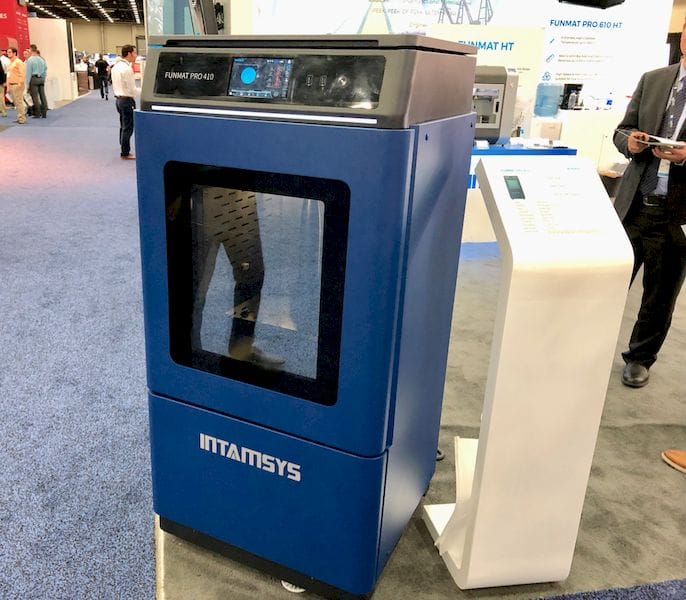

![The FUNMAT PRO 410 High Termperature 3D Printer [Source: Fabbaloo]](https://www.fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eafb37fe1bbc.jpg) The FUNMAT PRO 410 High Termperature 3D Printer [Source: Fabbaloo]

The FUNMAT PRO 410 High Termperature 3D Printer [Source: Fabbaloo]

SPONSORED CONTENT

In the course of writing stories for Fabbaloo for many years, I’ve been fortunate to see firsthand the gradual development of 3D printing technology from rudimentary beginnings to today’s worldwide movement.

But within that enormous wave of additive manufacturing that still is yet to crest, there are smaller ripples that cumulatively add to the massive capabilities of the technology today. I’ve seen several developments that a number of companies pursue that create a more powerful set of making options for users, including the introduction of desktop equipment, the explosion of different metal 3D printing technologies and even the open materials movement.

But one ripple has now become quite solid: high-temperature 3D printing. This is, I believe, an offshoot of the rise of professional 3D printing, in which engineers, architects and industrial designers use desktop 3D printers to produce prototypes of all kinds.

The mantra one hears from these folks is that they will buy the 3D printer “only if it can print in [MATERIAL]”. They wish to have the prototypes made in the same material that the product will ultimately be used for production, if at all possible.

Not too many years ago this was not the case; the number of materials available on 3D printers of the day was quite restricted. And expensive, for that matter, too. But demand continued to rise, and that resulted in a swath of new materials and machines.

The most fundamental technological difference in this area is print temperature. It turns out that many of those “desirable” materials are formable only at temperatures far higher than typical 3D printers can reach.

Eventually, critical mass was achieved and several companies began developing high-temperature machines that were able to use new, in-demand high-performance functional materials such as PEEK, ULTEM, PPSU, PAEK and others. The first machines I saw of this type were functional but rudimentary. But that’s all changed now.

Today we see several very mature companies offering lines of 3D printers that specialize in the 3D printing of high performance functional materials. One of them is Shanghai-based INTAMSYS, who now market their high-temperature 3D printing equipment worldwide.

The company now offers no fewer than four different models offering the ability to 3D print in high-performance functional materials, and one non-high-temperature machine, the FUNMAT PRO. The high-temperature capability is achieved by a clever combinations of heated enclosed build chamber, heated build plate and very high-temperature nozzle.

![The FUNMAT HT high temperature 3D printer [Source: INTAMSYS]](https://www.fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eafb3801e1c8.jpg) The FUNMAT HT high temperature 3D printer [Source: INTAMSYS]

The FUNMAT HT high temperature 3D printer [Source: INTAMSYS]

The “coolest” machines in their catalog is the FUNMAT HT with a maximum nozzle temperature of “only” 450C, while the FUNMAT PRO 410 (an “all-in-one solution, shown at top), offers nozzles that can get as high as 500C, with a 160C print surface and 90C build chamber.

![The huge FUNMAT PRO 610 high temperature 3D printer [Source: INTAMSYS]](https://www.fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eafb380481ca.jpg) The huge FUNMAT PRO 610 high temperature 3D printer [Source: INTAMSYS]

The huge FUNMAT PRO 610 high temperature 3D printer [Source: INTAMSYS]

The “hottest” machine currently in their catalog is the powerful FUNMAT PRO 610 HT, with a searing 500C extruder, 300C build surface and incredible 300C build chamber temperature. At those temperatures, printing of high-temp materials should be easy, as the build chamber and build surface temperatures should ward off any thought of warped prints.

![3D prints in high-performance functional materials made on the FUNMAT PRO 3D printers [Source: INTAMSYS]](https://www.fabbaloo.com/wp-content/uploads/2020/05/funmatOpenmaterialssystem_img_5eafb3807a414.jpg) 3D prints in high-performance functional materials made on the FUNMAT PRO 3D printers [Source: INTAMSYS]

3D prints in high-performance functional materials made on the FUNMAT PRO 3D printers [Source: INTAMSYS]

While the FUNMAT series can definitely 3D print “hot” materials, they can also print the more common materials found in 3D printing, such as PA, PA-CF, PC, ABS, PLA, TPU and others. This is what makes these machines so useful: they can print virtually all available material types.

What’s quite interesting is that the machines are still able to manage layer sizes as small as 0.05mm, making for quite detailed and accurate parts, regardless of the material used. By the way, I should say that the INTAMSYS 3D printer family does not require proprietary filament, and thus the operating costs of the equipment are quite low as compared to some other high-temperature options.

If you require a high-temperature 3D printing option, the INTAMSYS family of high-temperature 3D printers should be considered.

Via INTAMSYS