Charles R. Goulding and Preeti Sulibhavi highlight industries that are flourishing in Houston, Texas.

Texas’ unique geographic location, business-friendly regulatory environment, skilled workforce, and abundant natural resources have made it an economic dynamo to compete with.

Houston is the fourth largest city in the US and is quickly expanding. Built on oil and gas, Houston has just been ranked as number one for International Business. There has been organic growth in the green energy industry as well as some other strong markets (i.e., shipping/trade, technology, manufacturing, engineering and healthcare, etc.).

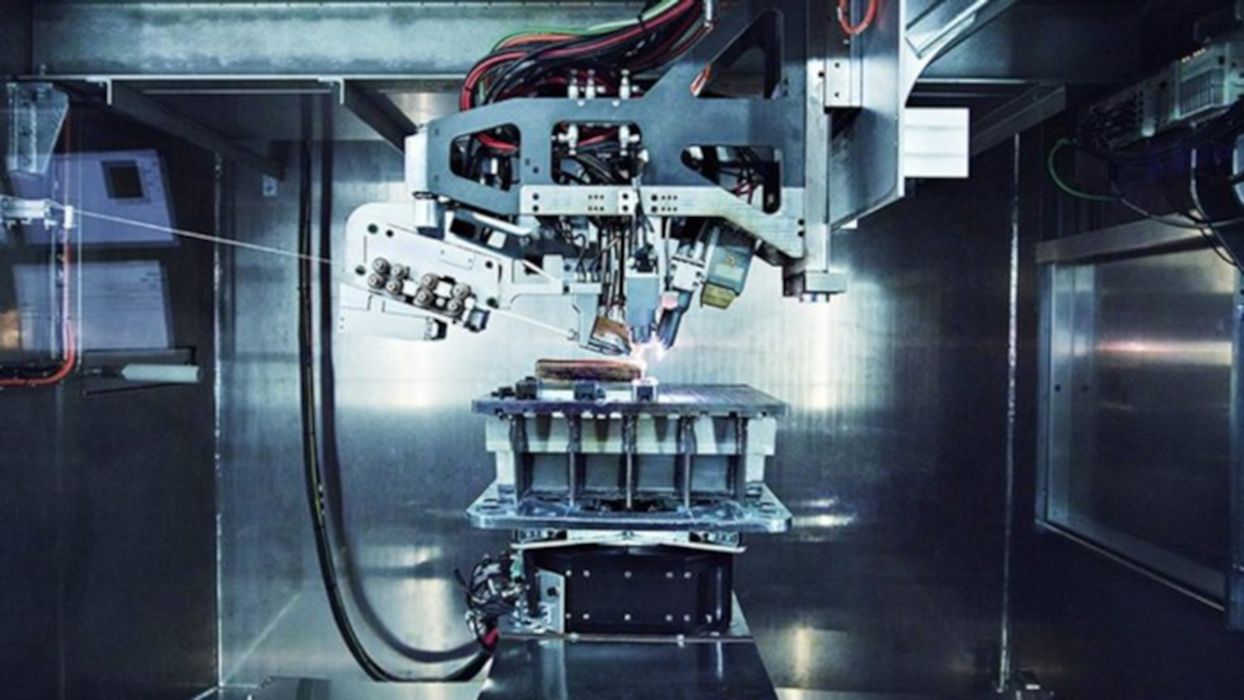

Houston is renowned as the Energy Capital of the World. However, recent trends in green growth in the City have led people to give it the moniker, “The Energy Transition Capital of the World.” The transition being key to Houston’s current and future energy success. There is rapid growth in the green energy industry, especially with the whole host of tax incentives introduced via federal and state bills passed in recent years. The 3D printing industry has demonstrated its ability to pivot toward different markets in terms of flexibility in design, ability to handle a variety of materials, and the agility to work on-site if need be. These qualities are what have enabled the 3D printing industry to permeate the energy, shipping/marine, aerospace/defense, and healthcare sectors.

Oil & Gas

Traditional oil and gas is what Houston has been singularly associated with in the past. Major oil companies such as Chevron, BP, ExxonMobil and Shell all have large operations in Houston, Texas.

In addition, the three leading oil and gas equipment suppliers, Halliburton, Schlumberger and Baker Hughes are headquartered in Houston.

The oil and gas industry has been focusing on new technologies to meet the global demand for energy but in a sustainable and eco-friendly way. In 2021, the American Petroleum Institute (API) issued the first edition of Standard 20S that supports the use of 3D printing for the oil and gas industry by identifying requirements for quality, specifications for industry applications and protocols for training and inspection (quality control).

Alternative Energy

The oil and gas industry can segue into alternative energy sources. The technical skills related to production processes such as offshore drilling and land-based drilling are directly transferable to offshore wind and geothermal energy production. Solar projects require large volumes of brackets and fasteners, which are suitable for 3D printing.

We have covered how the 3D printing industry is helping make alternative energy projects more affordable now so that they are serious, economically viable options. Using 3D printers to create replacement parts or to repair alternative energy equipment is a way to avoid supply chain delays as well.

Many new technologies like direct carbon capture are coming of age where 3D printing, and its generative design and digital twin capabilities can be incorporated into the project design as original equipment.

Shipping/Marine

In the marine industry, projects often require equipment repair or maintenance on site. This is where submarine drones can be useful. Blue Robotics, a California-based tech company, is making this happen – with help from Sculpteo’s 3D printing workflows. Described as small GPS-guided solar-powered boats, these submarine drones can go the distance in the ocean. The team at Blue Robotics used 3D printers to create thrusters that could stand up to the water pressure and salt water in the ocean, because there were no existing commercially available-available options at the time. The design the team came up with made their thruster so dynamic that both the motor and propeller were different than most because they were designed in a way that let water pass through both parts (even the motor) and that’s what allowed their drones to run fully immersed in water.

Aerospace & Defense

Houston is home to the large NASA Space Center complex. The aerospace industry is one of the most widespread users of 3D printing. That includes taking 3D printers into outer space. We have covered many of the leading aerospace companies’ projects and acquisitions and how some of them have been experimenting with 3D printers as well.

Healthcare

In Texas, there has been substantial development in healthcare technologies. That includes 3D printing. Seagull, a Dallas-based tech company, has been experimenting with 3D printers to help the healthcare industry better visualize the effects of various diseases on human organs and tissue. Seagull expects 3D printing to play a significant role in the future of healthcare in terms of customization of MedTech, bioprinting, and with drugs/medication regimens as well. We have also covered the biomedical, innovative breakthroughs underway at Rice University, the top-tier school located in Houston, Texas. The biomedical team at Rice is using bioprinting to help patients with chronic medical conditions “regenerate cells” and find hope for a healthier future. From cancer to orthopedics, bioprinting has been a real game changer for the healthcare industry – thanks to researchers at Rice University.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

“Houston, We Have a Problem”

But it is a high-class problem, as so many industries are finding homes in Houston, Texas. Leading industries such as shipping/maritime, healthcare, and aerospace/defense have settled there. 3D printing companies around the world should keep Houston on their radar for tapping into new markets and recruiting top talent.