lot to like.

PepsiCo is beginning to release its new 2-liter line in many regional markets. What we like is:

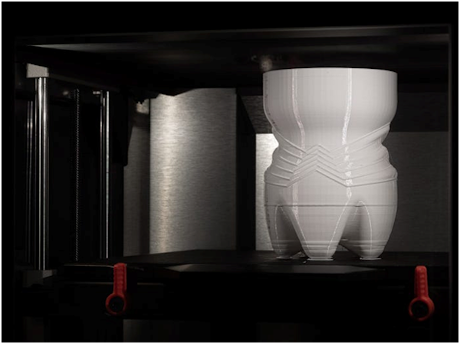

1. The newly designed bottle is refreshingly striking and beautiful.

2. The design has the ergonomic benefit of single-hand gripping.

3. The product was created by a small design team working from home during the pandemic.

4. The product results from using two leading technologies, namely 3D printing and Oculus VR headsets, for design and consumer market testing.

5. With 500 million units sold per year, this product will showcase the power of these technologies to a large worldwide consumer market.

Pepsi and 3D Printing

PepsiCo is a large international food, snack, and beverage corporation that is publicly traded on the New York Stock Exchange and worth approximately $70 billion. The company has been continually innovating across all of its product lines, including the adaption of 3D printing methods and technologies.

From as early as 2011 when PepsiCo first attempted to reinvent Ruffles potato chips using 3D printing to 3D printed Black Panther memorabilia to now redesigning a decades-old bottle design, the company has made considerable strides in reimagining how 3D printing could be utilized.

New Design, Same Beverage

This was an extreme challenge for the design and innovation team at Pepsi. The project started about two years ago and was thought to be curbed when the COVID-19 pandemic started – however, this only led to more innovation on the designers’ part.

A bottled product that has 500 million units produced each year is not as simple a redesign task as many would think. Numerous factors from bottle strength and durability to grip and pouring style all come into play. Hundreds of hours of research were implemented, including the use of VR technology as a resource. The technology was used to allow design iterations to come to (virtual) life and allow feasible user testing without having to fully develop a prototype and run in-person testing. Instead, VR was used as a development tool as well as an interaction tool.

Mauro Porcini, SVP and Chief Design Officer at PepsiCo, offered insight into the development:

“Deciding where exactly to put the grip on bottles for easiest pouring was the product of hundreds of hours of research. A project of this scale in the past would require a laboratory, a workshop, eventually a company that creates the model, it would be very expensive. Today, designers can design from wherever. While VR isn’t that common among design studios or in-house designers yet, it’s where the industry is headed. PepsiCo even did some product testing in virtual reality, seeing how consumers react to the design and how they pick it up. Virtual reality is not just a development tool, but in the future people will interact with brands in VR. The sooner we can understand VR and what the trends are, the sooner we’ll identify opportunities.”

Overall, the project led to significant improvement in bottle ergonomics while maintaining the same quality PepsiCo products.

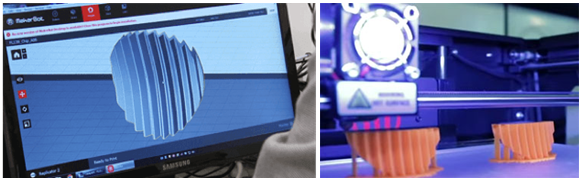

Hundreds of 3D printed prototypes brought these ideas into the physical world for testing. There, the design team could move forward with seeing how these bottles could handle holding pressurized liquids and where thicker plastic might be needed.

“You may design something really cool in a 3D-printed prototype,” says Porcini, “but you put the actual liquid inside, and you lose all the details because of the pressure.”

Utilizing 3D printing in product development may be eligible for R&D Tax Credits.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D credit-eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Since 2016, the R&D credit can be used to offset Alternative Minimum Tax (AMT) or companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in cash rebates that can be applied directly to payroll taxes.

Conclusion

The complete redesign of a major consumer product is normally an infrequent occurrence due to time and cost. Pepsi’s new bottle achievement demonstrates that the design community can do a lot more with less. The end result should empower the entire design and marketing community.