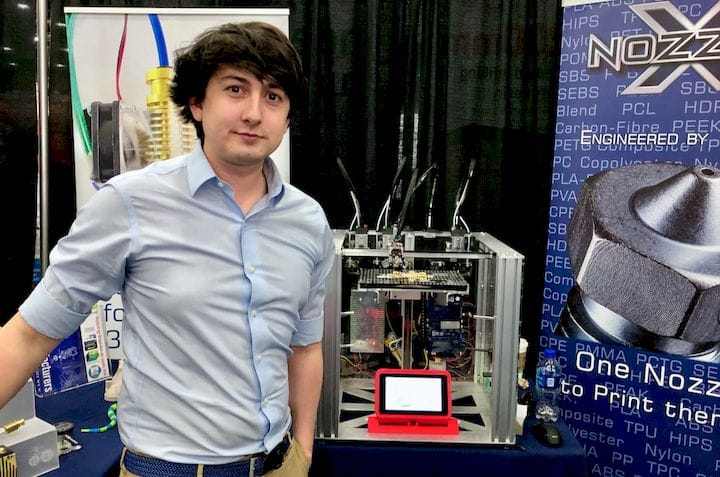

![E3D-Online co-founder Sanjay Mortimer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09563d9b8e.jpg)

We had a chat with E3D-Online co-founder Sanjay Mortimer to find out more about the company.

Today E3D-Online is one of the premier component makers for the desktop 3D print industry, with their hot ends and extruders powering far more devices than you might think. But where did it all start?

Mortimer explains that the company, founded by individuals with manufacturing and engineering backgrounds, originally began as an educational service company, hoping to bring new tech to students by means of teacher training systems. In fact, that’s where the “E” in “E3D” came from: Education.

In the course of this work around 2012, the small startup company was working with 3D printers, specifically the early RepRap Mendel machines. These, Mortimer explains, were “diabolically bad”.

By “bad”, he means unreliable, prone to jamming, etc. At that point they realized that many of the failures were due to poor hot end designs. However, they were too poor as a company to afford purchasing proper — but very expensive — units.

Instead, they decided to make their own hot ends out of pure metal. After all, they had the engineering skill to design them, or so they thought at the time. They designed a metal hot end with a large turned heat sink, which Mortimer explains they discovered was very difficult to make.

Hot End Science

But in testing they realized producing an effective hot end is actually a very complex matter. They discovered that a number of different less-than-obvious factors strongly affected the print result, such as the surface quality of the filament path, for example.

After much testing they arrived at a solution that seemed to work very well, and released it to the public. Of course, that component caught on, as it was both low cost and actually worked very well, unlike many of the competing designs of the time.

Since then they’ve continued to explore the science of hot ends quite deeply. In fact, Mortimer explains they literally have the science behind 3D printer hot ends in a can: they’ve developed a spreadsheet-like tool that can accept as input a variety of factors, and it generates the parameters for a hot end design that will assuredly work properly.

Mortimer says, “We have the formula!”

White Label 3D Printer Hot Ends

Because of this powerful capability, they are now frequently approached by 3D printer manufacturers who require a custom hot end design for their unique system, challenges which E3D is more than willing to take on.

Today a good portion of E3D’s business is white label components used in other manufacturers’ 3D printers. Even when you do see a 3D printer billed as having E3D components, it’s quite possible it is a custom-designed item just for that manufacturer. There’s a good chance you’re using E3D products and don’t even know it!

Having witnessed the entire desktop 3D printing revolution from start to today, I have to say that E3D must be listed as one of the companies that truly helped make today’s success happen by providing high-quality components. And in a way, I think they did indirectly end up helping teachers by ensuring they had functional and inexpensive 3D printers to use in the classroom.

Via E3D-Online

Slice Engineering has developed a new, highly efficient hot end that could be very suitable for use in high temperature 3D printing applications.