Artec 3D unveiled the latest version of their powerful 3D scan software, Artec Studio 18.

The company produces high-end 3D scanning gear, and all of them require use of Artec Studio, either to run the scan operations or, more importantly, process the scans after capture.

Artec 3D’s equipment is typically used for reverse engineering, where a part is presented that does not have a corresponding CAD model. The scan of the wayward part can then be imported into a CAD tool where it’s used to “trace” over and develop a true 3D model of the part.

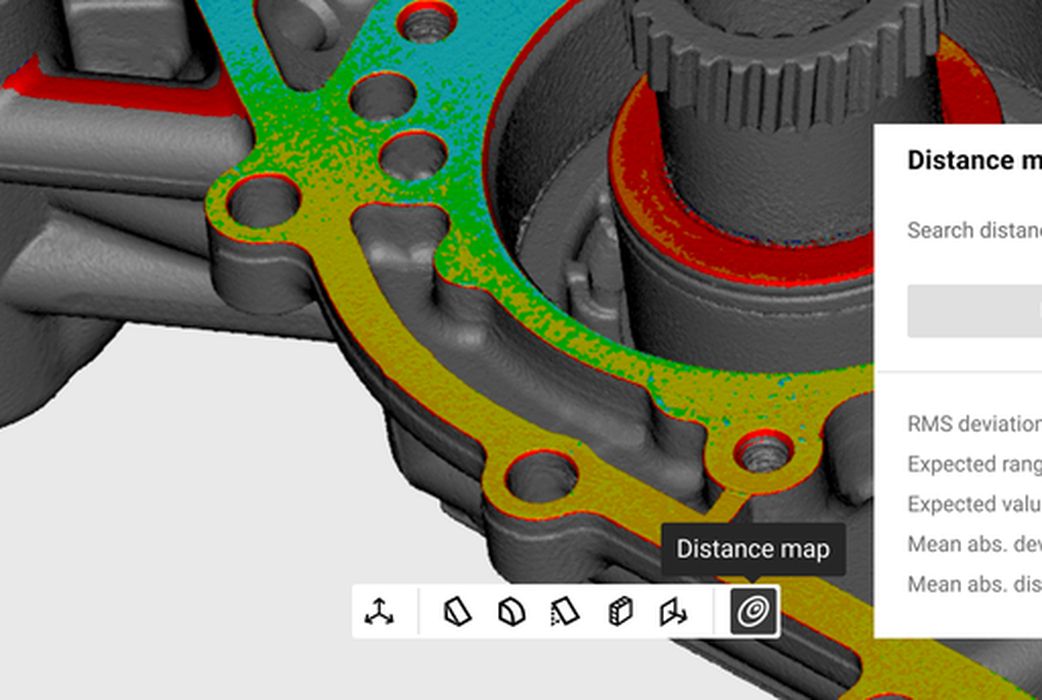

Their equipment is also used for meteorology purposes, where production parts are tested to ensure their geometry is within specified tolerances.

I’ve used Artec Studio myself a few years ago when I tested the company’s powerful Artec Leo handheld 3D scanner. I found Artec Studio 16 (at the time) to be incredibly powerful and somehow able to squeeze out high quality 3D models from even rough captures.

What’s different with Artec Studio 18?

The key feature is something called “Smart Fusion”. It is simply the capability of combining captures from DIFFERENT Artec 3D scanners together in post processing. Normally only scans captured by a single device can be used. However, now it is possible to use multiple scanners to capture an object.

It doesn’t just mean multiple scanners of the same model; instead you can use different models. That means it’s possible, for example, to capture a large scene with their wide-view Artec Ray II device, and combine that data with high resolution scans from their Artec Leo.

Artec Studio 18 also includes new reverse engineering features that should enable more of the development work to take place in the software instead of moving it all to a CAD tool. The new features include functions like automatically thickening walls, and offsetting faces. This should simplify the workflow for reverse engineering parts.

Artec 3D scanners can capture color textures along with the geometry, and this has long been a feature of Artec Studio. However, version 18 now includes an AI-powered color texture processing element. Artec 3D explains:

“Built around neural network decoding, this new feature yields much sharper models with enhanced color contrast. It also allows those who upgrade to drastically improve their overall texture resolution and quality.”

I’m very curious to see how well this performs. Prior color capture was quite good, although if you scanned a person you would be able to determine that it was a scan because of slight aberrations in the color texture. Perhaps with Artec Studio 18 one could capture very lifelike representations?

Finally, Artec Studio 18 has drastically sped up processing. The company said there is “2X faster global registration” and some processing can be done in a single click. They’ve also sped up the HD Mode high resolution processing by 4X.

It sounds that Artec Studio 18 offers some attractive new features that should be considered by anyone using the company’s products.

Via Artec 3D